Every vehicle, from high-performance sports cars to robust trucks, depends on a fundamental component for mobility: the wheel. Wheels, alongside tires, are indispensable for any automobile, transforming them from static displays into functional modes of transport. While the core function remains consistent across vehicle types, car wheels vary significantly in size, style, and construction.

To deepen your understanding of automotive mechanics and maintenance, this article delves into the essential Car Wheel Name Parts. Knowing the anatomy of your wheels not only enhances your car care knowledge but also contributes to safer driving and prolonged vehicle lifespan. Let’s explore the components that make up this crucial system.

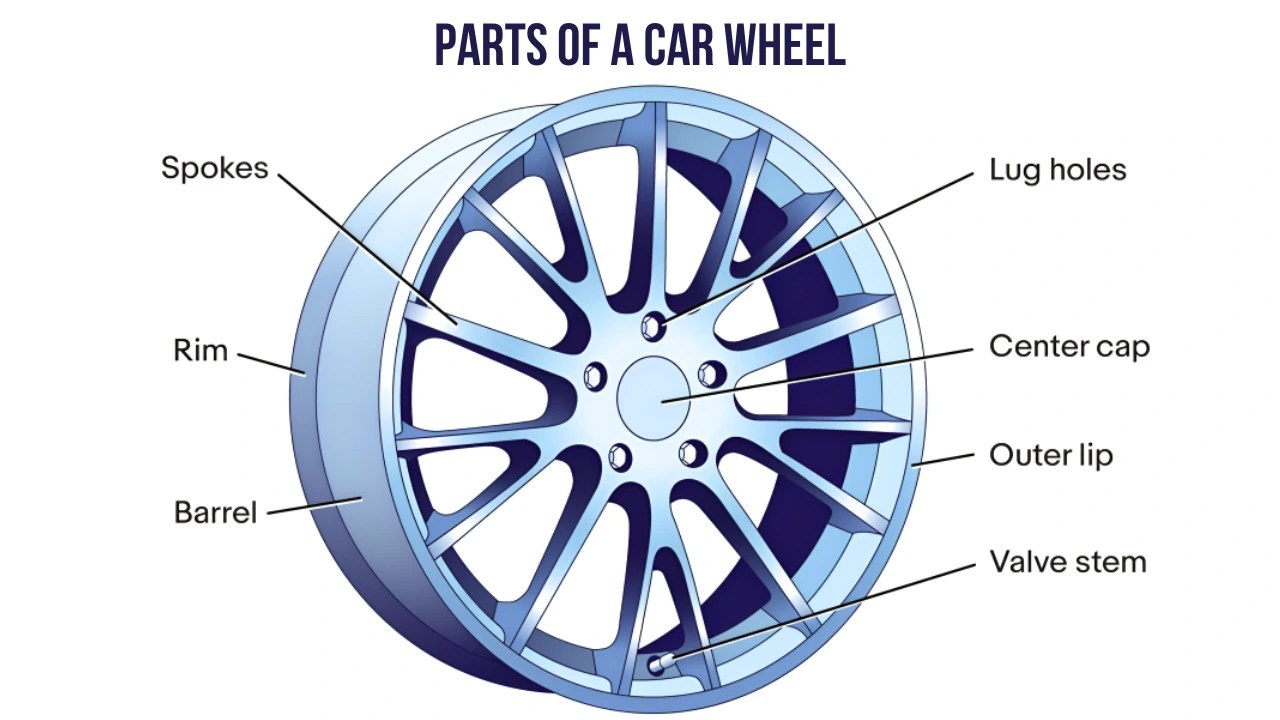

Diagram of Car Wheel Parts

Diagram of Car Wheel Parts

Key Components of a Car Wheel:

- Wheel Rim

- Tire

- Valve Stem

- Hubcap/Wheel Cover

- Center Cap

- Lug Nuts

- Wheel Studs

- Wheel Spacers

- Wheel Bearings

- Wheel Seal

- Wheel Bolts

- Wheel Locks

- TPMS Sensor (Tire Pressure Monitoring System)

- Rim Flange

- Bead

- Wheel Balancing Weights

- Wheel Valve Cap

- Dust Cap

Exploring the Anatomy of Car Wheels

A car wheel assembly is generally composed of three primary parts: the tire, the rim, and the hub. The tire encircles the rim, providing crucial grip and contact with the road surface. The hub serves as the central attachment point, connecting the wheel to the vehicle’s axle. Let’s break down these and other essential parts in more detail.

#1. Tire

The tire is arguably the most recognized part of the wheel. It’s the rubber component that directly interacts with the road. Modern tires are pneumatic, filled with air, which provides cushioning and a smoother ride. The evolution of tires from solid rubber to air-filled designs marked a significant advancement in ride comfort and safety.

Selecting the correct tires for your vehicle is paramount for safety and performance. Tires are engineered to provide traction in various conditions, including wet, icy, and snowy roads, enhancing vehicle handling and stability, especially in challenging weather.

#2. Rim

Consider the rim as the structural foundation of the wheel assembly. It’s the metal framework upon which the tire is mounted. The rim provides shape and support to the tire, allowing it to be inflated and maintain its form. Rims are typically manufactured from steel or aluminum alloys, chosen for their strength and durability, and are available in a vast array of designs and finishes.

From functional steel rims often seen on basic models to aesthetically polished chrome or alloy rims, the style can greatly vary. Truck rims are generally built to be more robust to handle heavier loads, often prioritizing function over pure aesthetics. The dimensions of the rim, specifically its diameter and width, dictate the compatible tire sizes.

#3. Hub

The hub is the central core of the wheel, acting as the interface between the wheel and the vehicle. It’s where the rim is attached and is integral to the braking system, often housing components like brake pads, calipers, and rotors. These components are connected to the axle, facilitating both movement and braking of the vehicle.

Extending from the hub’s center are typically wheel studs or bolts, which are used to secure the wheel to the vehicle using lug nuts or wheel bolts. The hub is essentially the mechanical heart of the wheel assembly, ensuring secure attachment and functional integration with the vehicle’s chassis.

#4. Spokes

Spokes are structural elements that bridge the hub and the rim, contributing significantly to the wheel’s integrity. They form the visible face of the wheel along with the hub. In multi-piece wheels, the spoke section is often manufactured separately and then bolted to the barrel.

Beyond their structural role, spokes are a key element in wheel design, contributing significantly to the aesthetic appeal. Custom wheels offer a variety of spoke styles, differing in number, thickness, shape, and pattern. While five-spoke designs are common for their balanced engineering, the number of spokes has a minimal impact on performance compared to materials and construction methods. Choosing a wheel with spokes often comes down to personal style preference.

#5. Outer Lip (Dish)

The outer lip, sometimes referred to as the dish, is the area of the wheel extending outwards from the spokes to the edge of the rim. The depth of the dish is largely an aesthetic choice. Wheels with spokes set far back from the outer edge are known as deep-dish wheels, a style often chosen for visual impact.

However, a deeper dish can make the wheel face more susceptible to damage from impacts. It’s a design element that balances visual appeal with practical considerations.

#6. Barrel

The barrel is the outermost cylindrical part of the wheel rim, crucial for tire mounting. It’s designed with features that facilitate secure tire installation and retention. A key feature within the barrel is the drop center, the narrowest diameter section.

The position of the drop center—closer to the front or back face of the wheel—defines whether it’s a front mount or reverse mount wheel, influencing tire mounting procedures. The barrel edges are flared to create flanges, which are critical for preventing the tire from slipping off the rim during use.

#7. Beads

Located just inside the rim flanges are the beads. These are flat surfaces where the tire edges (also called beads) seat against the wheel rim. The tire beads create an airtight seal against these surfaces when inflated, essential for maintaining tire pressure and ensuring proper tire function.

#8. Flanges

Flanges are the flared edges on both the inboard and outboard sides of the wheel rim barrel. Their primary function is to retain the tire securely on the wheel, preventing it from detaching, especially under load or during cornering.

#9. Mounting Humps

Mounting humps are small ridges positioned inside each bead seat on the rim. These humps play a vital role in preventing tire bead slippage and ensuring the tire remains firmly seated against the wheel rim, further enhancing safety and tire performance.

#10. Drop Center

The drop center is the section with the smallest diameter within the wheel barrel. This ingenious design feature is crucial for tire installation. It allows the tire to be fitted onto the wheel without excessively stretching the tire beads, making tire changes more manageable.

#11. Center Cap

The center cap is a detachable cover for the center bore on the wheel’s exterior face. It primarily serves an aesthetic purpose, concealing the wheel hub components. On many modern vehicles, it also provides protection to the lug nuts or bolts from dirt and damage.

#12. Valve Stem

The valve stem is inserted into a dedicated hole in the rim. This metal valve is used to inflate or deflate the tire and allows for pressure monitoring. It’s a critical component for maintaining correct tire pressure, which is essential for safety, fuel efficiency, and tire longevity.

#13. Wheel Balancing Weights

Small weights are attached to the wheel rim to balance the wheel and tire assembly. These weights counteract any imbalances in the wheel or tire, preventing vibrations at higher speeds and ensuring a smoother ride, as well as reducing uneven tire wear and stress on suspension components.

#14. Wheel Studs & Lug Nuts/ Wheel Bolts

Wheel studs are threaded fasteners permanently mounted to the vehicle’s hub. Lug nuts are then screwed onto these studs to secure the wheel. In some vehicles, wheel bolts are used instead of studs and nuts, threading directly into the hub to hold the wheel in place. Both systems are critical for securely attaching the wheel to the vehicle.

#15. Wheel Spacers

Wheel spacers are installed between the wheel and the hub. They are used to adjust the wheel offset, which can improve a vehicle’s stance or provide clearance for larger brake components. Spacers should be selected and installed carefully to maintain vehicle safety and handling characteristics.

#16. Wheel Bearings

Wheel bearings are located within the hub and allow the wheels to rotate smoothly with minimal friction. They are critical for wheel rotation and support the vehicle’s weight. Properly maintained wheel bearings are essential for smooth, efficient, and safe vehicle operation.

#17. Wheel Seal & Dust Cap

Wheel seals are used to protect the wheel bearings from contaminants like dirt and moisture, preventing premature wear and failure. Dust caps further protect the wheel bearings, especially the outer bearings, from road debris and dust, extending the life of the bearings and maintaining their performance.

#18. TPMS Sensor

The Tire Pressure Monitoring System (TPMS) sensor is often integrated into the valve stem or attached to the wheel rim inside the tire. This sensor monitors tire pressure and alerts the driver if the pressure drops below a safe level, improving safety and preventing tire damage from underinflation.

#19. Wheel Locks

Wheel locks are specialized lug nuts or bolts designed to prevent wheel theft. They require a unique key for removal, providing an added layer of security for valuable wheels and rims.

#20. Wheel Valve Cap

The valve cap screws onto the valve stem. It protects the valve core from dirt and debris and helps maintain an airtight seal. While seemingly minor, it plays a role in preventing slow leaks and maintaining correct tire pressure.

Understanding these car wheel name parts provides a solid foundation for appreciating the complexity and engineering behind a component we often take for granted. For further automotive knowledge, explore resources on car engine parts and general car parts.

Frequently Asked Questions (FAQs)

Q: What are the main parts of a car wheel?

A: The primary components are the tire, rim, and hub. The rim supports the tire, while the hub connects the wheel to the vehicle.

Q: What is the part of the car body above the wheel called?

A: Typically, the panel above the front wheels is called a fender. For vehicles with wide bodies that enclose the tire, the fender forms the wheel well and might not be directly visible from above.

Q: How is a wheel held onto a car?

A: Wheels are typically secured using wheel studs and lug nuts, or wheel bolts. Wheel studs are fixed to the hub, and lug nuts tighten onto them. Wheel bolts thread directly into the hub.

Q: What are the components within the wheel hub area?

A: The hub area often houses brake components like brake rotors, calipers, and pads, along with wheel bearings that allow for smooth rotation.

Q: What are the parts involved in a four-wheel-drive system related to the wheels?

A: While not directly wheel parts, related driveline components include drive shafts and differentials, which transmit power to all four wheels in a 4WD system.