Driving safely relies heavily on a well-functioning brake system. As a car owner, understanding the components of your car’s brakes is not just for mechanics – it’s crucial for your safety and wallet. Knowing the different brake parts, how they work, and when they might need attention can save you money on repairs and potentially prevent accidents. This guide will explore the essential Brake Parts For Cars, detailing their functions and importance in both disc and drum brake systems.

Chapter 1: Disc Brake System Components

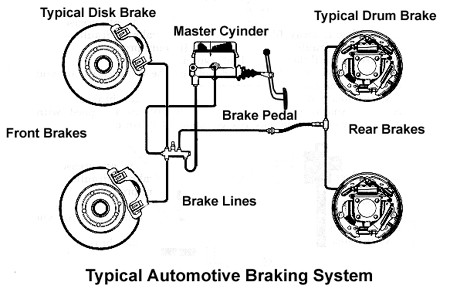

Disc brakes are commonly found on the front wheels and sometimes all wheels of modern vehicles. They offer effective stopping power and are a vital part of your car’s brake parts. Here are the key components:

– Brake Pads

Brake pads are a critical wear item in your car’s brake parts. These components are designed to create friction against the brake rotor, slowing down or stopping the wheel. They are essentially friction blocks that are pressed against the rotor when you apply the brakes.

Made from various materials like ceramic, semi-metallic, or organic compounds, brake pads are engineered for high friction and heat resistance. Over time, the friction material on brake pads wears down, requiring replacement to maintain optimal braking performance. Different types of brake pads are available, each offering varying levels of performance, durability, and noise characteristics.

– Brake Rotor

The brake rotor, also known as a brake disc, is another essential part of disc brake systems. It’s a metal disc that rotates with the wheel. The brake pads clamp down on this rotor to create friction and slow the wheel’s rotation.

Brake rotors must be robust to withstand high temperatures generated during braking. Like brake pads, rotors also wear down over time, although typically at a slower rate. Worn or damaged rotors can reduce braking efficiency and cause vibrations or noises. Regular inspection of brake rotor thickness and condition is important for maintaining safe braking.

– Brake Caliper

The brake caliper is the hydraulic clamp of the disc brake system. Its primary function is to house the brake pads and pistons, and to exert force on the brake pads when you press the brake pedal.

When hydraulic pressure from the brake master cylinder is applied, the caliper pistons push the brake pads against the rotor. Calipers need to be robust and function smoothly to ensure even and effective braking. There are two main types: fixed calipers and floating calipers, each with slightly different mechanisms for applying pressure to the brake pads. Leaks in the caliper, indicated by brake fluid loss, require immediate attention and repair or replacement.

Chapter 2: Drum Brake System Components

Drum brakes, while less common on front wheels today, are still utilized, particularly on the rear wheels of some vehicles. They are another type of car brake parts and operate differently from disc brakes. Key components of a drum brake system include:

– Brake Shoes

Similar in function to brake pads in a disc system, brake shoes are curved friction components in drum brakes. They are lined with a friction material that presses against the inside surface of the brake drum to create braking force.

Brake shoes are actuated by the wheel cylinder and are designed to expand outwards into the rotating brake drum. Like brake pads, the friction material on brake shoes wears down and requires periodic replacement.

– Brake Drum

The brake drum is a cylindrical metal component that rotates with the wheel. It serves as the contact surface for the brake shoes. When the brake shoes press outwards against the inner surface of the drum, friction is created, slowing the wheel.

Brake drums are typically made of cast iron and are designed to withstand the heat generated during braking. They can become worn or warped over time, which can affect braking performance. Inspecting brake drums for wear and damage is part of routine brake maintenance.

– Backing Plate

The backing plate is the foundation of the drum brake assembly. It’s a stationary plate that provides a mounting point for all other drum brake components, including the brake shoes, wheel cylinder, and springs.

The backing plate also helps protect the brake components from road debris and supports the overall structure of the drum brake system.

Chapter 3: Brake System Hardware and Accessories

Beyond the main components of disc and drum brakes, several other brake parts and hardware elements are crucial for the overall functionality of a car’s brake system. These include:

– Return Springs

Return springs are specific to drum brake systems. Their role is to retract the brake shoes away from the brake drum when the brake pedal is released. This ensures that the brakes are not dragging and allows the wheels to rotate freely.

These springs are essential for proper drum brake operation and preventing unnecessary wear and heat buildup.

– Wheel Cylinder

In drum brake systems, the wheel cylinder is a hydraulic component that actuates the brake shoes. It contains pistons that are pushed outwards by hydraulic pressure, forcing the brake shoes against the brake drum.

Wheel cylinders are susceptible to leaks of brake fluid, which can compromise braking performance. Signs of leakage necessitate immediate replacement of the wheel cylinder.

– Anti-Lock Braking System (ABS)

Anti-lock brakes (ABS) are a critical safety accessory in modern vehicles. ABS is designed to prevent wheel lock-up during hard braking, especially on slippery surfaces. By preventing wheel lock, ABS helps maintain steering control and shortens stopping distances in emergency braking situations.

ABS systems utilize sensors to detect wheel deceleration and modulate brake pressure to each wheel individually, preventing skidding and maximizing braking effectiveness.

Chapter 4: Types of Brake Systems

While we’ve discussed the components of disc and drum brakes, it’s also important to understand the broader categories of brake systems based on their operation:

- Electromagnetic Braking System: Uses electromagnetic force to slow or stop a vehicle, often found in hybrid and electric vehicles for regenerative braking.

- Hydraulic Brake System: The most common type in cars, using hydraulic fluid to transmit force from the brake pedal to the brake components at the wheels. Both disc and drum brakes are typically hydraulically actuated.

- Mechanical Brake System: Relies on mechanical linkages, such as cables and rods, to apply the brakes. Often used in parking brakes or older vehicle designs.

- Servo Brake System (Vacuum Assisted Braking): Utilizes vacuum pressure from the engine intake manifold to assist the driver in applying the brakes, reducing pedal effort.

Disc brakes and drum brakes are the two primary types of brakes in terms of their physical mechanism, but they both often function within a larger hydraulic brake system. Understanding these distinctions is key to grasping how your car’s brake parts work together.

Conclusion

Knowing the different brake parts for cars and their functions is more than just technical knowledge; it’s about being a responsible and informed driver. Whether it’s brake pads, rotors, calipers, shoes, or drums, each component plays a vital role in ensuring your vehicle can stop safely and effectively. Regular maintenance and understanding of these brake parts can contribute to safer driving and prevent costly repairs down the line. By familiarizing yourself with these components, you’re taking a proactive step in vehicle safety and maintenance.