Remote control (RC) cars have always been a thrilling hobby, blending engineering, creativity, and speed. Now, 3D printing technology takes this passion to a new level, allowing enthusiasts to design, create, and customize their own RC car parts. This comprehensive guide dives into the world of 3d Printer Rc Car Parts, exploring everything from materials and techniques to top models and performance tuning, perfect for hobbyists and experts alike looking to enhance their RC experience.

Mastering 3D Printing Techniques for RC Car Components

Creating durable and functional 3D printer RC car parts requires understanding optimal print settings and techniques. Achieving high-quality prints that can withstand the stresses of RC car operation involves fine-tuning various parameters.

Optimal 3D Print Settings for RC Parts

- Layer Height: For intricate and detailed parts like body panels or decorative elements, a layer height of 0.1-0.2mm is recommended. For larger, structural components such as chassis parts or suspension arms, a layer height of 0.2-0.3mm offers a balance between speed and strength.

- Infill Density: Most 3D printer RC car parts benefit from an infill density of 20-30% for general use, providing a good compromise between weight and strength. For parts subjected to high stress, such as gears or suspension mounts, increasing the infill to 50-100% ensures maximum durability.

- Wall Thickness: To enhance the robustness of your 3D printer RC car parts, a minimum wall thickness of 1.2mm (typically achieved with 3 perimeters or walls) is crucial. This adds significant strength and prevents parts from easily breaking under impact or stress.

- Top/Bottom Layers: Ensuring at least 4 top and bottom layers creates a smooth, solid surface finish and significantly increases the overall structural integrity of the printed part. This is particularly important for load-bearing components.

Choosing the Right 3D Printer Filament for RC Car Parts

The selection of 3D printer filament is paramount when creating 3D printer RC car parts. Different materials offer unique properties that cater to various needs, from flexibility to high strength and heat resistance.

| Filament Type | Advantages | Disadvantages | Ideal Applications for RC Car Parts |

|---|---|---|---|

| PLA (Polylactic Acid) | User-friendly printing, Minimal warping, Biodegradable options available | Low heat resistance, Can be brittle, Not ideal for outdoor use in hot climates | Decorative parts, Body panels, Interior components, Prototyping, Parts requiring fine details |

| PETG (Polyethylene Terephthalate Glycol) | Excellent durability and impact resistance, Chemical resistance, Good layer adhesion, Higher heat resistance than PLA | Can be prone to stringing, Slightly hygroscopic (absorbs moisture) | Functional parts, Chassis components, Suspension arms, Wheels, Outdoor use parts, Parts requiring a balance of strength and flexibility |

| ABS/ASA (Acrylonitrile Butadiene Styrene / Acrylonitrile Styrene Acrylate) | High strength and toughness, Heat resistance (especially ASA), Can be vapor smoothed for a glossy finish | More challenging to print (warping risk), Strong odor during printing (ABS), Requires higher print temperatures and enclosure | Mechanical parts under high stress, Gears, High-performance chassis parts, Parts requiring smooth surface finish, Outdoor use parts (ASA) |

| TPU (Thermoplastic Polyurethane) | Highly flexible and elastic, Excellent abrasion and impact resistance, Chemical resistance | More difficult to print (requires slow speeds and direct drive extruder), Can be stringy, Supports can be challenging to remove | Tires, Bumpers, Shock absorbers, Flexible joints, Parts requiring vibration dampening, Protective elements |

| Nylon (Polyamide) | Exceptional strength and wear resistance, Flexible in thin sections, High chemical and heat resistance | Hygroscopic (requires drying and storage in dry conditions), Most challenging to print (high temperatures, enclosure, bed adhesion issues) | Gears, Hinges, High-wear components, Parts requiring extreme durability and flexibility, Advanced mechanical parts |

Comparison of 3D Printer Filament Types for RC Car Parts

Post-Processing Techniques for Enhanced RC Parts

Once your 3D printer RC car parts are printed, post-processing can significantly improve their appearance, strength, and functionality.

- Sanding: Begin with a coarse grit sandpaper (e.g., 120-grit) to remove support marks and layer lines. Progress through finer grits (e.g., 220, 400, and even finer) for an increasingly smooth surface finish, preparing the parts for painting or other treatments.

- Priming and Painting: Applying automotive primer before painting is crucial for achieving a professional and durable finish on your 3D printer RC car parts. Automotive paints are designed to withstand outdoor conditions and provide excellent color and protection.

- Vapor Smoothing (for ABS parts): Acetone vapor smoothing is a technique specific to ABS (and ASA) filaments. Exposing ABS parts to acetone vapor in a controlled environment melts the surface layer, resulting in a smooth, glossy finish that eliminates layer lines and enhances structural integrity.

- Heat Treatment (Annealing PLA): Annealing PLA parts involves heating them in an oven at a low temperature (50-60°C) and allowing them to cool slowly. This process increases the crystallinity of PLA, making it significantly stronger and more heat resistant, although it may also cause slight shrinkage and deformation, so precise temperature control is necessary.

Essential Electronics and Components for 3D Printed RC Cars

Building a functional RC car with 3D printer RC car parts requires selecting and integrating the right electronic components. These components work together to power and control your custom-built vehicle.

Key Electronic Components for RC Cars

- Motor: Choose between brushed and brushless motors. Brushed motors are simpler and more affordable, suitable for beginners. Brushless motors offer higher performance, efficiency, and longevity, ideal for advanced users and racing applications. A 540 size motor with a KV rating of 2000-3000 is common for 1/10 scale RC cars.

- ESC (Electronic Speed Controller): The ESC regulates power flow from the battery to the motor, controlling speed and direction. Select an ESC that is compatible with your motor type (brushed or brushless) and has an appropriate current rating (e.g., 30-60A for 1/10 scale).

- Servo: A servo motor is responsible for steering your RC car. High-torque servos (5-10kg/cm) are recommended for reliable and responsive steering, especially for larger or heavier models.

- Receiver: The receiver picks up signals from the transmitter (remote control) and relays commands to the ESC and servo. Opt for a 2.4GHz receiver for reliable, interference-free operation and ensure it is compatible with your chosen transmitter.

- Battery: LiPo (Lithium Polymer) and NiMH (Nickel Metal Hydride) batteries are common choices. LiPo batteries offer higher energy density and performance, while NiMH batteries are more robust and require less delicate handling. For most 1/10 scale cars, 2S-3S LiPo batteries (7.4V-11.1V) are typical.

- Transmitter: The transmitter, or remote control, sends signals to the receiver to control the car. A minimum 2-channel transmitter is necessary (one for throttle/speed, one for steering), but transmitters with model memory and advanced features are beneficial for enthusiasts with multiple RC cars or for fine-tuning control.

Wiring and Connections for Robust Performance

Proper wiring and secure connections are critical for the reliable operation of your 3D printer RC car parts and electronics.

- Use silicone-insulated wire of appropriate gauge. For power circuits (battery to ESC, ESC to motor), 14-16 AWG wire is suitable. For signal circuits (receiver to ESC/servo), 22-24 AWG wire is sufficient. Silicone insulation offers flexibility and heat resistance.

- Solder all electrical connections for a robust and low-resistance connection. Use heat shrink tubing to insulate soldered joints, preventing shorts and ensuring durability.

- Install a power switch between the battery and ESC for safety and convenience. This allows you to easily turn the RC car on and off without disconnecting the battery.

Mounting Electronics Securely

Vibration and impacts are common in RC car operation, so secure mounting of electronics is essential when using 3D printer RC car parts.

- Use nylon screws and lock nuts to securely mount electronic components to the chassis. Nylon is non-conductive and helps dampen vibrations. Lock nuts prevent screws from loosening over time due to vibration.

- Apply double-sided foam tape beneath electronic components like the ESC and receiver for additional vibration dampening and shock absorption.

- Ensure adequate ventilation for heat-generating components like the ESC and motor to prevent overheating. Consider designing air vents or channels in your 3D printer RC car parts chassis to facilitate airflow.

Top 20 Inspiring 3D Printable RC Car Models

Explore these amazing 3D printable RC car models to spark your creativity and get started with your own 3D printer RC car parts projects.

1. Delorean DMC-12/BTTF Time Machine 3D Printed RC Car

Alt Text: 3D printed Delorean DMC-12 RC car model from Back to the Future with gull-wing doors.

Model URL:https://cults3d.com/en/3d-model/gadget/delorean-dmc-12-bttf-time-machine-3d-printed-rc-car-brett

Bring the iconic time-traveling Delorean from Back to the Future to life with this detailed and functional 3D printed RC car model.

2. RC 1/10 Dodge Challenger

Alt Text: 3D printed 1/10 scale RC Dodge Challenger muscle car in red.

Model URL:https://cults3d.com/en/3d-model/game/rc-1-10-dodge-challenger

This 1:10 scale 3D printed Dodge Challenger RC car captures the aggressive styling of the classic muscle car, perfect for cruising or drag racing.

3. OpenRC F1 Car – 1:10 RC Car

Alt Text: 3D printed OpenRC Formula 1 race car in 1:10 scale.

Model URL:https://www.thingiverse.com/thing:1193309

Experience high-speed racing with the OpenRC F1 car, a meticulously designed 1:10 scale Formula 1 model that showcases the potential of 3D printer RC car parts.

4. DIY RC Street Racing Car: One Week Classroom Project

Alt Text: Simple and functional 3D printed DIY RC street racing car for educational projects.

Model URL:https://www.thingiverse.com/thing:2653508

Ideal for beginners and educational purposes, this DIY street racing car is designed as a one-week classroom project, demonstrating accessible 3D printer RC car parts design.

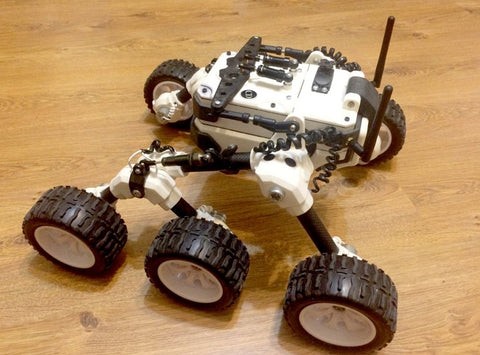

5. Martian Rover

Alt Text: 3D printed Martian Rover RC car designed for off-road exploration.

Model URL:https://www.thingiverse.com/thing:1318414

Explore new terrains with the 3D printed Martian Rover RC car, inspired by space exploration and built for off-road adventures using robust 3D printer RC car parts.

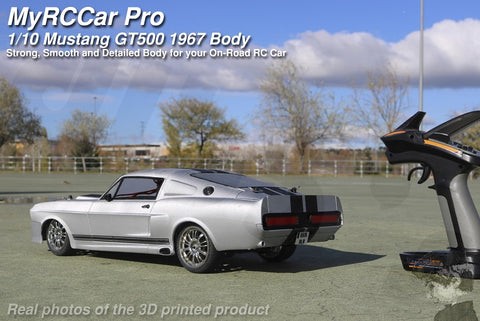

6. MyRCCar Mustang GT500 1967 1/10 On-Road RC Car Body

Alt Text: Classic 1967 Mustang GT500 Eleanor style 3D printed RC car body in 1/10 scale.

Model URL:https://cults3d.com/en/3d-model/game/myrccar-mustang-eleanor-style-1-10-on-road-rc-car-body

Recreate the iconic 1967 Mustang GT500 with this stunning 3D printed body, perfect for on-road RC car builds showcasing detailed 3D printer RC car parts.

7. OpenRC 1:10 4WD Touring Concept RC Car

Alt Text: Sleek and high-performance 3D printed OpenRC 1:10 4WD touring RC car for racing.

Model URL:https://cults3d.com/en/3d-model/game/openrc-1-10-4wd-touring-concept-rc-car

Experience competitive racing with the OpenRC 4WD Touring Car, designed for speed and precision using advanced 3D printer RC car parts.

8. PROTO36 RC Car Chassis

Alt Text: Customizable PROTO36 3D printed RC car chassis ready for component integration.

Model URL:https://cults3d.com/en/3d-model/game/proto36-rc-car-chassis

Build your custom RC car from the ground up with the PROTO36 chassis, a versatile and customizable platform made possible by 3D printer RC car parts.

9. OpenRC 1:10 4WD Truggy Concept RC Car

Alt Text: Rugged 3D printed OpenRC 1:10 4WD truggy RC car for off-road racing.

Model URL:https://cults3d.com/en/3d-model/game/openrc-1-10-4wd-truggy-concept-rc-car

Conquer rough terrain with the OpenRC Truggy, designed for off-road racing and durability with robust 3D printer RC car parts.

10. RS-01 Ayrton Senna’s 1993 McLaren MP4/8 Formula 1 RC Car

Alt Text: 3D printed RS-01 Ayrton Senna’s 1993 McLaren MP4/8 Formula 1 tribute RC car.

Model URL:https://cults3d.com/en/3d-model/various/rs-01-ayrton-senna-s-1993-mclaren-mp4-8-formula-1-rc-car

Pay homage to a racing legend with the RS-01, a 3D printed RC car replica of Ayrton Senna’s iconic 1993 McLaren MP4/8 Formula 1 car, made possible with detailed 3D printer RC car parts.

11. Ford Mustang GT500 1967 (RC Car)

Alt Text: Another angle of the classic Ford Mustang GT500 Eleanor 3D printed RC car.

Model URL:https://cults3d.com/en/3d-model/various/ford-mustang-gt500-eleonor-rc-car

Another stunning rendition of the 1967 Ford Mustang GT500, perfect for vintage car enthusiasts looking for detailed 3D printer RC car parts.

12. Tesla Roadster (RC Car)

Alt Text: Futuristic and sleek 3D printed Tesla Roadster RC car model.

Model URL:https://cults3d.com/en/3d-model/game/tesla-roadster-rc-car

Embrace the future with the 3D printed Tesla Roadster RC car, known for its speed and modern design, achievable with precise 3D printer RC car parts.

13. 1991 Mazda 787B 3D Printed RC Car

Alt Text: 1991 Mazda 787B Le Mans race car 3D printed RC model.

Model URL:https://cults3d.com/en/3d-model/various/1991-mazda-787b-3d-printed-rc-car

Recreate the legendary 1991 Mazda 787B Le Mans winner with this aerodynamic 3D printed RC car, showcasing the detail possible with 3D printer RC car parts.

14. Porsche 911 (992) GT3 RC Car

Alt Text: Elegant and sporty Porsche 911 (992) GT3 3D printed RC car.

Model URL:https://cults3d.com/en/3d-model/various/porsche-911-992-gt3-rc-car

Experience German engineering in miniature with the 3D printed Porsche 911 GT3 RC car, a symbol of performance and design achieved through 3D printer RC car parts.

15. MyRCCar 1/10 MTC Chassis Rigid Axles Version

Alt Text: Versatile MyRCCar 1/10 MTC chassis 3D printed for monster trucks and crawlers.

Customize your off-road beast with the MyRCCar MTC chassis, designed for monster trucks and crawlers and made with durable 3D printer RC car parts.

16. RC Car Hot Rod

Alt Text: Retro-styled 3D printed RC car Hot Rod Limo with vintage design.

Model URL:https://cults3d.com/en/3d-model/art/rc-car-hot-rod-limo

Stand out with the unique Hot Rod Limo RC car, blending retro style with modern RC technology through creative 3D printer RC car parts.

17. RC Car ‘Batmobile 1989’

Alt Text: Iconic 1989 Batmobile 3D printed RC car model in black.

Model URL:https://cults3d.com/en/3d-model/game/rc-car-batmobile-1989

Become the Caped Crusader with the 1989 Batmobile RC car, a sleek and stealthy design brought to life with 3D printer RC car parts.

18. 1.9 Beadlock Wheel Fiat Panda Old RC Car Axial TRX4 MST

Alt Text: Vintage Fiat Panda style 1.9 beadlock wheels 3D printed for RC crawlers.

Model URL:https://cults3d.com/en/3d-model/various/1-9-beadlock-wheel-fiat-panda-old-rc-car-axial-trx4-mst

Customize your RC crawler with these vintage-style Fiat Panda beadlock wheels, showcasing the customization options of 3D printer RC car parts.

19. RC Car 3D – Toy Story

Alt Text: Playful Toy Story inspired 3D printed RC car model for fans of all ages.

Model URL:https://cults3d.com/en/3d-model/various/rc-car-3d-toy-story

Bring the fun of Toy Story to your RC collection with this charming 3D printed RC car, a delightful project using 3D printer RC car parts.

20. RS-LM 2014 Audi R18 E-Tron Quattro “The Ali”

Alt Text: High-performance Audi R18 E-Tron Quattro Le Mans race car 3D printed RC model.

Model URL:https://cults3d.com/en/3d-model/various/rs-lm-2014-audi-r18-e-tron-quattro-the-ali

Experience Le Mans performance with the 3D printed Audi R18 E-Tron Quattro RC car, engineered for speed and precision using advanced 3D printer RC car parts.

Performance Tuning Guide for 3D Printed RC Cars

Optimizing the performance of your 3D printer RC car parts and overall vehicle involves careful tuning of various aspects, from weight distribution to aerodynamics and drivetrain.

Weight Distribution for Optimal Handling

- Aim for a slightly rear-biased weight distribution (approximately 55/45 rear/front) to improve acceleration and traction, especially during corner exits.

- Utilize lightweight materials for upper body parts and non-essential components to lower the center of gravity, enhancing stability and handling.

- Strategically position the battery pack and electronic components to achieve optimal balance. Experiment with different placements to fine-tune weight distribution.

Aerodynamics for Enhanced Speed and Stability

- Design a smooth underbody for your 3D printer RC car parts chassis to minimize air resistance and reduce drag, increasing top speed and efficiency.

- Incorporate a rear diffuser into the rear bumper or chassis design to increase downforce without significantly adding drag, improving stability at higher speeds.

- Experiment with different spoiler designs and positions to find the ideal balance between downforce and drag for your specific track conditions and driving style.

Suspension Tuning for Improved Cornering

- Adjust shock absorber oil weight and spring rates to match your driving style, track surface, and desired handling characteristics. Heavier oil and stiffer springs are suitable for high-speed tracks, while lighter oil and softer springs improve grip on bumpy surfaces.

- Fine-tune camber and toe angles to optimize tire contact patch during cornering, enhancing grip and cornering speed. Negative camber (top of the tire tilted inwards) is often beneficial for cornering.

- Consider 3D printing flexible suspension components, such as shock towers or suspension arms, using TPU filament to improve vibration absorption and impact resistance, especially on rough terrain.

Drivetrain Optimization for Efficiency

- Optimize gear ratios based on your motor’s KV rating, tire size, and typical racing conditions. Lower gear ratios (numerically higher) improve acceleration, while higher gear ratios (numerically lower) increase top speed.

- Use high-quality ball bearings throughout the drivetrain to minimize friction and improve efficiency, resulting in smoother operation and increased battery life.

- Design a lightweight and efficient spur gear and pinion gear setup using durable materials like nylon or carbon fiber-reinforced filaments to reduce rotating mass and improve drivetrain responsiveness.

Tire Selection and Customization for Grip

- Design and 3D print custom tire treads tailored to specific track surfaces. Slicks are ideal for smooth asphalt, while aggressive treads provide better grip on loose surfaces or off-road tracks.

- Experiment with different tire compounds by using flexible filaments like TPU with varying levels of shore hardness to achieve different grip levels. Softer compounds offer more grip but may wear faster.

- Ensure proper tire balancing, especially for high-speed applications, to minimize vibrations and maintain smooth operation at high speeds. Use tire balancing weights if necessary.

Motor and ESC Fine-Tuning for Power Delivery

- Choose a motor with a KV rating appropriate for your RC car’s size, weight, and intended use. Higher KV motors offer higher RPMs and top speed, while lower KV motors provide more torque.

- Optimize motor timing and gearing to achieve a balance between speed and acceleration, depending on your racing style and track layout. Adjustable ESCs allow for fine-tuning motor timing.

- Utilize a high-quality ESC with programmable features, such as throttle curves, braking force, and drag brake, to fine-tune power delivery and braking performance to your preferences.

Chassis Design for Handling and Durability

- Optimize chassis flex characteristics by strategically designing flex points or using materials with varying degrees of stiffness. Controlled chassis flex can improve handling and cornering grip.

- Design structural components with internal lattice structures or honeycomb infills to reduce weight while maintaining strength and rigidity, crucial for 3D printer RC car parts.

- Consider modular chassis designs for easy upgrades, repairs, and component swaps. Modular designs allow for greater customization and adaptability.

Electronics Cooling for Consistent Performance

- Design efficient air channels and vents in the body and chassis of your 3D printer RC car parts to promote airflow and improve cooling for heat-sensitive electronics.

- Integrate heat sinks onto the motor and ESC, potentially incorporating them directly into 3D printed mounting brackets or chassis elements for efficient heat dissipation.

- Consider active cooling solutions, such as small, lightweight fans mounted near the motor and ESC, for high-performance setups or operation in hot environments to prevent overheating and maintain consistent performance.

Print Settings for Strength and Precision

- Increase infill percentages for structural components, such as chassis parts, suspension mounts, and gears, to maximize strength and durability, especially for high-stress applications of 3D printer RC car parts.

- Adjust layer height and print speed to optimize surface finish and part strength. Lower layer heights generally result in smoother surfaces, while slower print speeds can improve layer adhesion and overall part strength.

- Experiment with different materials, including carbon fiber-infused filaments, for critical components requiring exceptional strength and stiffness, such as suspension arms or chassis braces.

Safety Considerations When Using 3D Printed RC Cars

While 3D printing offers incredible customization for RC cars, safety remains paramount, especially when dealing with batteries and electronics in 3D printer RC car parts projects.

Battery Safety Guidelines

RC cars commonly utilize LiPo (Lithium Polymer) or NiMH (Nickel Metal Hydride) batteries, which require careful handling to prevent hazards:

- Charging: Always use a charger specifically designed for your battery type. Never leave batteries charging unattended and charge them on a non-flammable surface, away from combustible materials.

- Storage: Store batteries in a cool, dry place, away from direct sunlight and extreme temperatures. LiPo batteries should ideally be stored at a storage charge level (typically around 3.8V per cell). Use LiPo safety bags for storage and charging to contain potential fires.

- Handling: Be extremely cautious to avoid punctures or physical damage to batteries. Damaged batteries can leak, overheat, or even ignite. Dispose of damaged or puffed batteries properly according to local regulations.

Heat Management for Material Integrity

Certain 3D printing materials, particularly PLA, are susceptible to warping or deformation at elevated temperatures. If your 3D printer RC car parts RC car utilizes high-power motors or electronics that generate significant heat, it’s crucial to:

- Opt for heat-resistant materials such as ABS, ASA, or PETG for components near heat sources like motors and ESCs.

- Ensure proper ventilation and airflow around heat-generating components by designing air vents or channels in your 3D printed chassis and body.

- Monitor component temperatures, especially during initial testing and in hot ambient conditions, to ensure materials are not exceeding their heat deflection limits.

Electrical Safety Practices

Maintaining electrical safety is essential when assembling and operating RC cars with 3D printer RC car parts:

- Ensure all electrical connections are properly insulated and secure. Exposed wires or loose connections can lead to short circuits, which can damage components, cause fires, or lead to battery failures.

- Use heat shrink tubing to insulate all soldered connections and exposed terminals.

- Regularly inspect wiring and connections for wear, damage, or looseness. Replace or repair any damaged wiring immediately.

- Avoid operating RC cars in wet conditions unless components are specifically waterproofed, as water can cause short circuits and damage electronics.

By adhering to these safety guidelines, you can enjoy the exciting world of 3D printed RC cars responsibly and effectively.

Frequently Asked Questions About 3D Printer RC Car Parts

Is it feasible to 3D print an entire car?

Yes, it is absolutely possible to 3D print numerous components of a car, including the body, chassis, and interior elements. While several companies have demonstrated the ability to 3D print full-size automobiles, these often involve a combination of 3D printed parts with traditionally manufactured components for the engine, powertrain, and critical mechanical systems. For RC cars, the vast majority of structural and cosmetic parts can be effectively 3D printed.

What is the typical timeframe for 3D printing a car?

The duration required to 3D print a car varies significantly based on the scale and complexity of the project. For a full-sized car or large-scale components, the printing process can extend from several days to weeks of continuous operation, depending on the printer size, print speed, and part complexity. For 3D printer RC car parts projects, which are considerably smaller in scale, the printing time typically ranges from 20 to 100 hours, depending on the model’s intricacy, material selection, and chosen print settings.

How long did the 3D printed Lamborghini project take to complete?

The ambitious 3D printed Lamborghini project, undertaken by a father-son team, spanned approximately two years from conception to completion. This extensive timeframe encompassed the design phase, 3D printing of numerous components, meticulous assembly of the vehicle, and integration of mechanical and electrical systems. The project demanded substantial dedication, with the car’s body and various parts being printed using a diverse array of materials and advanced 3D printing techniques to achieve the desired level of detail and functionality.