The 1998 GMC 2500 Classic is a robust and reliable truck, popular even today for its durability and straightforward mechanics. For diagnostics and emission testing, it utilizes an On-Board Diagnostics system, specifically OBD2, which became standard in vehicles around this era. A crucial component for the OBD2 system to function correctly is its fuse. If you’re experiencing issues with your OBD2 scanner not connecting or other electrical problems, a blown OBD2 fuse might be the culprit. This article will guide you through locating, understanding, and troubleshooting the OBD2 fuse in your 1998 GMC 2500 Classic.

Understanding the OBD2 System and its Fuse

The OBD2 (On-Board Diagnostics II) system is a standardized system in vehicles that provides access to various vehicle subsystems’ health and diagnostic data. Mechanics and vehicle owners use it to diagnose problems, monitor performance, and ensure vehicles meet emission standards. This system requires power to operate, and like many electronic components in your truck, it is protected by a fuse. This fuse is designed to blow and break the circuit if there’s an electrical overload, protecting the more sensitive components of the OBD2 system.

Locating the OBD2 Fuse in a 1998 GMC 2500 Classic

Finding the OBD2 fuse is the first step in troubleshooting any issues. In a 1998 GMC 2500 Classic, the fuse box you need to access is typically located inside the vehicle.

- Driver’s Side Location: The primary fuse box is usually found on the driver’s side of the dashboard.

- Accessing the Fuse Box: Look for a panel on the side of the dashboard, often accessible when the driver’s side door is open. You might need a small screwdriver or your fingers to open the cover.

- Fuse Box Diagram: Once you’ve opened the fuse box, you’ll find a diagram, usually on the inside of the fuse box cover. This diagram is crucial for identifying the correct fuse for the OBD2 system.

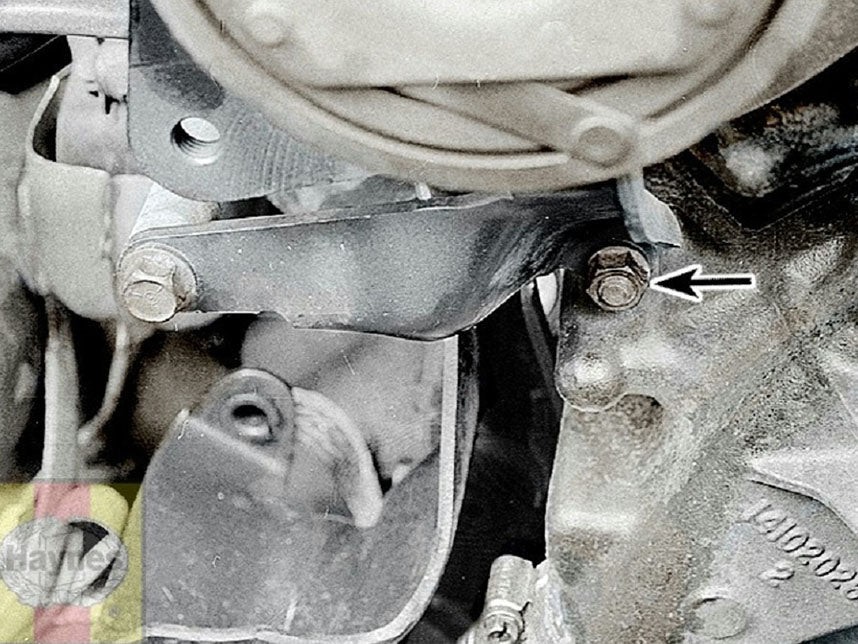

While this image illustrates accessory bracket removal, understanding component locations is key to accessing fuses.

Identifying the OBD2 Fuse

Using the fuse box diagram, look for labels that might indicate “OBD,” “OBDII,” ” диагностический разъем (Diagnostic Connector),” “Data Link Connector (DLC),” or something similar. Fuse box layouts can vary slightly, but these are common labels associated with the OBD2 system.

- Fuse Rating: Once you’ve located a potential candidate, check the fuse rating (the number printed on the fuse itself, e.g., 10, 15, 20). The correct rating is important for proper circuit protection. The diagram should also specify the correct amperage.

- Visual Inspection: Before removing the fuse, visually inspect it. A blown fuse often has a broken wire inside or a darkened or melted appearance.

Similar to identifying water pump bolts, a systematic approach is needed to locate the correct fuse within the fuse box.

Symptoms of a Blown OBD2 Fuse

If the OBD2 fuse is blown, you might experience several symptoms:

- OBD2 Scanner Not Connecting: This is the most common symptom. If your OBD2 scanner or code reader fails to power up or connect to the vehicle’s computer, a blown fuse is a prime suspect.

- Check Engine Light Issues: In some cases, a blown OBD2 fuse can indirectly affect the check engine light system, although this is less direct.

- Other Electrical Issues: Depending on the specific circuit design, a blown OBD2 fuse might be related to other minor electrical issues, although this is less common and varies by vehicle.

Troubleshooting and Replacing the OBD2 Fuse

If you suspect a blown OBD2 fuse, follow these steps to troubleshoot and replace it:

- Turn Off the Ignition: Ensure the vehicle’s ignition is completely turned off before working with fuses.

- Remove the Fuse: Use a fuse puller (often found in the fuse box or your vehicle’s toolkit) or needle-nose pliers to gently remove the suspected OBD2 fuse.

- Inspect the Fuse: Examine the fuse closely for any signs of being blown (broken wire, melted plastic).

- Test with a New Fuse: Replace the blown fuse with a new fuse of the exact same rating. Never use a fuse with a higher amperage rating, as this can damage the electrical system.

- Test the OBD2 Port: Try connecting your OBD2 scanner again to see if it now powers up and connects.

- Address Underlying Issues: If the fuse blows again immediately, there’s likely an underlying electrical problem in the OBD2 circuit. This could be a short circuit in the wiring, a faulty OBD2 port, or an issue with a component connected to the OBD2 system. Further diagnosis by a qualified mechanic may be necessary to pinpoint and repair the root cause.

Just as gently rocking a water pump helps removal, carefully handle fuses to avoid damage during inspection and replacement.

Importance of Correct Fuse Rating

Using the correct fuse rating is critical for safety and proper electrical system operation. A fuse with a higher amperage rating than specified will not provide adequate protection, potentially leading to damage to wiring and components, or even fire hazards in severe cases. Always replace a blown fuse with one of the exact same type and amperage rating as specified in your vehicle’s owner’s manual or fuse box diagram.

Conclusion

Troubleshooting a non-functioning OBD2 port in your 1998 GMC 2500 Classic often starts with checking the OBD2 fuse. By understanding its location, function, and how to identify a blown fuse, you can often resolve simple diagnostic communication issues yourself. However, remember that repeated fuse failures indicate a more serious underlying electrical problem that requires professional attention. Always prioritize safety and proper component ratings when working with your vehicle’s electrical system.