Despite their prevalence in modern vehicles for over a decade, Air/Fuel Ratio (AFR) sensors, also known as wideband oxygen sensors, can still seem enigmatic to many in the automotive repair field. The complexity of their data PIDs, their non-switching behavior compared to traditional O2 sensors, and the presence of up to seven wires often deter technicians. However, understanding these sensors is crucial for accurate diagnostics and ensuring optimal engine performance, especially in vehicles like the Honda Civic.

This guide aims to demystify the intricacies of Civic OBD2 air fuel ratio sensor wiring and diagnostics. Whether you’re a seasoned mechanic or a DIY enthusiast, this article provides a comprehensive overview of wideband sensors, focusing specifically on Honda Civic applications. We’ll delve into the wiring configurations, scan data interpretation, and troubleshooting techniques essential for maintaining your Civic’s engine health and efficiency. While this article provides valuable insights, for a deeper dive into the internal construction and advanced testing of wideband sensors, resources from experts like ScannerDanner and wbo2.com are highly recommended.

scannerdanner.com/forum/diagnostic-tools…sor-diagnostics.html

Key Principles of Wideband Air/Fuel Ratio Sensors

Before diving into the specifics of Civic Obd2 Air Fuel Ratio Wiring, let’s establish some fundamental concepts that apply across various makes and models, including the Honda Civic.

1. Equivalence Ratio and Lambda: Universal Measures

OEMs may differ significantly in how they present air/fuel ratio sensor signals. Some use current-based readings, while others interpret them as voltage. This variation can be confusing when diagnosing different vehicle brands.

To simplify interpretation, remember the Equivalence Ratio or Lambda PIDs. Equivalence Ratio is commonly found in Global OBD-II data and manufacturer-specific lists, while Lambda is frequently used in Honda diagnostics. Both metrics provide a standardized representation of the air-fuel mixture. A value of 1.00 indicates stoichiometric combustion (the ideal air-fuel mixture), values above 1.00 signify a lean mixture (excess air), and values below 1.00 indicate a rich mixture (excess fuel). Understanding Equivalence Ratio or Lambda allows for effective diagnosis even without in-depth knowledge of specific wideband sensor signals.

2. The Non-Negotiable Heater Circuit

Unlike traditional oxygen sensors, where a faulty heater element might still allow for signal generation under hot exhaust conditions, wideband sensors require a functioning heater. If the heater circuit malfunctions, the sensor will not operate correctly, and in some cases, vehicles, including Honda Civics, will revert to open-loop fuel control, compromising fuel efficiency and emissions. Therefore, checking the heater circuit is a critical first step in diagnosing any potential Civic OBD2 air fuel ratio sensor issue.

3. Rationality Testing: Comparing Upstream and Downstream Sensors

A valuable diagnostic technique involves comparing the signals of upstream and downstream oxygen sensors on the same bank. This method, championed by experts like Paul Danner, helps determine if a sensor is providing inaccurate readings. This principle remains valid for wideband sensors. If you suspect a Civic air fuel ratio sensor is stuck in a rich or lean state, compare its reading to the downstream sensor. Discrepancies can indicate a faulty sensor or wiring issue.

4. Trim Resistors and Wiring Configurations

Throughout this discussion, we’ll reference sensor designs by the number of wires on the harness side – four, six, or seven wires. It’s important to note that six and seven-wire designs typically have only five wires on the sensor side itself. This difference is due to trim resistors, also known as resistor chips.

Image alt text: Close-up of a trim resistor chip component, illustrating its small size and electrical contacts.

Image alt text: Example of a trim resistor chip integrated into a sensor connector, highlighting its position relative to wiring terminals.

Image alt text: Diagram showing the placement of a trim resistor within a sensor wiring harness, indicating its role in circuit calibration.

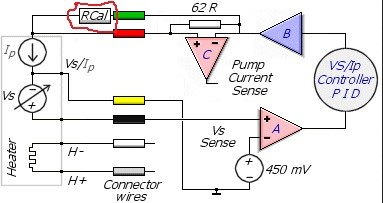

The trim resistor is an integral part of the wideband sensor connector, not the sensor itself. Installed at the factory, it allows the Powertrain Control Module (PCM) to compensate for manufacturing variations in sensor production. The PCM measures this resistance on a dedicated circuit, which can be parallel to the heater power or the sensor signal circuit. Honda, in their seven-wire designs, even dedicates two wires solely to the resistor circuit.

While the impact of trim resistor failures on fuel control is not definitively documented, their presence highlights the complexity of wideband sensor systems and the importance of considering all wiring elements when diagnosing issues with Civic OBD2 air fuel ratio wiring.

Honda Civic OBD2 Air Fuel Ratio Sensor Specifics

Honda Civics primarily utilize four-wire wideband sensors in their four-cylinder engines. The V6 models often employ seven-wire sensors, which are beyond the scope of this focused guide on Civic OBD2 air fuel ratio wiring but share similar diagnostic principles.

Honda Civic Four-Wire Sensor: Scan Data Interpretation

Honda typically displays the air fuel ratio sensor signal as a direct current reading, avoiding voltage conversions. In scan data, 0 mA represents stoichiometric, negative current values indicate a lean mixture, and positive current values indicate a rich mixture.

Image alt text: Honda Civic scan data display showing air fuel ratio sensor current in milliamperes (mA), alongside AF Feedback and AF Feedback Average PIDs for fuel trim analysis.

Analyzing Honda scan data, you’ll observe current values around 0.4 mA during power enrichment (richer mixture for performance) and up to 1.5 mA during fuel cut deceleration (leaner mixture when coasting). These small current values emphasize the precision required in measuring the sensor signal directly.

Honda’s AF FB (Air Fuel Feedback) and AF FB AVE (Air Fuel Feedback Average) PIDs are Honda-specific terms for short-term and long-term fuel trims, respectively. While some scan tools like Snap-On translate these terms, not all scanners do. Remember that values above 1.00 indicate positive fuel trims (adding fuel), and values below 1.00 represent negative fuel trims (reducing fuel). For instance, AF FB at 1.13 and AF FB AVE at 0.98 would translate to a short-term fuel trim of +13% and a long-term fuel trim of -2%. Understanding these PIDs is crucial for assessing fuel system adjustments based on the Civic air fuel ratio sensor readings.

Honda Civic Four-Wire Sensor: Wiring Checks

The wiring checks for Honda Civic four-wire wideband sensors are straightforward and share similarities with Toyota sensors. Honda utilizes a Bosch-style sensor-side wiring color format.

Image alt text: Honda Civic air fuel ratio sensor wiring diagram for a four-wire sensor, illustrating wire colors, pin assignments (AFS+, AFS-, Heater +, Heater -), and expected voltage readings.

Honda Civic OBD2 Air Fuel Ratio Wiring Test Procedure:

-

Sensor Circuit Voltage Check: With the sensor plugged in or disconnected, you should measure approximately 2.2V on the AFS+ wire and 1.8-1.9V on the AFS- wire at the harness connector. These voltages are supplied by the PCM and should remain relatively stable regardless of mixture changes. If these voltages are present, the sensor circuit wiring is likely intact.

-

Heater Circuit Check: Verify 12V power supply to one of the heater wires (Heater +). The other heater wire (Heater -) is controlled by the PCM as a computer-controlled ground. Check for proper ground switching by the PCM.

Like Toyota four-wire sensors, this design simplifies quick circuit integrity verification, even without immediate access to a wiring diagram. The consistent voltage readings on the sensor circuit wires provide a reliable baseline for diagnosing wiring issues related to the Civic OBD2 air fuel ratio sensor.

General Diagnostic Approach for Civic OBD2 Air Fuel Ratio Wiring Issues

When troubleshooting potential problems with your Civic’s air fuel ratio sensor, consider these steps:

-

Scan for Diagnostic Trouble Codes (DTCs): Use an OBD2 scanner to check for any stored DTCs related to the air fuel ratio sensor or heater circuit. DTCs can provide valuable clues about the nature and location of the fault.

-

Inspect Wiring and Connectors: Visually inspect the sensor wiring harness and connector for any signs of damage, corrosion, or loose connections. Pay close attention to the wiring near the exhaust components, where heat and vibration can cause wear and tear.

-

Perform Wiring Checks: Utilize a multimeter to perform the voltage and continuity checks outlined above for the Honda Civic four-wire sensor. Verify the presence of reference voltages, heater circuit continuity, and proper ground switching by the PCM.

-

Analyze Scan Data: Examine live scan data PIDs for the air fuel ratio sensor, fuel trims (AF FB, AF FB AVE), and related parameters. Assess the sensor readings for rationality, compare upstream and downstream sensor data if applicable, and evaluate fuel trim adjustments for indications of underlying issues.

-

Consider Sensor Replacement (if necessary): If wiring and circuit checks are satisfactory, and scan data suggests a faulty sensor, consider replacing the air fuel ratio sensor. Always use a high-quality replacement sensor that meets or exceeds OEM specifications for your Honda Civic.

Conclusion

Understanding Civic OBD2 air fuel ratio wiring and sensor diagnostics is essential for maintaining optimal engine performance, fuel efficiency, and emissions control. By grasping the fundamental principles of wideband sensors, interpreting Honda-specific scan data, and performing systematic wiring checks, you can effectively troubleshoot and resolve issues related to your Civic’s air fuel ratio sensor system. Remember to consult repair manuals and online resources for specific wiring diagrams and procedures relevant to your Honda Civic model year and engine configuration. Proper diagnosis and repair ensure your Civic continues to run smoothly and efficiently for years to come.