Wheels are more than just aesthetic additions to your car; they are critical components that directly impact its performance, handling, and safety. Whether you’re looking to upgrade your vehicle’s style with aftermarket wheels or need to understand wheel components for maintenance, grasping the anatomy of a car wheel is essential. The world of wheels can seem complex, with various types, sizes, and terminologies. Understanding the difference between a wheel and a rim, and deciphering wheel specifications, empowers you to make informed decisions.

This guide serves as your comprehensive resource to navigate the intricacies of car wheel parts. We’ll delve into the names of each component, explore their functions within the wheel assembly, understand wheel manufacturing processes, discuss the significance of wheel size and offset, and explore the nuances of wheel upsizing. Equip yourself with the knowledge to confidently understand and discuss every aspect of your car’s wheels.

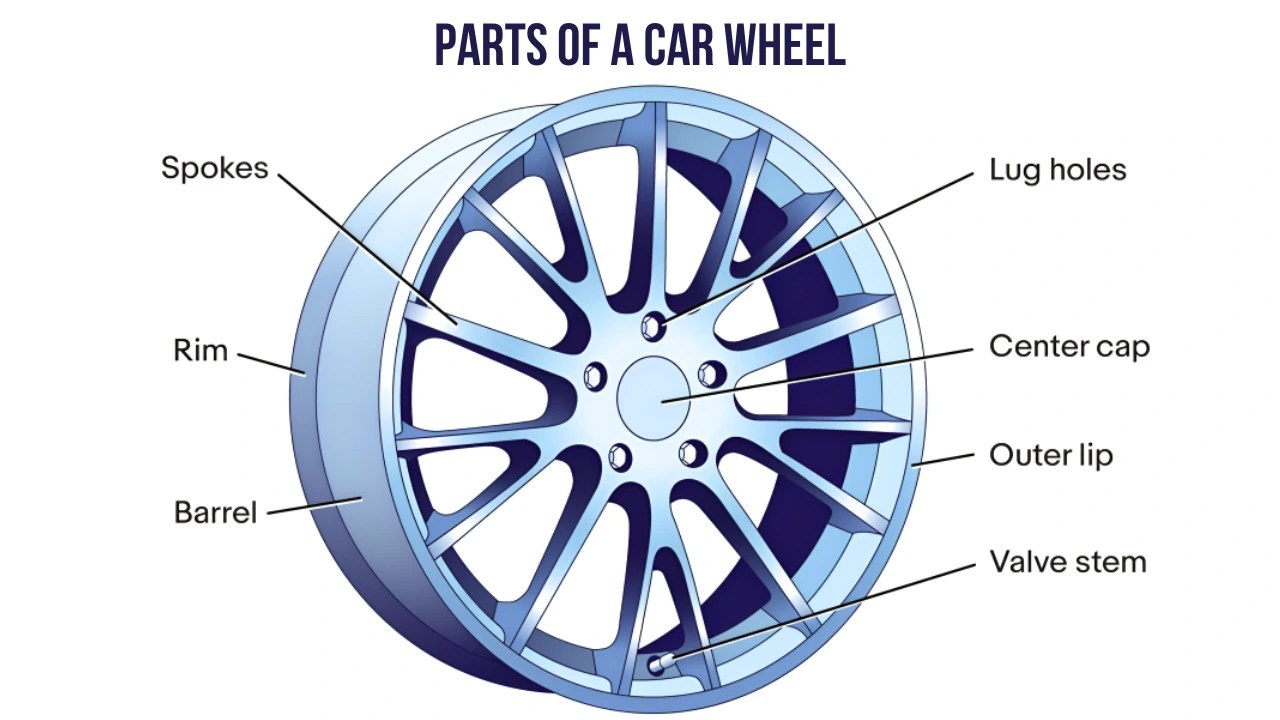

Essential Components of a Car Wheel: A Detailed Breakdown

While often used interchangeably, the term “wheel” encompasses a system of parts working in harmony. Let’s break down the key components that constitute a car wheel:

- Wheel Rim: The outer circular part of the wheel to which the tire is fitted.

- Tire: The rubber covering that fits around the rim, providing traction and cushioning.

- Valve Stem: A small valve that allows air or nitrogen to be added or removed from the tire.

- Hubcap/Wheel Cover: A decorative cover for the wheel’s center, often concealing lug nuts.

- Center Cap: A smaller, often branded cap covering the very center of the wheel.

- Lug Nuts: Fasteners that secure the wheel to the wheel studs.

- Wheel Studs: Threaded bolts attached to the hub that lug nuts screw onto.

- Wheel Spacers: Components used to adjust wheel offset, pushing the wheel further out from the hub.

- Wheel Bearings: Bearings that allow the wheel hub to rotate smoothly and freely.

- Wheel Seal: Seals that protect wheel bearings from contaminants.

- Wheel Bolts: Used in some vehicles (especially European) instead of studs and lug nuts to directly bolt the wheel to the hub.

- Wheel Locks: Special lug nuts or bolts requiring a key for removal, deterring wheel theft.

- TPMS Sensor (Tire Pressure Monitoring System Sensor): A sensor that monitors tire pressure and alerts the driver to low pressure.

- Rim Flange: The outer edge of the rim that helps retain the tire bead.

- Bead: The inner edge of the tire that seals against the rim flange, creating an airtight seal.

- Wheel Balancing Weights: Small weights attached to the rim to balance the wheel and tire assembly, preventing vibrations.

- Wheel Valve Cap: A cap that protects the valve stem from dirt and debris and helps prevent air leaks.

- Dust Cap: A cap that protects the wheel bearing from dust and contaminants.

In-Depth Look at Primary Wheel Parts

The car wheel system, while comprised of numerous parts, can be broadly categorized into three main functional areas: the rim and disc, the hub assembly, and the tire. Understanding these core components is crucial for grasping how a wheel functions.

1. Wheel Disc and Rim: The Foundation

Often referred to simply as the “rim,” the wheel disc is the metallic backbone of the wheel. It’s typically constructed from robust materials like steel or aluminum alloy to withstand the vehicle’s weight and driving forces. The rim is the outermost part of the disc, forming a circular edge where the tire is mounted.

Key Features of the Rim and Disc:

- Material: Steel rims are cost-effective and durable, commonly found on standard vehicles. Alloy rims (aluminum or magnesium) are lighter, enhancing performance and fuel efficiency, and offer greater design flexibility.

- Construction: Rims can be manufactured as one-piece, two-piece, or three-piece assemblies. One-piece rims are the most common and are typically cast or forged. Multi-piece rims allow for customization and repair flexibility.

- Size: Rim size is denoted by diameter and width, usually measured in inches (e.g., 17×7.5 inches). Diameter affects tire selection and overall vehicle stance, while width influences tire contact patch and handling.

- Design: Rim design is crucial for both aesthetics and structural integrity. The shape and spoke design of the disc significantly impact the wheel’s strength and appearance.

2. The Hub: Center of Rotation and Braking

The hub is the central component of the wheel assembly, serving as the crucial link between the wheel and the vehicle’s axle. It’s not just about rotation; the hub is also integral to braking and steering systems.

Key Functions of the Hub:

- Wheel Attachment: The hub provides the mounting point for the wheel to the axle, usually via wheel studs or bolts.

- Bearing Housing: The hub houses the wheel bearings, allowing for smooth, low-friction wheel rotation.

- Brake System Integration: The hub is directly connected to the brake rotor or drum, enabling the braking system to slow or stop the wheel.

- Steering Input (Front Wheels): In front-wheel-drive and all-wheel-drive vehicles, the hub is connected to the steering knuckle, allowing for directional control.

Wheel Hub Assembly: Modern vehicles often utilize a pre-assembled wheel hub assembly, integrating bearings, seals, and sometimes sensors (like ABS sensors) into a single unit. This simplifies manufacturing and maintenance.

Signs of a Failing Wheel Hub Assembly:

- Unusual noises: Growling, humming, or clicking sounds emanating from the wheel area, especially at speeds between 30-45 mph.

- Steering wheel vibration: Shaking or wobbling in the steering wheel, particularly at higher speeds.

- ABS warning light: Illumination of the Anti-lock Braking System (ABS) light on the dashboard, indicating a potential sensor malfunction within the hub assembly.

- Uneven tire wear: Premature or uneven wear on tires, potentially due to wheel bearing play.

3. Tires: The Point of Contact

Tires are arguably the most critical part of the wheel system, as they are the vehicle’s only contact point with the road surface. They are responsible for traction, cushioning, and handling.

Essential Tire Functions:

- Traction: Tires provide the grip necessary for acceleration, braking, and cornering. Tread patterns are designed to optimize traction in various conditions (dry, wet, snow).

- Cushioning: Tires absorb shocks and vibrations from road irregularities, contributing to ride comfort and protecting the suspension system.

- Load Bearing: Tires support the vehicle’s weight and distribute it across the contact patch.

- Steering Response: Tires play a crucial role in steering responsiveness and handling characteristics.

Tire Construction: Tires are complex structures made from various materials, including rubber compounds, steel belts, fabric plies, and reinforcing cords. The tread, sidewall, and bead are key areas of a tire, each serving specific functions.

Maintaining Tire Health: Proper tire inflation, regular tread depth checks, and timely rotations are essential for maximizing tire lifespan, safety, and performance.

Additional Wheel Components and Their Roles

Beyond the primary parts, several other components contribute to the wheel’s functionality and aesthetics:

- Spokes: Connecting the hub to the rim, spokes provide structural support and contribute significantly to wheel design. Spoke count, shape, and pattern influence both strength and visual appeal.

- Valve Stem: Allows for inflation and deflation of the tire. Modern valve stems often integrate TPMS sensors.

- Hubcaps and Center Caps: Primarily decorative, hubcaps and center caps can also protect wheel fasteners from dirt and corrosion.

- Counterweights (Balancing Weights): Attached to the rim to ensure wheel and tire balance, minimizing vibrations and ensuring smooth driving.

- Center Bore: The central hole in the wheel that centers it on the axle hub. Proper center bore matching is crucial for wheel fitment.

- Lug Holes: Holes in the wheel disc for attaching lug nuts or bolts.

- Outer Lip: The outermost edge of the rim, contributing to wheel aesthetics and sometimes affecting strength depending on wheel design.

- Bead Seats (Bead Rests): Surfaces on the rim where the tire bead sits and seals. Cleanliness here is vital for maintaining tire pressure.

- Drop Center: The deepest part of the rim’s barrel, aiding in tire mounting and removal.

- Flanges and Beads (Tire Interface): Rim flanges and tire beads create a secure, airtight seal between the tire and wheel.

Frequently Asked Questions About Car Wheel Parts

What are the basic parts of a car wheel?

The fundamental parts are the tire, rim, and hub. The rim supports the tire, and the hub connects the wheel to the vehicle.

What is the part of the car body above the wheel called?

This is called the fender (or wheel arch). In front, they are fenders, while rear ones are often integrated into the body panel.

What fasteners hold a wheel onto a car?

Wheels are typically held in place by wheel studs and lug nuts, or in some cases, wheel bolts.

Why are wheel parts important to understand?

Understanding wheel parts is crucial for maintenance, tire changes, wheel upgrades, diagnosing issues, and ensuring vehicle safety and performance.

What is the role of 4-wheel drive parts in the wheel system?

While not directly parts of the wheel itself, 4-wheel drive components like drive shafts and differentials transmit power to all four wheels, enhancing traction and off-road capability. These systems work in conjunction with the wheels to deliver power to the road.

By understanding the intricate parts of a car wheel, you gain a deeper appreciation for this essential vehicle system. Whether you’re a car enthusiast, a DIY mechanic, or simply a curious car owner, this knowledge empowers you to better maintain your vehicle and make informed decisions about wheel and tire maintenance and upgrades.