Understanding your vehicle’s health is becoming increasingly accessible thanks to On-Board Diagnostics (OBD2). At the heart of OBD2 are PIDs – Parameter IDs – which are codes used to request data from your car’s computer. If you’re looking to dive deep into vehicle diagnostics, data logging, or even develop your own automotive applications, mastering the Can Obd2 Pid List is essential.

This guide, brought to you by carparteu.com, your expert resource for automotive repair and technology, will provide a comprehensive overview of OBD2 PIDs. We’ll explore what they are, how they work within the CAN bus system, and provide you with a detailed list to help you decode your vehicle’s data. We aim to go beyond basic explanations, offering practical insights and resources to empower both beginners and experienced professionals.

Understanding OBD2 PID table overview for vehicle diagnostics and parameter identification.

Decoding OBD2 PIDs: Your Key to Vehicle Data

OBD2 is essentially your car’s built-in self-diagnostic system. As we detailed in our introductory guide to OBD2, it provides a standardized way to interface with vehicles, from cars to trucks. Mechanics use OBD2 scan tools to diagnose issues when the check engine light comes on, but its capabilities extend far beyond just error codes.

The SAE J1979 standard defines a set of public OBD2 PIDs. Think of these PIDs as specific addresses that you can query to get real-time data about your vehicle’s operation. Tools like OBD2 scanners, CAN bus interfaces, and OBD2 data loggers utilize these PIDs to request information.

To request data, these tools connect to your vehicle’s OBD2 port (typically located under the steering wheel) and send specific CAN bus frames. For instance, to request the OBD2 PID for ‘Vehicle Speed’ (PID ‘0D’), you would send a CAN frame with the ID 7DF and the data payload 02 01 0D 55 55 55 55 55.

If your vehicle supports this PID, it will respond with an OBD2 response frame on the CAN bus, usually with CAN ID 7E8. The data payload might look like 03 41 0D XX AA AA AA AA, where ‘XX’ represents the vehicle speed in hexadecimal km/h.

Programmatic Access to CAN OBD2 PID Lists: DBC, CSV, and More

For those working with OBD2 data programmatically, having the data in structured formats is crucial. That’s where formats like DBC and CSV come in handy.

Our OBD2 DBC file is designed for use with CAN bus software tools. It allows you to easily decode raw CAN frames containing OBD2 PID responses. This is invaluable if you’re using an OBD2 data logger or a OBD2-to-USB interface to record vehicle data.

The OBD2 CSV file provides similar information to the DBC file and the table we’ll explore below, but in a simple CSV format. This is perfect for those who want to implement their own OBD2 PID decoding logic in scripts or custom applications.

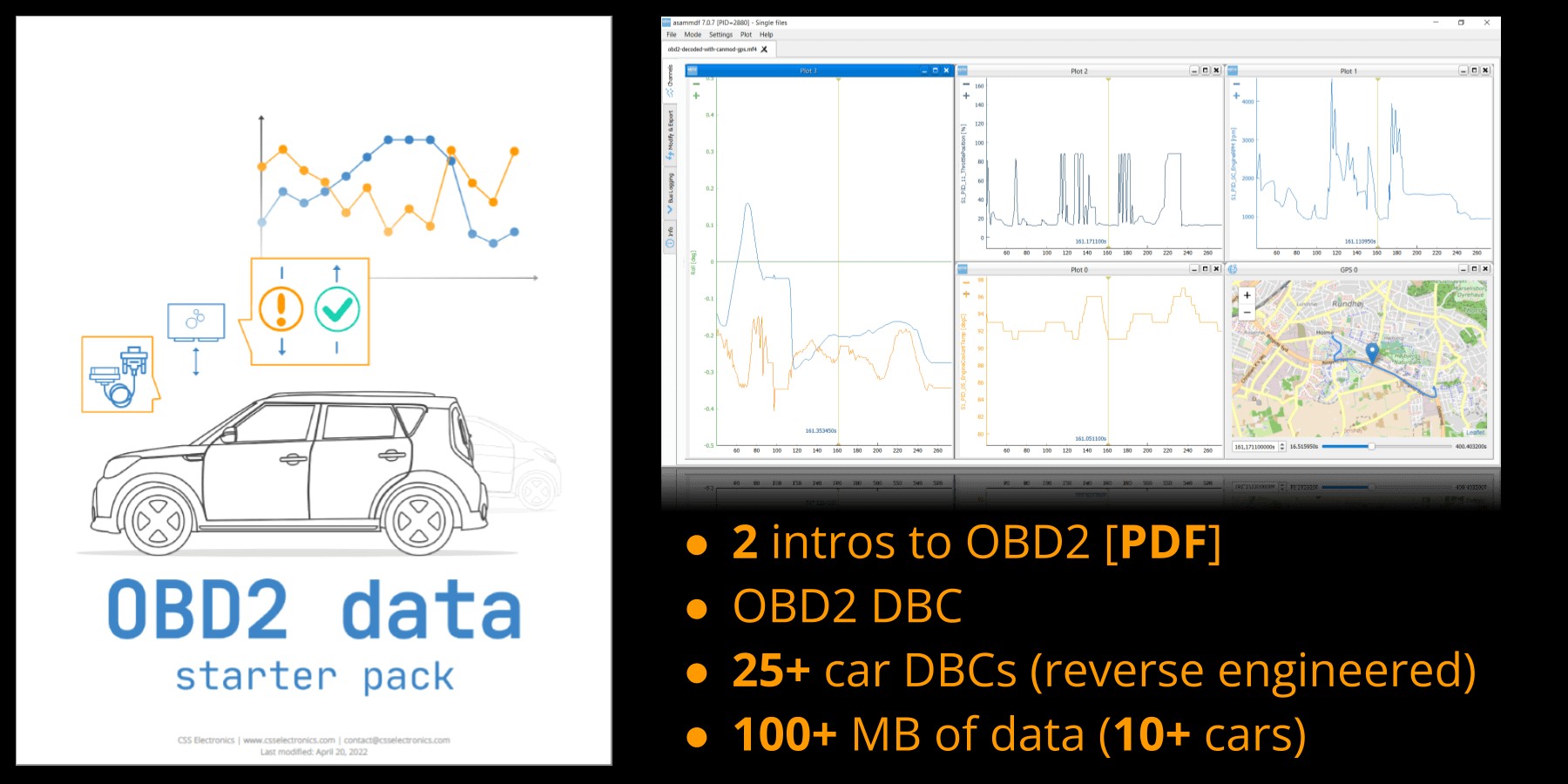

To get hands-on experience with raw OBD2 data, you can download free sample OBD2 data from our CANedge2. You can analyze these MF4 log files using tools like the asammdf GUI and use our OBD2 DBC file to decode the data into a readable format.

Furthermore, our open-source Python API for CAN bus allows you to load and decode raw log files containing CAN/OBD2 data. This API is even used to create OBD2 telematics dashboards using Grafana, giving you powerful visualization capabilities.

DBC CSV Sample Data Software Tools

Download OBD2 data pack with DBC files and sample data for analysis.

Download OBD2 data pack with DBC files and sample data for analysis.

Comprehensive CAN OBD2 PID List (Service 01)

We’ve compiled the following OBD2 PID table to be more user-friendly than some other resources, like the Wikipedia OBD-II PID table. Our table adopts a format similar to CAN databases (DBC files), making it easier to understand the bit start, bit length, scale, and offset needed to extract data from OBD2 PID response frames.

OBD2 uses big endian byte ordering. This means that when you extract bytes from a PID response, you can directly convert the hexadecimal representation to decimal to get the ‘raw_value_decimal’. Then, the actual physical value is calculated using a linear equation, as explained in our DBC introduction.

Let’s take OBD2 PID 0C (Engine Speed) as an example. If you receive an OBD2 response data payload like:

04 41 0C <span>0A 0C</span> AA AA AAThe engine speed data is contained within the bytes 0A 0C (highlighted). Converting the hexadecimal string 0A0C to decimal gives you 2572. To get the engine speed in RPM, you use the formula:

physical_value = offset + scale * raw_value_decimal

Engine Speed (rpm) = 0 + 0.25 * 2572 = 643 rpmThis calculation method applies to most OBD2 PIDs that represent physical values. However, some PIDs are ‘encoded’ and require specific handling. For more details on these, refer to the Wikipedia OBD2 PID overview. This table focuses on OBD2 Service 01 PIDs (current data), which are most relevant for real-time OBD2 data acquisition.

| PID dec | PID hex | Name | Bit start | Bit length | Scale | Offset | Min | Max | Unit |

|—|—|—|—|—|—|—|—|—|

| 0 | 00 | PIDs supported [01 – 20] | 31 | 32 | 1 | 0 | Encoded |

| 1 | 01 | Monitor status since DTCs cleared | 31 | 32 | 1 | 0 | Encoded |

| 2 | 02 | Freeze DTC | 31 | 16 | 1 | 0 | Encoded |

| 3 | 03 | Fuel system status | 31 | 16 | 1 | 0 | Encoded |

| 4 | 04 | Calculated engine load | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 5 | 05 | Engine coolant temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 6 | 06 | Short term fuel trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 7 | 07 | Long term fuel trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 8 | 08 | Short term fuel trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 9 | 09 | Long term fuel trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 10 | 0A | Fuel pressure (gauge pressure) | 31 | 8 | 3 | 0 | 0 | 765 | kPa |

| 11 | 0B | Intake manifold absolute pressure | 31 | 8 | 1 | 0 | 0 | 255 | kPa |

| 12 | 0C | Engine speed | 31 | 16 | 0.25 | 0 | 0 | 16384 | rpm |

| 13 | 0D | Vehicle speed | 31 | 8 | 1 | 0 | 0 | 255 | km/h |

| 14 | 0E | Timing advance | 31 | 8 | 0.5 | -64 | -64 | 64 | deg |

| 15 | 0F | Intake air temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 16 | 10 | Mass air flow sensor air flow rate | 31 | 16 | 0.01 | 0 | 0 | 655 | grams/sec |

| 17 | 11 | Throttle position | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 18 | 12 | Commanded secondary air status | 31 | 8 | 1 | 0 | Encoded |

| 19 | 13 | Oxygen sensors present (2 banks) |

| 20 | 14 | Oxygen sensor 1 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| Oxygen sensor 1 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 21 | 15 | Oxygen sensor 2 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| Oxygen sensor 2 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 22 | 16 | Oxygen sensor 3 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| Oxygen sensor 3 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 23 | 17 | Oxygen sensor 4 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| Oxygen sensor 4 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 24 | 18 | Oxygen sensor 5 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| Oxygen sensor 5 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 25 | 19 | Oxygen sensor 6 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| Oxygen sensor 6 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 26 | 1A | Oxygen sensor 7 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| Oxygen sensor 7 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 27 | 1B | Oxygen sensor 8 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| Oxygen sensor 9 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 28 | 1C | OBD standards the vehicle conforms to | 31 | 8 | 1 | 0 | Encoded |

| 29 | 1D | Oxygen sensors present (4 banks) |

| 30 | 1E | Auxiliary input status |

| 31 | 1F | Run time since engine start | 31 | 16 | 1 | 0 | 0 | 65535 | seconds |

| 32 | 20 | PIDs supported [21 – 40] | 31 | 32 | 1 | 0 | Encoded |

| 33 | 21 | Distance traveled with MIL on | 31 | 16 | 1 | 0 | 0 | 65535 | km |

| 34 | 22 | Fuel rail pres. (rel. to manifold vacuum) | 31 | 16 | 0.079 | 0 | 0 | 5177 | kPa |

| 35 | 23 | Fuel rail gauge pres. (diesel, gas inject) | 31 | 16 | 10 | 0 | 0 | 655350 | kPa |

| 36 | 24 | Oxygen sensor 1 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 1 (voltage) | 47 | 16 | 1/8192 | 0 | 0 | 2 | volts |

| 37 | 25 | Oxygen sensor 2 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 2 (voltage) | 47 | 16 | 1/8192 | 0 | 0 | 8 | volts |

| 38 | 26 | Oxygen sensor 3 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 3 (voltage) | 47 | 16 | 1/8192 | 0 | 0 | 8 | volts |

| 39 | 27 | Oxygen sensor 4 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 4 (voltage) | 47 | 16 | 1/8192 | 0 | 0 | 8 | volts |

| 40 | 28 | Oxygen sensor 5 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 5 (voltage) | 47 | 16 | 1/8192 | 0 | 0 | 8 | volts |

| 41 | 29 | Oxygen sensor 6 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 6 (voltage) | 47 | 16 | 1/8192 | 0 | 0 | 8 | volts |

| 42 | 2A | Oxygen sensor 7 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 7 (voltage) | 47 | 16 | 1/8192 | 0 | 0 | 8 | volts |

| 43 | 2B | Oxygen sensor 8 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 8 (voltage) | 47 | 16 | 1/8192 | 0 | 0 | 8 | volts |

| 44 | 2C | Commanded EGR | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 45 | 2D | EGR Error | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 46 | 2E | Commanded evaporative purge | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 47 | 2F | Fuel tank level input | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 48 | 30 | Warmups since DTCs cleared | 31 | 8 | 1 | 0 | 0 | 255 | count |

| 49 | 31 | Distance traveled since DTCs cleared | 31 | 16 | 1 | 0 | 0 | 65535 | km |

| 50 | 32 | Evap. system vapor pressure | 31 | 16 | 0.25 | 0 | -8192 | 8192 | Pa |

| 51 | 33 | Absolute barometric pressure | 31 | 8 | 1 | 0 | 0 | 255 | kPa |

| 52 | 34 | Oxygen sensor 1 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 1 (current) | 47 | 16 | 1/256 | -128 | -128 | 128 | mA |

| 53 | 35 | Oxygen sensor 2 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 2 (current) | 47 | 16 | 1/256 | -128 | -128 | 128 | mA |

| 54 | 36 | Oxygen sensor 3 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 3 (current) | 47 | 16 | 1/256 | -128 | -128 | 128 | mA |

| 55 | 37 | Oxygen sensor 4 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 4 (current) | 47 | 16 | 1/256 | -128 | -128 | 128 | mA |

| 56 | 38 | Oxygen sensor 5 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 5 (current) | 47 | 16 | 1/256 | -128 | -128 | 128 | mA |

| 57 | 39 | Oxygen sensor 6 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 6 (current) | 47 | 16 | 1/256 | -128 | -128 | 128 | mA |

| 58 | 3A | Oxygen sensor 7 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 7 (current) | 47 | 16 | 1/256 | -128 | -128 | 128 | mA |

| 59 | 3B | Oxygen sensor 8 (air-fuel equiv. ratio) | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| Oxygen sensor 8 (current) | 47 | 16 | 1/256 | -128 | -128 | 128 | mA |

| 60 | 3C | Catalyst temperature (bank 1, sensor 1) | 31 | 16 | 0.1 | -40 | -40 | 6514 | degC |

| 61 | 3D | Catalyst temperature (bank 2, sensor 1) | 31 | 16 | 0.1 | -40 | -40 | 6514 | degC |

| 62 | 3E | Catalyst temperature (bank 1, sensor 2) | 31 | 16 | 0.1 | -40 | -40 | 6514 | degC |

| 63 | 3F | Catalyst temperature (bank 2, sensor 2) | 31 | 16 | 0.1 | -40 | -40 | 6514 | degC |

| 64 | 40 | PIDs supported [41 – 60] | 31 | 32 | 1 | 0 | Encoded |

| 65 | 41 | Monitor status this drive cycle | 31 | 32 | 1 | 0 | Encoded |

| 66 | 42 | Control module voltage | 31 | 16 | 0.001 | 0 | 0 | 66 | V |

| 67 | 43 | Absolute load value | 31 | 16 | 1/2.55 | 0 | 0 | 25700 | % |

| 68 | 44 | Commanded air-fuel equiv. ratio | 31 | 16 | 1/32768 | 0 | 0 | 2 | ratio |

| 69 | 45 | Relative throttle position | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 70 | 46 | Ambient air temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 71 | 47 | Absolute throttle position B | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 72 | 48 | Absolute throttle position C | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 73 | 49 | Accelerator pedal position D | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 74 | 4A | Accelerator pedal position E | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 75 | 4B | Accelerator pedal position F | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 76 | 4C | Commanded throttle actuator | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 77 | 4D | Time run with MIL on | 31 | 16 | 1 | 0 | 0 | 65535 | minutes |

| 78 | 4E | Time since DTCs cleared | 31 | 16 | 1 | 0 | 0 | 65535 | minutes |

| 79 | 4F | Max fuel-air equiv. ratio | 31 | 8 | 1 | 0 | 0 | 255 | ratio |

| Max oxygen sensor voltage | 39 | 8 | 1 | 0 | 0 | 255 | V |

| Max oxygen sensor current | 47 | 8 | 1 | 0 | 0 | 255 | mA |

| Max intake manifold absolute pressure | 55 | 8 | 10 | 0 | 0 | 2550 | kPa |

| 80 | 50 | Max air flow rate from MAF sensor | 31 | 8 | 10 | 0 | 0 | 2550 | g/s |

| 81 | 51 | Fuel type | 31 | 8 | 1 | 0 | Encoded |

| 82 | 52 | Ethanol fuel percentage | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 83 | 53 | Absolute evap system vapor pressure | 31 | 16 | 0.005 | 0 | 0 | 328 | kPa |

| 84 | 54 | Evap system vapor pressure | 31 | 16 | 1 | -32767 | -32767 | 32768 | Pa |

| 85 | 55 | Short term sec. oxygen trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| Short term sec. oxygen trim (bank 3) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 86 | 56 | Long term sec. oxygen trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| Long term sec. oxygen trim (bank 3) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 87 | 57 | Short term sec. oxygen trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| Short term sec. oxygen trim (bank 4) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 88 | 58 | Long term sec. oxygen trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| Long term sec. oxygen trim (bank 4) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 89 | 59 | Fuel rail absolute pressure | 31 | 16 | 10 | 0 | 0 | 655350 | kPa |

| 90 | 5A | Relative accelerator pedal position | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 91 | 5B | Hybrid battery pack remaining life | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 92 | 5C | Engine oil temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 93 | 5D | Fuel injection timing | 31 | 16 | 1/128 | -210 | -210 | 302 | deg |

| 94 | 5E | Engine fuel rate | 31 | 16 | 0.05 | 0 | 0 | 3277 | L/h |

| 95 | 5F | Emission requirements | 31 | 8 | 1 | 0 | Encoded |

| 96 | 60 | PIDs supported [61 – 80] | 31 | 32 | 1 | 0 | Encoded |

| 97 | 61 | Demanded engine percent torque | 31 | 8 | 1 | -125 | -125 | 130 | % |

| 98 | 62 | Actual engine percent torque | 31 | 8 | 1 | -125 | -125 | 130 | % |

| 99 | 63 | Engine reference torque | 31 | 16 | 1 | 0 | 0 | 65535 | Nm |

| 100 | 64 | Engine pct. torque (idle) | 31 | 8 | 1 | -125 | -125 | 130 | % |

| Engine pct. torque (engine point 1) | 39 | 8 | 1 | -125 | -125 | 130 | % |

| Engine pct. torque (engine point 2) | 47 | 8 | 1 | -125 | -125 | 130 | % |

| Engine pct. torque (engine point 3) | 55 | 8 | 1 | -125 | -125 | 130 | % |

| Engine pct. torque (engine point 4) | 63 | 8 | 1 | -125 | -125 | 130 | % |

| 101 | 65 | Auxiliary input/output supported | 31 | 8 | 1 | 0 | Encoded |

| 102 | 66 | Mass air flow sensor (A) | 39 | 16 | 1/32 | 0 | 0 | 2048 | grams/sec |

| Mass air flow sensor (B) | 55 | 16 | 1/32 | 0 | 0 | 2048 | grams/sec |

| 103 | 67 | Engine coolant temperature (sensor 1) | 39 | 8 | 1 | -40 | -40 | 215 | degC |

| Engine coolant temperature (sensor 2) | 47 | 8 | 1 | -40 | -40 | 215 | degC |

| 104 | 68 | Intake air temperature (sensor 1) | 39 | 8 | 1 | -40 | -40 | 215 | degC |

| Intake air temperature (sensor 2) | 47 | 8 | 1 | -40 | -40 | 215 | degC |

| 105 | 69 | Commanded EGR and EGR error |

| 106 | 6A | Com. diesel intake air flow ctr/position |

| 107 | 6B | Exhaust gas recirculation temperature |

| 108 | 6C | Com. throttle actuator ctr./position |

| 109 | 6D | Fuel pressure control system |

| 110 | 6E | Injection pressure control system |

| 111 | 6F | Turbocharger compressor inlet pres. |

| 112 | 70 | Boost pressure control |

| 113 | 71 | Variable geometry turbo control |

| 114 | 72 | Wastegate control |

| 115 | 73 | Exhaust pressure |

| 116 | 74 | Turbocharger RPM |

| 117 | 75 | Turbocharger temperature |

| 118 | 76 | Turbocharger temperature |

| 119 | 77 | Charge air cooler temperature |

| 120 | 78 | EGT (bank 1) |

| 121 | 79 | EGT (bank 2) |

| 122 | 7A | Diesel particulate filter – diff. pressure |

| 123 | 7B | Diesel particulate filter |

| 124 | 7C | Diesel particulate filter – temperature | 31 | 16 | 0.1 | -40 | -40 | 6514 | degC |

| 125 | 7D | NOx NTE control area status |

| 126 | 7E | PM NTE control area status |

| 127 | 7F | Engine run time | seconds |

| 128 | 80 | PIDs supported [81 – A0] | 31 | 32 | 1 | 0 | Encoded |

| 129 | 81 | Engine run time for AECD |

| 130 | 82 | Engine run time for AECD |

| 131 | 83 | NOx sensor |

| 132 | 84 | Manifold surface temperature |

| 133 | 85 | NOx reagent system |

| 134 | 86 | Particulate matter sensor |

| 135 | 87 | Intake manifold absolute pressure |

| 136 | 88 | SCR induce system |

| 137 | 89 | Run time for AECD #11-#15 |

| 138 | 8A | Run time for AECD #16-#20 |

| 139 | 8B | Diesel aftertreatment |

| 140 | 8C | O2 sensor (wide range) |

| 141 | 8D | Throttle position G | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 142 | 8E | Engine friction percent torque | 31 | 8 | 1 | -125 | -125 | 130 | % |

| 143 | 8F | Particulate matter sensor (bank 1 & 2) |

| 144 | 90 | WWH-OBD vehicle OBD system Info | hours |

| 145 | 91 | WWH-OBD vehicle OBD system Info | hours |

| 146 | 92 | Fuel system control |

| 147 | 93 | WWH-OBD counters support | hours |

| 148 | 94 | NOx warning and inducement system |

| 152 | 98 | EGT sensor |

| 153 | 99 | EGT sensor |

| 154 | 9A | Hybrid/EV sys. data, battery, voltage |

| 155 | 9B | Diesel exhaust fluid sensor data |

| 156 | 9C | O2 sensor data |

| 157 | 9D | Engine fuel rate | g/s |

| 158 | 9E | Engine exhaust flow rate | kg/h |

| 159 | 9F | Fuel system percentage use |

| 160 | A0 | PIDs supported [A1 – C0] | 31 | 32 | 1 | 0 | Encoded |

| 161 | A1 | NOx sensor corrected data | ppm |

| 162 | A2 | Cylinder fuel rate | 31 | 16 | 1/32 | 0 | 0 | 2048 | mg/stroke |

| 163 | A3 | Evap system vapor pressure |

| 164 | A4 | Transmission actual gear | 47 | 16 | 0.001 | 0 | 0 | 66 | ratio |

| 165 | A5 | Cmd. diesel exhaust fluid dosing | 39 | 8 | 0.5 | 0 | 0 | 128 | % |

| 166 | A6 | Odometer | 31 | 32 | 0.1 | 0 | 0 | 429496730 | km |

| 167 | A7 | NOx concentration 3, 4 |

| 168 | A8 | NOx corrected concentration (3, 4) |

| 192 | C0 | PIDs supported [C1 – E0] | 31 | 32 | 1 | 0 | Encoded |

This table provides a detailed CAN OBD2 PID list for Service 01, offering essential parameters for vehicle diagnostics and performance monitoring.

Unlock Your Vehicle’s Data Potential

By understanding and utilizing the CAN OBD2 PID list, you gain significant insight into your vehicle’s operation. Whether you’re a car enthusiast, a mechanic, or an automotive engineer, this knowledge empowers you to:

- Diagnose vehicle issues: Access real-time sensor data to pinpoint problems and understand fault codes.

- Monitor vehicle performance: Track parameters like engine speed, temperature, and fuel consumption.

- Develop custom applications: Create your own dashboards, data loggers, or diagnostic tools.

- Gain deeper vehicle understanding: Learn how your vehicle’s systems interact and operate.

We encourage you to explore the provided resources, download our OBD2 data pack, and start experimenting with OBD2 data. For any questions or specific use cases related to OBD2 data logging, feel free to contact us – our experts at carparteu.com are here to assist you!

Further Learning Resources:

- OBD2 Explained – A Simple Intro

- OBD2 Data Logger – Record Your Car Data

- Custom Telematics Dashboards with OBD2 Data

These resources will further enhance your understanding of OBD2 and its applications. Start exploring the power of vehicle data today!