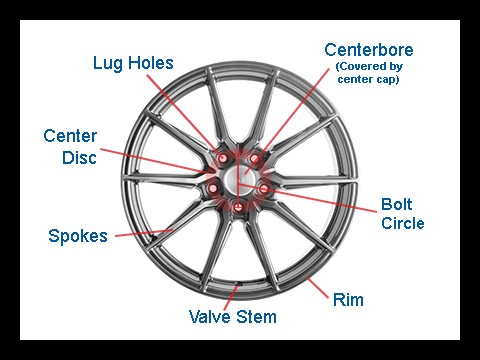

Understanding the anatomy of your car’s wheels is crucial for maintenance, repair, and even upgrading for performance or aesthetics. When we talk about wheels, often the term “rims” comes up, but what exactly are Car Rim Parts? This guide breaks down the essential components of a car wheel, focusing on the hub, spokes, and the rim itself, to give you a comprehensive understanding.

The Hub: The Wheel’s Centerpiece

The hub is the central part of the wheel, and it’s responsible for connecting the wheel to the vehicle’s axle. It’s a critical component that bears the vehicle’s weight and ensures the wheel rotates smoothly. Let’s delve into the key parts of the hub:

-

Centerbore: This is the large hole at the very center of the wheel. Its primary function is to fit directly onto the axle hub assembly of your car. The centerbore is load-bearing, meaning it helps distribute the weight of the vehicle. It’s vital that the centerbore is at least as large as the axle mount. If it’s larger, which is often the case with aftermarket wheels designed to fit various vehicles, then hub-centric rings (or hub rings) are used. These rings fill the gap between the wheel’s centerbore and the axle mount, ensuring the wheel is perfectly centered, minimizing vibration and stress on the lug studs.

-

Center Disc (or Plate): Surrounding the centerbore is the center disc. This cylindrical section is where the lug holes are located and acts as the meeting point for the spokes. The center disc is a force-receiver, handling loads from the axle and the braking system. The back surface of the center disc, known as the mounting pad, is designed to sit flush against the axle seat, providing a secure and stable connection.

-

Lug Holes: These are the precisely drilled holes around the centerbore, essential for attaching the wheel to the car’s axle. On most vehicles, these holes align with threaded studs that protrude from the axle seat. Lug nuts are then tightened onto these studs to clamp the wheel securely. Interestingly, some manufacturers, particularly German brands, often utilize wheel bolts instead of studs and lug nuts. Wheel bolts thread directly into the hub assembly.

-

Bolt Circle (or Bolt Pattern): The bolt circle is a measurement that describes the configuration of the lug holes. It’s defined as the diameter of the circle that passes through the center of each lug hole. Bolt patterns are expressed by the number of lugs and the bolt circle diameter (e.g., 5×114.3mm means 5 lugs on a 114.3mm diameter circle). Understanding your vehicle’s bolt pattern is crucial when selecting new wheels to ensure compatibility.

-

Center Cap: A center cap is a removable cover that snaps or screws into the centerbore on the outward-facing side of the wheel. Originally designed to simply conceal the centerbore, modern center caps often serve a dual purpose: aesthetic enhancement and protection for the lug nuts or wheel bolts from road debris and corrosion.

Spokes: The Structural and Style Element

Spokes are the structural arms that extend outward from the hub and connect to the rim. They are the backbone of the wheel, providing the necessary strength and rigidity to support the vehicle’s weight and withstand driving forces. Beyond their structural role, spokes are also a major design element, significantly contributing to a wheel’s visual appeal.

Custom wheel designs offer a vast array of spoke styles, varying in number, thickness, shape, and pattern. From classic straight spokes to intricate mesh designs, the possibilities are extensive. While most car wheels feature spokes, some heavy-duty truck or trailer wheels might have solid faces, essentially eliminating spokes altogether for maximum strength in demanding applications.

A common design is the five-spoke wheel, favored for its engineering advantages. In a five-spoke design, each spoke is effectively supported by two opposing spokes, which helps to dampen torsional vibrations and distribute stress evenly across the wheel structure. While a lower spoke count can contribute to a slightly lighter wheel, in most passenger car applications, the number of spokes has a minimal impact on overall weight or performance compared to factors like wheel material and manufacturing processes. Therefore, when choosing wheels, personal style and aesthetic preference often take precedence alongside structural considerations.

Rim: The Tire’s Foundation

The rim, sometimes referred to as the barrel, is the outer cylindrical edge of the wheel. It’s the part that directly supports the tire, giving the wheel its overall shape and forming the airtight seal necessary for tubeless tires. While “rim” is often used informally to mean the entire wheel, technically, it’s just this outer component. Let’s examine the key features of the rim:

-

Outer Lip: This is the outermost edge of the rim, extending from the wheel’s face to the very edge. The depth of the outer lip is a styling characteristic. A deep lip can enhance the visual appeal, especially on wider wheels, but it’s also more susceptible to damage from curb rash or impacts because the spokes are set further inward, offering less direct support to the lip itself. On multi-piece wheels, particularly three-piece designs, the outer lip is often manufactured as a separate component, allowing for customization and easier replacement if damaged.

-

Flanges: Flanges are the flared edges located on both the inboard and outboard sides of the rim. Their primary function is to retain the tire on the wheel. These flared edges are crucial in preventing the tire beads from slipping off the rim, particularly during cornering or underinflated conditions, ensuring tire security and driver safety.

-

Bead Rests: Bead rests are specific areas on the rim’s outer surface where the tire beads make contact and seat against the wheel. These surfaces are critical for creating an airtight seal between the tire and the wheel. Before mounting a new tire, it’s recommended to clean the bead rests thoroughly to remove any dirt, corrosion, or debris that could compromise the seal and lead to air leaks.

-

Mounting Humps (or Safety Humps): Mounting humps are small, circumferential ridges located just inboard of the bead rests. These seemingly minor features play a vital role in tire retention. They provide an extra measure of security by preventing the tire beads from slipping inward into the drop center of the rim, especially when encountering sudden impacts or cornering forces. These humps are essential for modern tubeless tire systems, enhancing safety and performance.

-

Drop Center: The drop center is the narrowest section of the rim’s barrel, running circumferentially around the wheel. Its purpose is to facilitate tire mounting and demounting. This reduced diameter section allows the tire beads to be pushed into the center, providing enough slack to stretch the opposite bead over the rim flange without excessively stressing or damaging the tire bead wires during installation or removal.

-

Valve Stem Hole: Every rim incorporates a precisely located hole designed to accommodate the valve stem. The valve stem is a crucial component – it’s a small, typically metal, air valve that allows you to inflate or deflate the tire and to check and maintain the tire’s air pressure. The valve stem ensures an airtight seal, preventing air leakage from the inflated tire.