Being a car owner in the UK comes with responsibilities, and a big part of that is proactive car maintenance. It can feel overwhelming trying to understand all the mechanical parts of cars, but having this knowledge is crucial for making informed decisions when repairs are needed. Knowing the basics of your vehicle’s anatomy empowers you to keep it running smoothly and safely on UK roads.

One thing is certain: knowing which car parts are critical and potentially dangerous if they malfunction, versus those that are less critical and perhaps more affordable to maintain, is invaluable. This guide will walk you through the key mechanical parts of cars commonly found in the UK, helping you understand their function and importance.

Understanding the different parts of your car is essential for UK drivers to ensure proper maintenance and manage car ownership costs effectively.

Let’s explore the inner workings of a car, from the engine’s pistons and spark plugs to the braking system and exhaust, and gain a clear understanding of the essential components that make up the anatomy of your vehicle, tailored for the UK context.

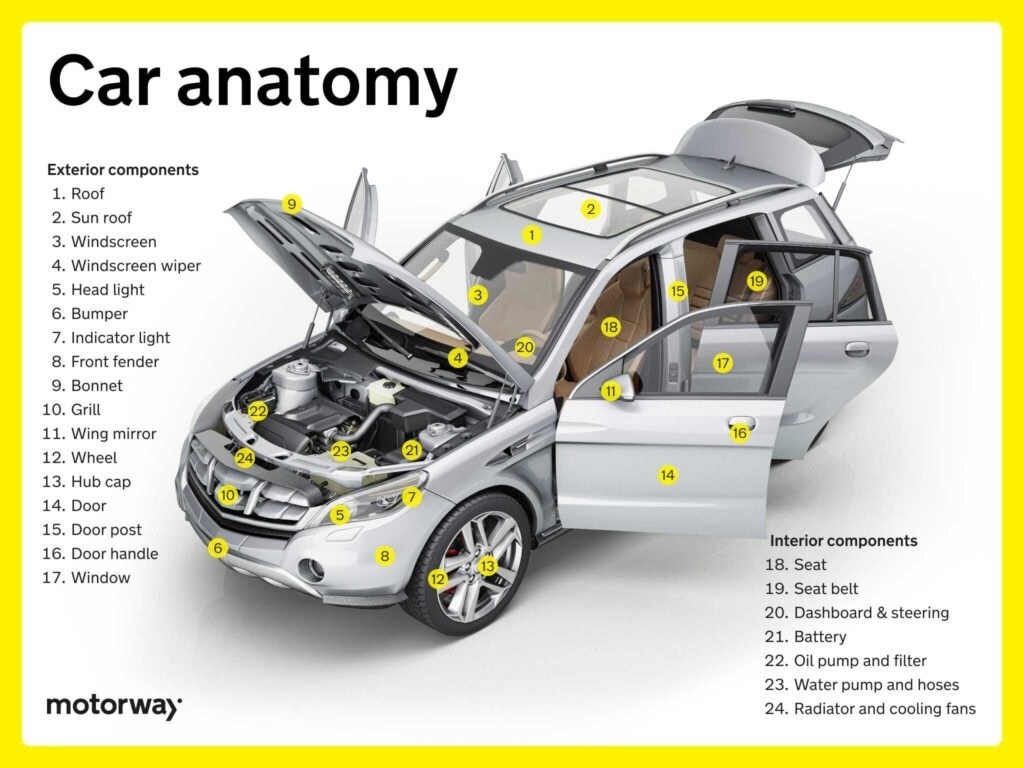

Engine Components

Maintaining your car’s engine is paramount in the UK to preserve its value, ensure reliability, and keep your running costs economical.

Cylinder Block and Pistons

At the heart of your car, the engine’s cylinder block serves as the robust foundation of the powerhouse. Within this block are individual cylinders, precisely engineered hollow tubes where the controlled combustion process takes place. These cylinders are the core of where the energy to power your vehicle is generated.

Moving within these cylinders are pistons, secured with piston rings. These pistons move in a continuous up-and-down motion. Their primary function is to convert the explosive energy from fuel combustion into mechanical, driving force. This force is what ultimately propels your car forward. The precise interaction between the pistons and cylinders is fundamental, making it the primary source of power in any internal combustion engine vehicle on UK roads.

Crankshaft and Camshaft

Deep within the engine’s complex mechanism, you’ll find the crankshaft and camshaft working in perfect harmony. The crankshaft is a rotating axle that converts the linear, up-and-down motion of the pistons into rotational energy. This rotational energy is the driving force that powers your wheels and moves your car.

In sync with the crankshaft, the camshaft manages the critical timing of the engine’s valves. These valves control the intake of air and fuel and the expulsion of exhaust gases. The camshaft ensures these valves open and close at precisely the right moments for optimal combustion. Together, the crankshaft and camshaft synchronize the internal combustion events with meticulous movements, contributing to the smooth and propulsive motion that you experience while driving in the UK.

Intake and Exhaust Manifolds

Think of the intake and exhaust manifolds as the lungs of your car’s engine, responsible for managing airflow for the combustion process. The intake manifold draws fresh air into the engine, providing the oxygen needed for fuel combustion within the cylinders. This clean air intake is crucial for efficient engine operation.

Conversely, the exhaust manifold is responsible for expelling spent gases after combustion. It collects these gases and directs them away from the engine, channeling them through the exhaust system. Working together, the intake and exhaust manifolds optimize your car’s internal combustion engine performance, ensuring a balanced combination of power and fuel efficiency, essential for UK driving conditions. It’s important to note that electric vehicles, increasingly popular in the UK, do not have intake and exhaust manifolds as they operate without internal combustion engines.

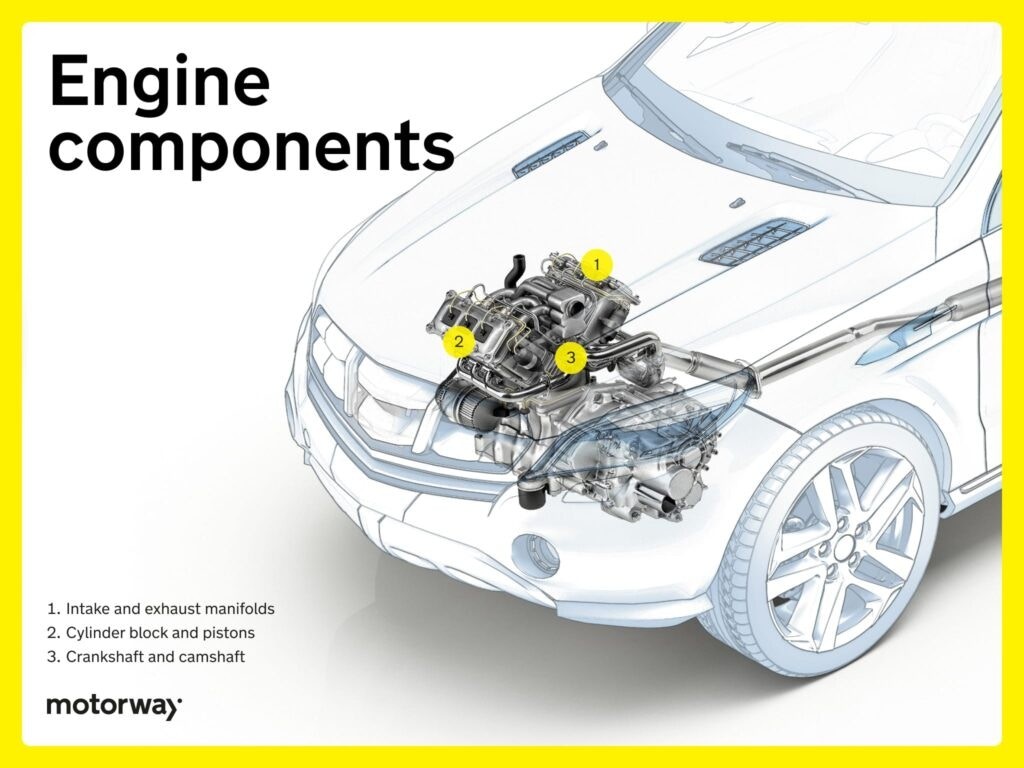

Powertrain and Gearboxes

For cars with manual transmissions, the gearbox is a vital component that requires smooth operation and careful maintenance for optimal performance on UK roads.

Different Types of Gearboxes, Otherwise Known as Transmission

The gearbox, or transmission, is a critical part of your car’s powertrain, responsible for transferring power from the engine to the wheels. Different types of gearboxes offer varying driving experiences and levels of driver involvement.

Manual Gearboxes

Manual gearboxes are designed to give the driver complete control over gear selection. This type of transmission requires the driver to manually engage and disengage gears using a clutch pedal and gear stick. Manual gearboxes allow drivers to actively respond to changing driving conditions, such as varying road surfaces, acceleration needs, and deceleration, offering a more engaged driving experience favoured by some UK drivers.

Automatic Gearboxes

Automatic gearboxes are engineered to simplify driving by automatically shifting gears. This seamless gear changing happens without any driver intervention, eliminating the need to operate a clutch or manually shift gears. Automatic transmissions use a torque converter, a type of fluid coupling, to ensure smooth gear changes and power delivery, providing a more relaxed driving experience, particularly appreciated in busy UK traffic.

CVTs

Continuously Variable Transmissions (CVTs) represent a more advanced approach to gearbox mechanics. CVTs utilize a system of pulleys and belts to provide an almost infinite range of gear ratios. This design results in exceptionally smooth and continuous acceleration, without the stepped gear changes of traditional automatic or manual transmissions. CVTs are designed to optimize fuel efficiency and dynamically adapt to changing driving conditions, making them an increasingly popular choice in modern vehicles in the UK for their performance and economy.

Differential and Driveshaft

Within your car’s power system, the differential and driveshaft work in conjunction to deliver power to the wheels, but each handles a distinct role. The driveshaft is the component that transmits the rotational power generated by the engine and gearbox to the wheels. It acts as the conduit for power delivery.

The differential, on the other hand, is responsible for distributing power evenly to the wheels, especially when turning. It allows the wheels to rotate at different speeds, which is essential when cornering to prevent wheel slippage and maintain smooth handling. Together, the driveshaft and differential create a harmonious system that enables your car to move effectively and efficiently, whether driving straight or navigating corners on UK roads.

Clutch and Torque Converter

The clutch and torque converter are key components in the realm of gears and transmission, each playing a vital role in how power is managed and delivered. In cars equipped with manual transmissions, the clutch allows the driver to engage and disengage the engine from the gearbox. This precise control is necessary for smooth gear changes and starting and stopping the vehicle.

In contrast, automatic transmissions utilize a torque converter. This fluid coupling smoothly transfers power from the engine to the transmission without a direct mechanical link. The torque converter ensures seamless gear shifts and smooth power delivery, contributing to the comfortable and dynamic driving experience associated with automatic cars, a popular choice for many UK motorists.

Fuel and Ignition Systems

A properly functioning fuel system is absolutely critical in internal combustion engine cars in the UK to ensure reliable performance and avoid dangerous breakdowns.

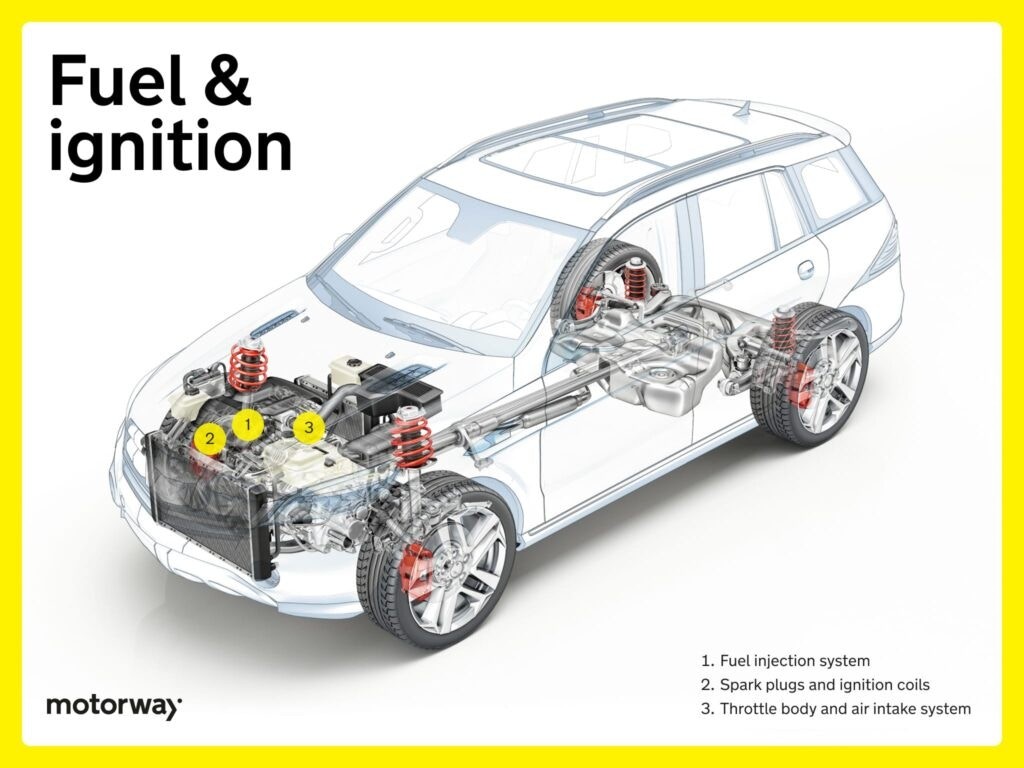

Fuel Injection System

The fuel injection system is a critical component in modern engines, playing a key role in ensuring optimal combustion and engine efficiency. Fuel injectors are precision devices that deliver fuel directly into the engine cylinders in a highly controlled manner. This precise fuel delivery enhances engine power, improves fuel efficiency, and reduces emissions, contributing to better performance and environmental responsibility on UK roads.

Fuel injection systems have largely replaced carburettors, an older technology known for being prone to breakdowns due to clogging and wear. Fuel injectors offer superior fuel distribution, resulting in enhanced engine performance and reduced harmful emissions, making them a standard feature in most modern cars in the UK.

Spark Plugs and Ignition Coils

The ignition system in a petrol engine is composed of spark plugs and ignition coils, working in tandem to initiate the combustion process. Spark plugs are responsible for generating the spark that ignites the air-fuel mixture within the engine cylinders. Ignition coils play a crucial role in amplifying the voltage from the car’s electrical system to a level high enough to create a spark at the spark plug gap.

The synchronized operation of spark plugs and ignition coils is essential for efficient and rapid ignition. This precise ignition timing is critical for optimal engine performance, responsiveness, and fuel efficiency. Well-maintained spark plugs and ignition coils are vital for a reliable and economical driving experience in the UK.

Throttle Body and Air Intake System

The throttle body and air intake system work together to regulate the amount of air that flows into the engine. The throttle body acts as a valve that controls the volume of air entering the engine’s intake manifold. The position of the throttle valve, controlled by the accelerator pedal, dictates how much air is allowed to pass through.

The air intake system is designed to ensure a clean and efficient supply of air to the engine. It typically includes an air filter to remove dust, dirt, and other contaminants from the incoming air. By working in concert, the throttle body and air intake system manage the engine’s “breathing,” which is crucial for achieving peak engine power, optimal fuel efficiency, and overall engine performance, tailored to the demands of UK driving conditions.

Cooling and Lubrication

Radiator and Cooling Fans

The radiator and cooling fans are primary components in protecting internal combustion engines from overheating, a critical concern, especially during warmer UK summers or in stop-start traffic. The radiator’s function is to dissipate heat from the engine coolant. Hot coolant from the engine circulates through the radiator, where heat is transferred to the outside air.

Cooling fans enhance this heat dissipation process by increasing airflow across the radiator. These fans are often automatically activated when the engine temperature rises, ensuring sufficient cooling, particularly when the car is stationary or moving slowly. Together, the radiator and cooling fans maintain the engine at an optimal operating temperature, preventing damage from overheating and promoting efficient engine performance and longevity, vital for reliable motoring in the UK.

Water Pump and Hoses

The water pump and hoses are additional crucial components in the engine’s cooling system, working alongside the radiator and fans to regulate engine temperature. The water pump is responsible for circulating coolant throughout the engine and cooling system. It pushes coolant through the engine block, cylinder head, and radiator, ensuring continuous heat removal.

Hoses act as conduits, allowing the coolant to flow between different components of the cooling system. They connect the water pump to the engine, radiator, and other parts, creating a closed loop for coolant circulation. These components work together to maintain a stable engine temperature, preventing overheating and ensuring reliable engine operation, essential for avoiding breakdowns on UK roads.

EV Battery Cooler System

Electric Vehicles (EVs), increasingly common in the UK, employ different cooling systems compared to traditional combustion engine cars. EV cooling systems are specifically designed to manage the temperature of the battery pack and electric motor, rather than an internal combustion engine. The battery cooler, which functions similarly to a traditional radiator, dissipates heat from the battery coolant. Coolant circulates through the battery pack, absorbing heat generated during battery operation, and then flows to the cooler to release this heat.

The cooling system in EVs also includes fans to enhance airflow and further aid in heat dissipation, particularly important during rapid charging or heavy use. Maintaining an optimal temperature for the battery and electric motor is crucial in EVs for maximizing battery life, ensuring efficient operation, and maintaining performance. Effective thermal management is a key aspect of EV technology and reliability in the UK climate.

Oil Pump and Oil Filter

The oil pump and oil filter are essential components of the engine’s lubrication system, critical for minimizing friction and wear within the engine. The oil pump circulates engine oil throughout the engine, ensuring that vital moving parts like pistons, bearings, and camshafts are continuously lubricated. This lubrication reduces friction between these components, preventing wear and tear and allowing for smooth engine operation.

The oil filter works in conjunction with the oil pump to maintain the cleanliness of the engine oil. It removes impurities, contaminants, and debris from the oil as it circulates. By filtering out these particles, the oil filter prevents them from causing damage to engine components and ensures that clean, effective lubrication is maintained. Together, the oil pump and oil filter extend engine life and maintain optimal engine performance, contributing to the reliability and longevity of vehicles in the UK.

Electrical System

The electrical system is central to the operation of almost every aspect of your car, from starting the engine to powering accessories, making it a crucial system to maintain in UK vehicles.

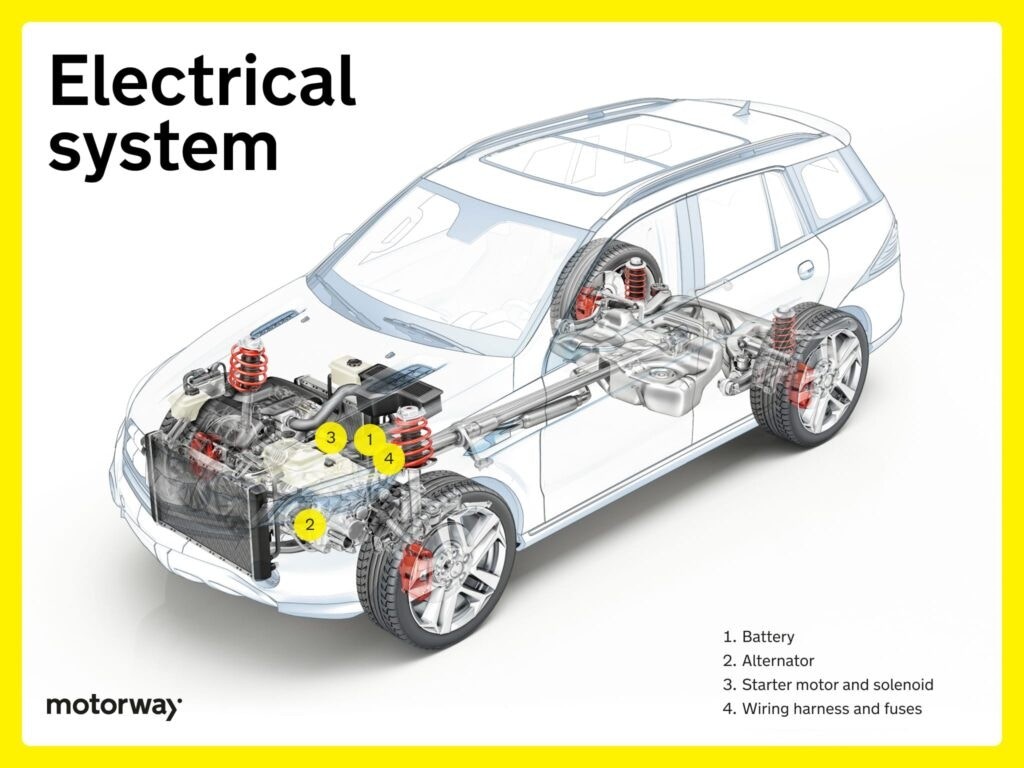

Battery

The car battery serves as the primary source of electrical energy for your vehicle, acting as the initial power reservoir. It provides the necessary electrical current to start the engine and powers all electrical functions when the engine is not running. Importantly, all cars, including both internal combustion engine vehicles and EVs, rely on a 12V battery for their electrical systems.

If a car battery develops a fault or loses its charge capacity, it will need to be replaced. Battery maintenance, particularly during colder UK months, is important to ensure reliable starting and electrical system operation. A healthy battery is fundamental to the dependable functioning of any car’s electrical system.

Alternator

The alternator is a vital component in a car’s electrical system, responsible for generating electrical power while the engine is running. It converts mechanical energy from the engine’s rotation into electrical energy. This generated electricity serves two primary purposes: to recharge the battery and to supply power to the car’s electrical systems and accessories while the engine is operating.

Crucially, the alternator regulates the voltage output to maintain a consistent electrical supply throughout the vehicle. This voltage regulation prevents overcharging of the battery and ensures that all electrical components, from headlights to infotainment systems, receive the correct and stable amount of power. A properly functioning alternator is essential for maintaining battery charge and powering the car’s electrical systems reliably during driving in the UK.

Starter Motor and Solenoid

The starter motor and solenoid work in tandem to initiate the engine starting process. The solenoid is an electromagnetic switch that, when the ignition key is turned, activates the starter motor. The starter motor is a powerful electric motor that engages with the engine’s flywheel to crank the engine and begin the combustion process.

This coordinated action transforms electrical energy from the battery into mechanical motion, turning the engine over until it starts and runs on its own power. The starter motor and solenoid are essential for reliably starting the engine each time the car is used, making them critical components for vehicle operation in the UK.

Wiring Harness and Fuses

The wiring harness and fuses are fundamental to the safe and organized distribution of electricity throughout a car. The wiring harness is a network of wires that acts as the electrical pathways, channeling electricity to all the various components and systems within the vehicle. It connects everything from the battery and alternator to lights, sensors, and control units.

Fuses are strategically placed safety devices within the wiring harness. They are designed to protect the electrical system from damage caused by overloads or short circuits. If excessive current flows through a circuit, the fuse will blow, breaking the circuit and preventing damage to components. Together, the wiring harness and fuses ensure a safe and controlled flow of electrical power, preventing potential malfunctions and safeguarding the entire electrical network of the car, contributing to vehicle safety and reliability on UK roads.

Suspension and Steering

Smooth and easy manoeuvrability in vehicles relies on a complex suspension and steering system with several sensitive components working together.

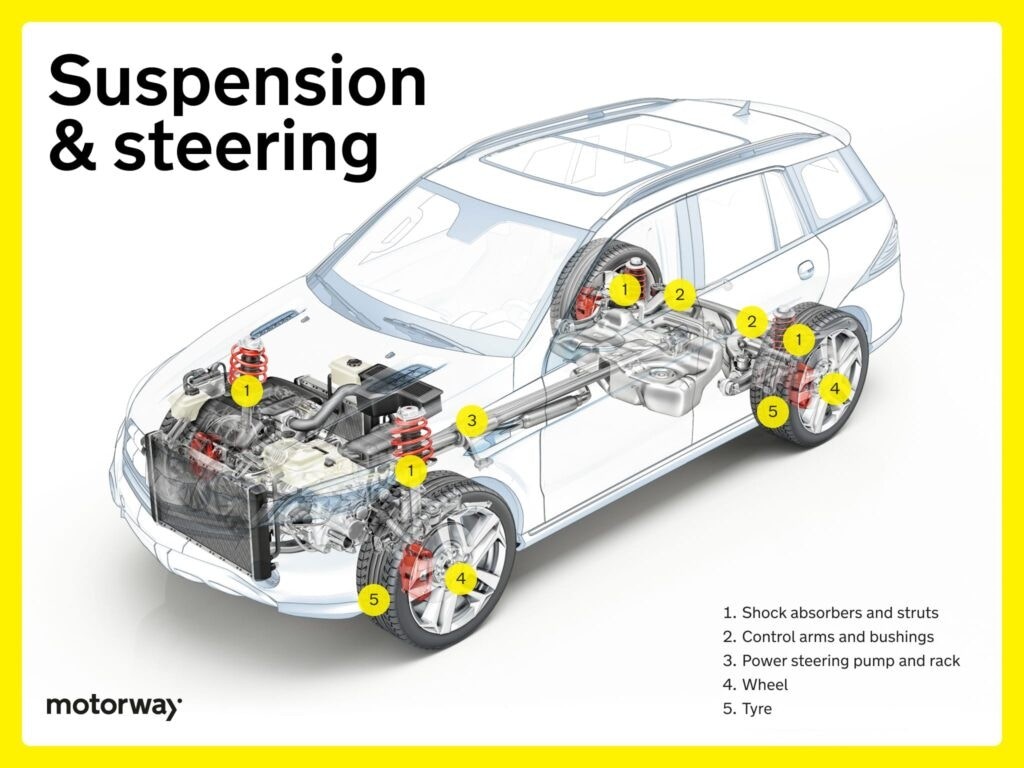

Shock Absorbers and Struts

Shock absorbers and struts are vital components of a car’s suspension system, working to ensure a comfortable and controlled ride, particularly important on varying UK road surfaces. Shock absorbers are designed to dampen and absorb shocks and vibrations from the road surface. Typically, a car has four shock absorbers, one at each wheel. They control the movement of the suspension springs, reducing bouncing and oscillations after encountering bumps or uneven surfaces.

Struts, often found at the front and sometimes rear of a car, are a structural part of the suspension system that combines the functions of shock absorption and suspension support. They provide both structural support for the vehicle’s weight and damping to control suspension movement. Together, shock absorbers and struts enhance driving comfort by minimizing the impact of road imperfections, ensuring a smoother, more stable, and enjoyable ride for both driver and passengers in the UK.

Control Arms and Bushings

Control arms and bushings are key elements in a car’s chassis, working to provide stability and smooth handling, contributing to safe and comfortable driving in diverse UK conditions. Control arms are suspension links that connect the vehicle’s suspension system to the chassis or frame. They allow the suspension to move up and down while maintaining wheel alignment.

Bushings are flexible rubber or polyurethane components that are fitted into the control arm joints. They act as cushions between the control arms and the frame, absorbing vibrations and reducing noise and harshness transmitted from the road. This combination of control arms and bushings helps to absorb road imperfections, maintain proper tyre alignment, and ensure a balanced and comfortable ride, contributing to vehicle stability and handling.

Power Steering Pump and Rack

The power steering pump and rack are crucial components of the power steering system, which makes steering easier and more responsive, particularly valuable in urban UK driving and parking situations. The power steering pump is engine-driven and generates hydraulic pressure. This pressurized hydraulic fluid is used to assist steering effort.

The steering rack is a mechanical component that translates the rotational movement of the steering wheel into the linear motion that turns the car’s wheels. In a power steering system, the rack is hydraulically assisted. The hydraulic pressure from the power steering pump acts on the steering rack, reducing the effort required from the driver to turn the steering wheel. Together, the power steering pump and rack provide precise and smooth manoeuvrability, making steering lighter and easier, enhancing driving ease and control.

Braking System

The braking system is a highly critical and finely-tuned area of your vehicle, with components rigorously tested in annual MOTs in the UK to ensure road safety.

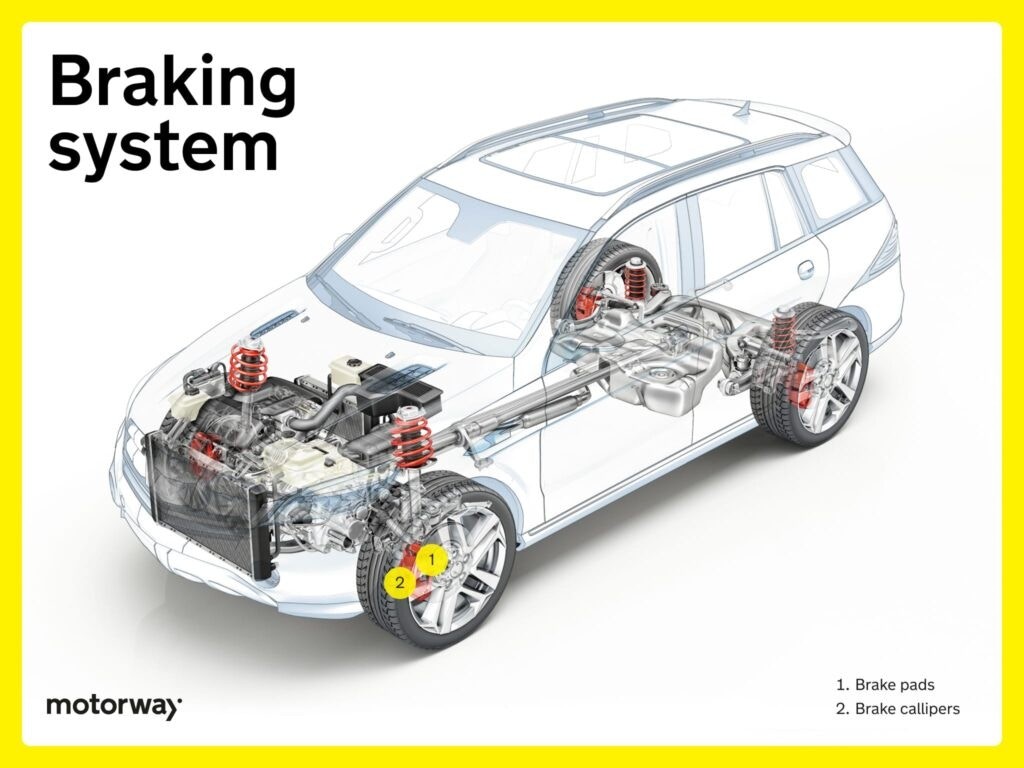

Brake Pads

Brake pads are fundamental frictional components in the braking system, responsible for creating the friction needed to slow down or stop the vehicle. Typically made of composite materials designed for high friction and heat resistance, brake pads press against the brake rotors when the brakes are applied.

This friction converts the kinetic energy of the moving vehicle into heat, effectively slowing the wheels and decelerating the car. Brake pads are designed to provide reliable and consistent braking performance. However, they are subject to wear over time with use and will eventually need replacement. Regular brake pad checks are part of routine car maintenance in the UK to ensure continued braking effectiveness and safety.

Brake Calipers

Brake calipers are essential components of the disc braking system, working in conjunction with brake pads and rotors to enable controlled deceleration. Brake calipers are positioned around the brake rotor at each wheel. Inside each caliper are pistons. When the brake pedal is pressed, hydraulic pressure is applied to these pistons.

The pistons in the caliper then clamp the brake pads firmly against the brake rotor. This clamping action generates the friction necessary to slow or stop the wheel’s rotation and, consequently, the vehicle. The precision and responsiveness of brake calipers are crucial for reliable and effective braking performance, directly contributing to overall driving safety, a paramount concern for drivers in the UK.

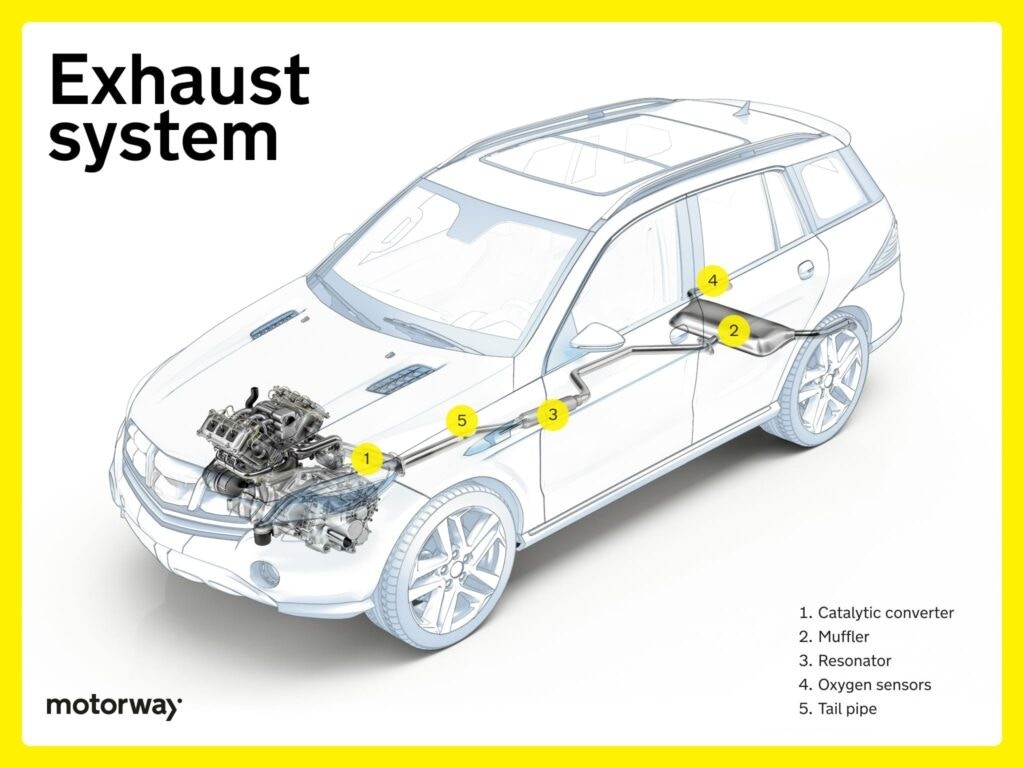

Exhaust System

Maintaining your car’s exhaust system is crucial for ensuring it runs cleanly and minimizes pollutant emissions, aligning with UK environmental standards and MOT requirements.

Catalytic Converter

The catalytic converter is a key component in the exhaust system of internal combustion engine cars, designed to reduce harmful emissions. It works through a process of catalysis to transform harmful gases produced by the engine, such as carbon monoxide, hydrocarbons, and nitrogen oxides, into less harmful substances.

Inside the catalytic converter, chemical reactions occur that convert these pollutants into carbon dioxide, water, and nitrogen. This process significantly reduces the levels of harmful emissions released into the atmosphere by the vehicle. The catalytic converter is a critical device for meeting emissions standards and contributing to cleaner air, making it a mandatory component for vehicles in the UK and many other countries.

Muffler and Resonator

The muffler and resonator are components within a car’s exhaust system that work together to control and reduce noise levels, contributing to a more pleasant driving experience and adhering to UK noise regulations. The muffler is primarily designed to reduce the overall noise generated by the engine’s exhaust. It uses a series of chambers and baffles to dampen sound waves and reduce the loudness of the exhaust noise.

The resonator works in conjunction with the muffler to fine-tune the sound frequencies of the exhaust. It helps to eliminate specific frequencies that can cause unwanted droning or booming sounds. Together, the muffler and resonator ensure that the vehicle operates with acceptable noise levels, enhancing driving comfort and complying with noise pollution standards, important considerations for vehicle operation in the UK.

Oxygen Sensors

Oxygen sensors are critical components in modern engine management systems, positioned in the exhaust system to monitor the oxygen levels in the exhaust gases. These sensors provide real-time data to the engine control unit (ECU), the car’s computer. The ECU uses this information to precisely adjust the air-fuel mixture being delivered to the engine.

By monitoring oxygen levels, the ECU can ensure that the engine operates with the optimal air-fuel ratio for efficient combustion. This precise fuel injection control optimizes fuel efficiency, reduces harmful emissions, and improves engine performance. Oxygen sensors play a vital role in ensuring that vehicles run cleanly and efficiently, contributing to both fuel economy and environmental responsibility in the UK.

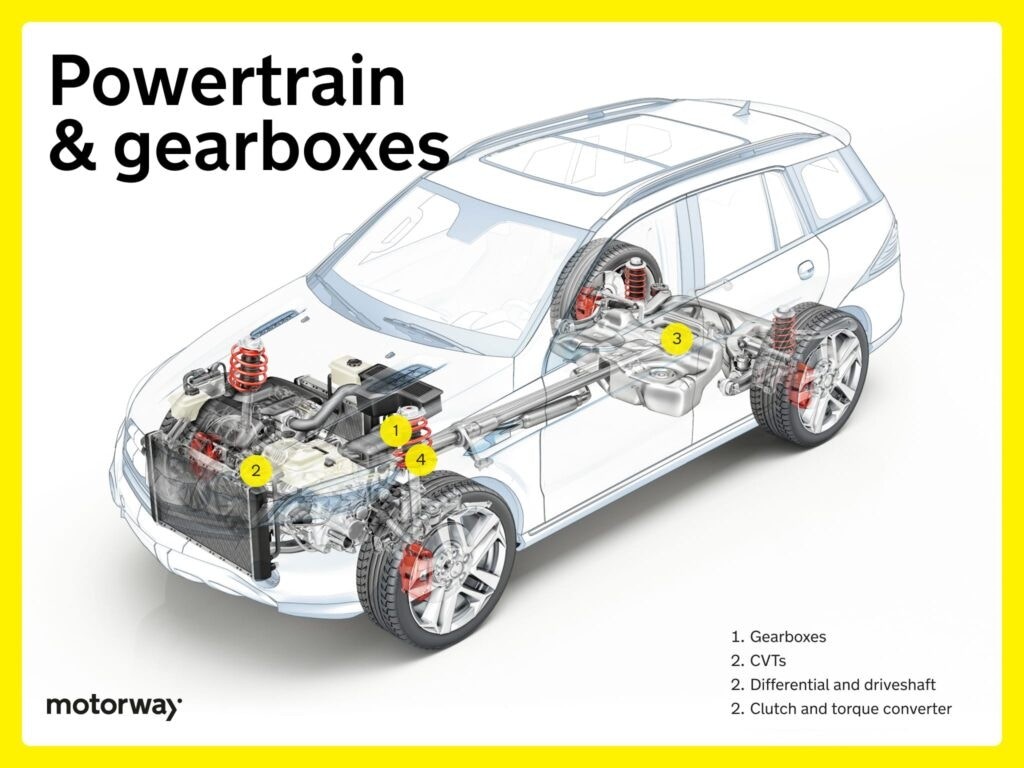

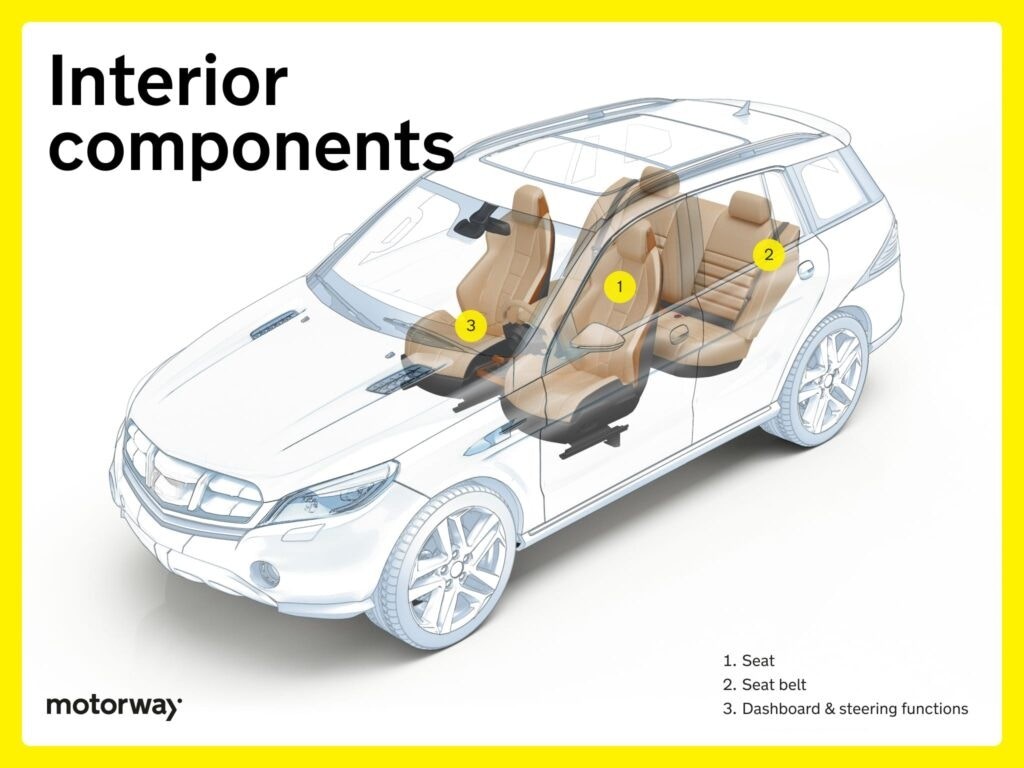

Interior Components

Maintaining your car’s interior components can significantly impact its resale value in the UK, as a well-maintained interior makes the car more appealing to potential buyers.

Seats & Their Belts

Car seats are designed to provide comfort and support for occupants, available in a wide range of materials, styles, and configurations to suit different preferences and vehicle types in the UK market. Modern car seats often include features like adjustable lumbar support, heating, and cooling for enhanced comfort.

Seat belts are essential safety devices designed to secure occupants in their seats during a collision or sudden stop. They are a mandatory safety feature in all cars in the UK. Modern seat belts often incorporate pretensioners, which tighten the belt in the event of an impact, and force limiters, which reduce the force exerted on the occupant’s chest, further enhancing safety. Regular checks of seat belts are crucial to ensure they are functioning correctly and providing maximum safety.

Dashboard & Steering Functions

The dashboard serves as the primary information and control center for the driver, displaying essential information and housing key controls. It typically relays critical data such as vehicle speed, engine RPM, fuel level, engine temperature, and warning lights. The dashboard provides a comprehensive overview of the vehicle’s operational status, ensuring driver awareness and informed driving decisions.

The steering wheel is more than just a steering control; it often integrates various functions and controls. Modern steering wheels commonly include controls for indicators, windscreen wipers, headlights, and multimedia systems, allowing drivers to operate these features without removing their hands from the wheel. Power-assisted steering is standard in most UK cars, making steering easier and more responsive. The dashboard and steering wheel functions together provide the driver with essential information and convenient control over vehicle operations.

Exterior Components

Maintaining your car’s exterior is important for both aesthetics and protecting the vehicle from the elements in the UK climate, potentially improving its resale value.

Features & Controls on Doors

The features and controls located on car doors are integral to enhancing convenience, security, and safety for drivers and passengers. Electric window controls are standard on virtually all modern cars in the UK, allowing for easy operation of windows. Central door locking systems, controlled from the driver’s door or remotely, are also standard for vehicle security. Electric mirror adjustment controls, typically positioned on the driver’s door, allow for easy adjustment of side mirrors for optimal visibility.

Many modern cars also incorporate advanced features into door controls, such as keyless entry systems, which allow for vehicle access without using a physical key, and power-operated doors, such as power tailgate or sliding doors on some MPVs. These door features and controls contribute significantly to the user-friendliness, convenience, and security of modern vehicles in the UK.

Wheels and Tyres

Types of Tyres and Their Functions

| Type of tyre | Function |

|---|---|

| Summer tyres | Specifically designed for optimal performance in warm weather conditions, excelling in both dry and wet grip and providing precise handling, ideal for UK summer driving. |

| Winter tyres | Engineered for cold climates, with specialized tread patterns and rubber compounds to provide enhanced traction and grip on snow and ice-covered roads, essential for UK winter conditions in some regions. |

| All-season tyres | Versatile tyres designed to offer a balance of performance across a range of weather conditions, providing acceptable traction and durability in both wet and dry conditions, a popular compromise for UK drivers. |

| Performance tyres | Designed for sporty driving, prioritizing handling, grip, and responsiveness at higher speeds, often chosen for performance cars or drivers seeking enhanced driving dynamics on UK roads. |

| Off-Road tyres | Built for challenging terrains such as mud, gravel, and rocks, featuring rugged treads and reinforced sidewalls for superior traction and durability in off-road conditions, suitable for 4×4 vehicles used off-road in the UK. |

| Run-flat tyres | Equipped with reinforced sidewalls that allow drivers to continue driving at reduced speeds for a limited distance even after a puncture, providing added safety and convenience in the event of a flat tyre on UK roads. |

| Touring tyres | Focused on providing a smooth and comfortable ride, ideal for long-distance journeys with low road noise, good handling, and enhanced durability, a good choice for frequent motorway driving in the UK. |

Wheel Construction Guide: Alloy vs. Steel Wheels

When considering wheel construction, several design approaches impact wheel properties and performance:

- One-piece construction: The wheel is manufactured from a single piece of material, typically alloy or steel. This is the most common construction method for both alloy and steel wheels, offering simplicity and structural integrity.

- Two-piece construction: The wheel consists of two main parts: the center and the outer rim, which are then joined together, usually by bolting or welding. Two-piece wheels are often found in performance or custom applications, allowing for some customization and repairability.

- Three-piece construction: The wheel is made up of three separate components: the center, the outer rim, and an inner hoop. This modular design allows for greater customization in terms of width, offset, and style, making three-piece wheels popular in the aftermarket and for custom builds.

- Forged construction: Forged wheels are created from a solid billet of metal that is compressed under extremely high pressure. This process results in wheels that are significantly stronger and lighter than cast wheels, making them ideal for high-performance and racing applications where weight and strength are critical.

- Multi-piece construction: This category encompasses wheels made from multiple components, typically including a center section, an outer rim, and fasteners. Multi-piece designs offer versatility in sizing, style, and customization options, catering to a range of aesthetic and performance preferences.

The choice of wheel construction influences weight, strength, durability, and aesthetics, allowing UK drivers to select wheels that match their driving needs and style preferences. Material choice is also a significant factor:

- Alloy wheels: Made from an alloy of metals, most commonly aluminum or magnesium. Alloy wheels are lighter than steel wheels, which improves handling and fuel efficiency. They also offer better heat dissipation for the brakes and are often chosen for their enhanced appearance and styling.

- Steel wheels: Constructed from steel, steel wheels are known for their robustness and durability. While heavier than alloy wheels, they are more cost-effective to produce and are well-suited for rugged driving conditions and winter use, offering good resistance to damage from kerbs and potholes common on UK roads.

Tyre Pressure Monitoring System (TPMS)

The Tyre Pressure Monitoring System (TPMS) is a crucial safety feature in modern vehicles, including those in the UK, designed to continuously monitor the air pressure within each tyre. TPMS uses sensors located in each wheel to measure tyre pressure in real-time.

This data is transmitted wirelessly to the vehicle’s computer system. If the tyre pressure in one or more tyres falls below a pre-set optimal level, the TPMS will trigger a warning light on the dashboard, alerting the driver to the issue. Maintaining correct tyre pressure, as monitored by TPMS, enhances safety, improves fuel efficiency, and extends tyre lifespan by reducing uneven wear and tear. TPMS is an important safety feature contributing to safer driving on UK roads.

FAQs

What Parts Are Under a Car?

Beneath a car, you will find a collection of essential components that are fundamental to its operation. These include the engine, the powertrain and transmission system, the suspension system, the exhaust system, and the fuel system. All these systems work interdependently to ensure the vehicle functions correctly, delivers power, handles effectively, and operates safely.

How Many Car Parts Are on a Car?

The total number of parts in a car is surprisingly high. Modern vehicles can contain upwards of 30,000 individual parts. This vast number encompasses all the components across the various systems, from the engine and transmission to the interior and electronics. This complexity highlights the intricate engineering and manufacturing processes involved in car design and production. Electric vehicles, while technologically advanced, typically have fewer moving parts than internal combustion engine cars, due to the simpler nature of their electric powertrains.

What Are the Important Parts of a Vehicle?

Several parts of a vehicle are considered critically important for its safe and reliable operation. These include the engine, which provides the power; the transmission, which transfers power to the wheels; the brake system, essential for stopping safely; the steering system, for directional control; the suspension, for ride comfort and handling; and the electrical components, which power all the car’s systems. Each of these plays a vital role in ensuring vehicle safety, performance, and functionality.

What Parts of a Car Can Be Sold Separately?

Many car parts can be sold separately, creating a market for used and aftermarket components. Common parts sold individually include engines, transmissions, body panels (like doors, bonnets, and bumpers), and specific electrical parts such as alternators and starters. The ability to sell parts separately provides options for repairs, replacements, upgrades, and recycling, contributing to cost-effective car maintenance and the automotive circular economy in the UK.

Why Is There a Shortage of Car Parts?

Shortages of car parts can occur due to a variety of factors affecting the global automotive supply chain. Disruptions to the supply chain, such as natural disasters, pandemics, or geopolitical events, can impact the production and availability of parts. Increased demand for specific components, sometimes driven by new car production or increased repair needs, can also lead to shortages. Manufacturing challenges, including raw material availability or production bottlenecks, can further exacerbate part shortages. Global events can have a cascading effect, disrupting production and distribution networks and leading to shortages of car parts in the UK and worldwide.

Need to Sell Your Car?

Looking to learn more about car ownership, maintenance, or selling your car in the UK? Explore our extensive guides here, covering topics from UK Clean Air Zones and car tax to number plate changes and part exchange.