Like many Jeep Wrangler owners, encountering a check engine light can be a moment of concern. Recently, while driving my 1998 Jeep Wrangler TJ, that familiar orange glow appeared on the dashboard. No noticeable performance issues, but the light was definitely there to stay. For those of us who like to get hands-on with our Jeeps, this often means it’s time to investigate ourselves. And for a 1998 Jeep Wrangler, OBD2 is your best friend in these situations.

Understanding and utilizing the OBD2 system in your 1998 Jeep Wrangler can save you time, money, and unnecessary trips to the mechanic. In my case, facing a persistent check engine light in my ’98 TJ prompted me to finally delve into the world of OBD2 diagnostics. Having already installed a Panasonic Toughbook in my Jeep last fall, I realized I had the perfect platform for an OBD2 scanner interface. It was time to equip my toolbox with modern diagnostic capabilities for my trusty Wrangler.

Why OBD2 for a 1998 Jeep Wrangler?

OBD2, or On-Board Diagnostics II, became a standard in vehicles sold in the United States starting in 1996. This system is designed to monitor various aspects of your vehicle’s engine and emissions systems. When something goes wrong, like a sensor malfunction or an emissions issue, the system logs a diagnostic trouble code (DTC) and often illuminates the check engine light. For a 1998 Jeep Wrangler, which falls squarely within the OBD2 era, this diagnostic system is invaluable.

Before OBD2, diagnosing car problems often required specialized tools and a deeper understanding of vehicle mechanics. OBD2 standardized the diagnostic process, making it more accessible for both mechanics and DIY enthusiasts. For owners of a 1998 Jeep Wrangler, an OBD2 scanner is an essential tool for troubleshooting issues, maintaining your vehicle, and understanding its health.

Choosing the Right OBD2 Scanner for Your ’98 Wrangler

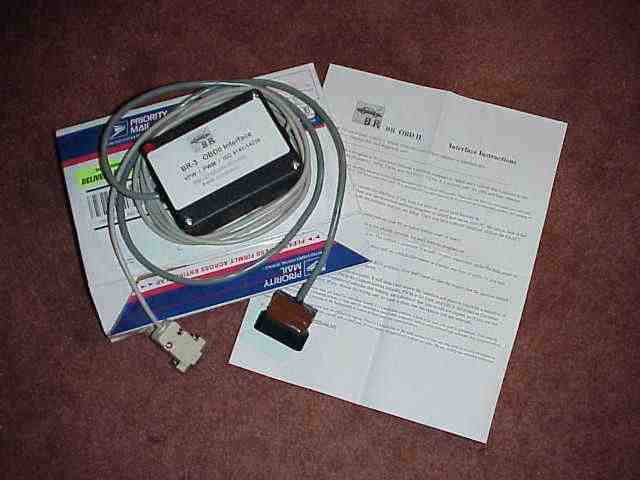

The market offers a wide array of OBD2 scanners, from basic code readers to advanced professional-grade tools. For a 1998 Jeep Wrangler, a mid-range scanner or even a basic interface for your laptop can be incredibly effective. In my search for an OBD2 interface, I explored various options online and decided on the BR-3 interface from obddiagnostics.com.

This particular interface appealed to me because it connected to my laptop via a serial cable, and software was available for Windows, DOS, and even Linux. The price was reasonable, and it seemed like a solid option for diagnosing my ’98 TJ. Whether you choose a dedicated handheld scanner or a PC-based interface, ensure it supports the OBDII protocols relevant to your Jeep, which includes ISO9141 for Chrysler vehicles like the Wrangler.

Connecting and Reading Codes on Your 1998 Jeep Wrangler

The OBD2 port on a 1998 Jeep Wrangler TJ is conveniently located beneath the dashboard on the driver’s side, near the steering column. Specifically, it’s in the vicinity of your left knee. Connecting your OBD2 scanner is usually a straightforward process.

- Locate the OBD2 Port: Look under the dash on the driver’s side of your 1998 Jeep Wrangler.

- Connect the Scanner: Plug your OBD2 scanner into the port. Ensure it’s firmly connected.

- Turn Ignition to “On”: Turn your Jeep Wrangler’s ignition to the “ON” position, but do not start the engine unless your scanner instructions specify otherwise.

- Power On Scanner/Software: Turn on your handheld scanner or launch the OBD2 software on your laptop.

- Read Diagnostic Codes: Follow your scanner’s instructions to read the diagnostic trouble codes (DTCs).

Once connected, my BR-3 interface and software allowed me to easily navigate through menus and access diagnostic information. For a 1998 Jeep Wrangler, you’ll typically select the ISO9141 protocol in your software. From there, you can retrieve trouble codes and view live data from various engine sensors.

Diagnosing the Check Engine Light: An O2 Sensor Issue

Using the OBD2 scanner on my 1998 Jeep Wrangler, I was able to quickly pull the trouble codes. With the help of my Jeep Wrangler Factory Service Manual (FSM) and some online research, I narrowed down the issue to the downstream O2 sensor. The data from the OBD2 scanner indicated a flat line reading from the downstream sensor, whereas the upstream sensor was showing the expected sine wave pattern.

According to my FSM, the downstream O2 sensor should display a similar pattern to the upstream sensor but with less fluctuation, assuming the catalytic converter is functioning correctly. The flat line reading strongly suggested a problem with the sensor itself or its wiring. The OBD2 scanner provided concrete data, moving beyond guesswork and pointing directly to a potential area of concern.

The Unexpected Fix: A Wire Break, Not the Sensor

Prepared to replace the downstream O2 sensor, I decided to take one last look before heading to the auto parts store. Upon closer inspection under the Jeep, I discovered a small, shiny copper spot on the O2 sensor wiring harness. It turned out the rotating rear output yoke of the transfer case had barely made contact with the sensor’s wiring pigtail.

The contact was minimal, but enough to nick the wire and create a break in the copper core, even though the insulation was still mostly intact. A quick repair with a soldering iron and heat shrink tubing fixed the broken wire. After reconnecting everything and clearing the codes with the OBD2 scanner, the check engine light vanished, and the downstream O2 sensor readings returned to normal.

This experience highlighted the power of OBD2 diagnostics for a 1998 Jeep Wrangler. While the initial diagnosis pointed towards the O2 sensor, the scanner provided the crucial information needed to investigate further and ultimately uncover a simple wiring issue. Without the OBD2 scanner, troubleshooting this problem could have been far more time-consuming and potentially led to unnecessary parts replacements.

Conclusion: OBD2 – A Must-Have for 1998 Jeep Wrangler Owners

Investing in an OBD2 scanner for your 1998 Jeep Wrangler is a smart move for any owner who likes to understand and maintain their vehicle. It empowers you to read trouble codes, monitor engine parameters in real-time, and gain valuable insights into your Jeep’s health. While auto parts stores can read codes for you, having your own OBD2 scanner provides immediate access to diagnostic information whenever that check engine light appears.

Whether you’re tackling a check engine light or performing routine maintenance on your 1998 Jeep Wrangler, an OBD2 scanner is an invaluable tool that can save you time, money, and keep your TJ running smoothly for years to come.