As a car owner or fleet manager, encountering a check engine light can be a source of stress. These lights are your vehicle’s way of communicating that something isn’t quite right. Thankfully, modern vehicles are equipped with an On-Board Diagnostics system, specifically OBD-II, which generates codes to help pinpoint the issue. Understanding these OBD2 codes, especially when using an OBD2 reader, is crucial for effective vehicle maintenance and repair.

This guide will delve into the world of OBD-II codes, explaining what they are, how to interpret them using your OBD2 reader, and why this knowledge is essential for keeping your vehicles running smoothly and efficiently.

What Exactly Are OBD2 Codes?

On-Board Diagnostics II (OBD-II) codes are essentially standardized messages from your vehicle’s computer. Think of them as your car’s internal language for reporting problems. These alphanumeric codes are generated by the vehicle’s onboard computer system when it detects an issue in various systems.

Your vehicle is a complex network of interconnected components, from the engine and transmission to the emissions system and beyond. These components constantly communicate with the central computer. When something deviates from the norm, the computer logs a specific OBD-II code.

These codes are designed to indicate a wide spectrum of issues, ranging from minor glitches to more serious malfunctions. The infamous “Check Engine” light illuminates when the computer detects that a system or component within the engine isn’t performing as expected, signaling the presence of an OBD-II code.

To access these codes, you’ll need an OBD2 reader. This device plugs into your vehicle’s OBD-II port, typically located under the dashboard on the driver’s side. Once connected, the OBD2 reader can retrieve the trouble codes, providing you with a numerical or alphanumeric code that points towards the potential problem area.

This code acts as a valuable diagnostic tool, guiding you or your mechanic in identifying the source of the issue. It’s a critical first step in troubleshooting and making informed decisions about vehicle repair and fleet management.

Breaking Down the Types of OBD2 Codes

When your OBD2 reader displays a code, knowing the category it belongs to can significantly narrow down the potential problem area. OBD-II codes are broadly classified into four main types, each relating to different vehicle systems:

Powertrain Codes: The “P” Series

Powertrain codes, starting with the letter “P,” are the most common type and indicate issues within the engine, transmission, and related drivetrain components. These codes are vital for diagnosing problems affecting your vehicle’s power and performance.

For example, the powertrain code P0301 indicates a cylinder 1 misfire. This means that cylinder number one in your engine is not firing correctly. A misfire can be caused by various issues, such as faulty spark plugs, ignition coils, fuel injectors, or vacuum leaks, all impacting engine performance and potentially leading to reduced fuel efficiency and engine damage if left unaddressed.

Body Codes: The “B” Series

Body codes, starting with the letter “B,” signal problems within the vehicle’s body systems. This category includes components like lighting, airbags, power windows, and climate control systems.

A body code such as B0010 could indicate a problem with the passenger-side airbag sensor. If this sensor malfunctions, the airbag system might not deploy correctly in an accident, compromising passenger safety. Body codes are crucial for ensuring the functionality of comfort and safety-related features.

Chassis Codes: The “C” Series

Chassis codes, starting with the letter “C,” point to issues within the vehicle’s chassis and related systems, including the suspension, steering, and braking systems.

For instance, a chassis code C0044 might indicate a problem with the Electronic Stability Control (ESC) system. ESC is vital for maintaining vehicle stability, especially during evasive maneuvers or on slippery surfaces. A malfunction in this system, indicated by a chassis code, can significantly impact vehicle handling and safety.

Network Communication Codes: The “U” Series

Network communication codes, starting with the letter “U,” highlight problems within the vehicle’s communication network. Modern vehicles rely on a complex network of modules and sensors to communicate and coordinate functions.

A common network communication code is U0100, which often signals a “Lost Communication With ECM/PCM.” This indicates a disruption in communication with the Engine Control Module (ECM) or Powertrain Control Module (PCM), the brains of the engine management system. This communication loss can stem from various issues, including wiring problems, module failures, or even a low battery, and can lead to significant drivability problems.

Reading the Language of OBD2 Codes: Decoding the Structure

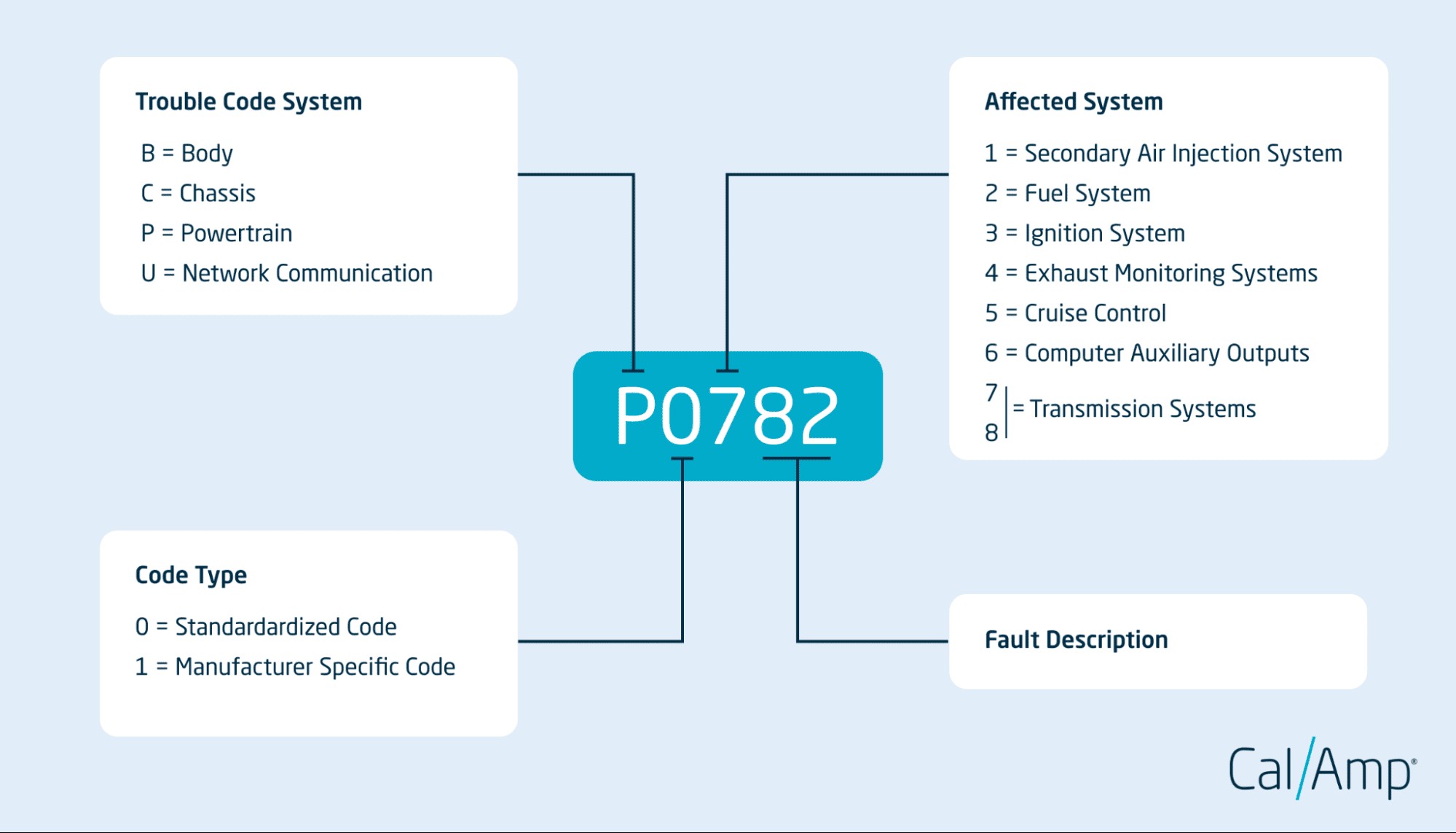

OBD-II codes are not random strings of characters; they follow a structured format of five characters, each component providing valuable information.

Understanding OBD2 Code Structure

Understanding OBD2 Code Structure

Understanding this structure allows for a more informed interpretation of the code displayed by your OBD2 reader.

First Character: Trouble Code System

The first character is always a letter indicating the primary system affected:

- P – Powertrain (Engine, Transmission)

- B – Body (Airbags, Accessories)

- C – Chassis (Braking, Suspension, Steering)

- U – Network Communication (Communication Bus)

Second Character: Code Type

The second character is a digit, indicating whether the code is generic or manufacturer-specific:

- 0 – Generic or Standardized Code: These codes are defined by the SAE (Society of Automotive Engineers) and are common across all vehicle makes and models. For example, P0300 (Random/Multiple Cylinder Misfire Detected) is a generic code.

- 1 – Manufacturer-Specific Code: These codes are defined by the specific vehicle manufacturer and provide more detailed information unique to that brand or model. For example, P1450 (Ford Specific: Evaporative Emission Control System Vent Control Valve Malfunction) is a manufacturer-specific code.

Third Character: Affected System (Subsystem)

The third character is a digit that further specifies the subsystem within the broader category indicated by the first character. While the specific meanings can be detailed, generally, the digits can correspond to systems like:

- 1 – Fuel and Air Metering

- 2 – Fuel and Air Metering (Injector Circuit)

- 3 – Ignition System or Misfire

- 4 – Auxiliary Emission Controls

- 5 – Vehicle Speed Controls and Idle Control System

- 6 – Computer Output Circuit

- 7, 8 – Transmission

Fourth and Fifth Characters: Specific Code

The fourth and fifth characters are digits that pinpoint the specific fault within the identified system and subsystem. These two digits provide the most granular detail about the problem. For example, in the code P0420, the “20” specifies “Catalyst System Efficiency Below Threshold (Bank 1).”

Clearing OBD2 Codes: When and How

While clearing OBD2 codes might seem like a quick fix, it’s generally not recommended without addressing the underlying issue. However, there are specific situations where clearing codes might be necessary or appropriate. Here are common methods:

Using an OBD2 Scanner for Code Clearing

OBD2 scanners are not only useful for reading codes but also for clearing them. After diagnosing and ideally resolving the issue indicated by the code, you can use your OBD2 reader to clear the code and turn off the check engine light.

Most OBD2 scanners have a “clear codes” or “erase codes” function. It’s crucial to understand that clearing the code without fixing the problem is only a temporary solution. The check engine light will likely reappear if the underlying issue persists. Clearing codes is most appropriate after repairs have been made to confirm the fix and reset the system.

The Drive Cycle Method

Some OBD2 codes, particularly those related to emissions, might clear themselves after a series of successful “drive cycles.” A drive cycle is a specific set of driving conditions (speed, duration, temperature) that allows the vehicle’s computer to re-run diagnostic tests.

While the exact drive cycle procedure varies by vehicle manufacturer, it generally involves a combination of city and highway driving at varying speeds. If the system re-tests and finds the issue resolved (perhaps it was a temporary sensor glitch), the code might clear automatically. However, this method is not reliable for all codes and is not a substitute for proper diagnosis and repair.

Consulting a Professional Mechanic

If you are unsure about the meaning of an OBD2 code, or if the check engine light returns after clearing the code yourself, it’s always best to consult a qualified mechanic.

Mechanics have advanced diagnostic tools and expertise to accurately pinpoint the root cause of OBD2 codes. They can perform thorough inspections, identify the faulty component, and carry out the necessary repairs. Furthermore, they can ensure that the problem is not just temporarily masked by clearing the code but is genuinely resolved, preventing potential further damage and ensuring vehicle safety.

Preventing OBD2 Codes: Proactive Vehicle Care

Preventing OBD2 codes from appearing in the first place is always the best approach, saving you time, money, and potential vehicle downtime. Proactive vehicle maintenance is key.

[Imagine a well-maintained engine, free of issues, symbolizing preventative car care.]

Two primary strategies are highly effective in preventing OBD2 codes:

Regular Vehicle Maintenance: Following the Schedule

Regular maintenance, including routine inspections, fluid changes, and timely replacement of wear-and-tear parts, is crucial for preventing OBD2 codes. Addressing minor issues before they escalate significantly reduces the likelihood of triggering codes and keeps your vehicle operating optimally.

- Routine Tasks: This includes oil changes, air filter replacements, spark plug inspections and replacements, brake system checks, tire rotations, and regular inspections of hoses and belts.

- Manufacturer’s Schedule: Adhere to the maintenance schedule outlined in your vehicle’s owner’s manual. This schedule is designed by the manufacturer based on mileage and time to ensure critical components are inspected and serviced at appropriate intervals.

- Professional Service: Regular servicing by a qualified mechanic ensures thorough inspections and early detection of potential problems. Mechanics can identify issues before they become severe enough to trigger OBD2 codes, saving you from more costly repairs down the line.

Using Quality Fuel and Fluids: The Right Ingredients

Using high-quality fuel and fluids is another essential preventative measure. Low-quality fluids can lack proper lubrication and protective properties, leading to increased wear and tear on engine and transmission components, potentially triggering OBD2 codes. Inferior fuel can cause incomplete combustion, leading to engine inefficiency and emissions-related codes.

- Fuel Quality: Choose reputable gas stations and use fuel that meets or exceeds the octane rating recommended for your vehicle. Higher quality fuel often contains detergents that help keep fuel systems clean.

- Manufacturer-Recommended Fluids: Always use fluids that meet or exceed the specifications recommended by your vehicle manufacturer, including engine oil, transmission fluid, coolant, brake fluid, and power steering fluid.

- Fluid Level Checks: Regularly check fluid levels, especially engine oil and coolant, and top them up as needed to ensure proper lubrication and cooling.

Managing OBD2 Codes for Fleets: Efficiency and Organization

For fleet managers, dealing with OBD2 codes across multiple vehicles can be complex. Implementing strategies for centralized tracking and efficient management is essential for minimizing downtime and controlling maintenance costs.

Here are effective approaches for handling OBD2 codes in a fleet environment:

Centralized OBD2 Code Tracking Systems

Centralizing OBD2 code tracking involves using a system to gather and manage code data from all fleet vehicles in one central location. This streamlines data access, analysis, and reporting. Advanced telematics systems, like the CalAmp iOn mentioned in the original article, can automate this process, providing real-time alerts and insights into vehicle health.

A centralized system offers several benefits:

- Real-time Visibility: Fleet managers gain immediate awareness of OBD2 code occurrences across the fleet.

- Historical Data Analysis: Analyzing historical code data can reveal patterns, identify recurring issues with specific vehicles or vehicle types, and inform preventative maintenance strategies.

- Simplified Reporting: Centralized data makes it easier to generate reports on vehicle health, maintenance needs, and repair costs.

Ongoing Fleet Monitoring with Telematics

Implementing ongoing fleet monitoring using telematics systems provides continuous data collection from vehicles, including location, performance metrics, and OBD2 code occurrences.

Telematics systems offer proactive fleet management capabilities:

- Real-time Alerts: Fleet managers are notified immediately when an OBD2 code is triggered in any vehicle.

- Proactive Maintenance: Early detection of codes allows for prompt action, preventing minor issues from escalating into major breakdowns.

- Reduced Downtime: Faster response times to OBD2 code issues minimize vehicle downtime and keep fleet operations running smoothly.

Prioritization of Repairs Based on Code Severity

Fleet managers should establish a system for prioritizing repairs based on the severity of OBD2 codes and their potential impact on vehicle operation.

Prioritization ensures efficient resource allocation and minimizes disruptions:

- Severity Levels: Categorize codes into severity levels (e.g., high, medium, low) based on potential safety risks and operational impact.

- Immediate Action: High-severity codes indicating critical safety or operational issues should be addressed immediately.

- Scheduled Maintenance: Lower-severity codes can be scheduled for repair during planned maintenance intervals, optimizing workflow and minimizing urgent repairs.

In Conclusion: Empowering Vehicle Health with OBD2 Understanding

OBD2 codes are your vehicle’s way of communicating its needs. By understanding what these codes mean, especially when utilizing an OBD2 reader, you gain valuable insights into your vehicle’s health and can take proactive steps to ensure its longevity and performance.

Whether you are a car owner managing your personal vehicle or a fleet manager overseeing a fleet of vehicles, mastering the basics of OBD2 codes is an empowering skill. It allows for informed decision-making, timely maintenance, and ultimately, keeps your vehicles running reliably and efficiently on the road.