When diagnosing car trouble, an OBD2 scanner is often your first port of call. This invaluable tool plugs into your vehicle’s diagnostic port, allowing you to read trouble codes and access a wealth of data from your car’s computer. But what happens when your OBD2 scanner refuses to communicate? This guide will walk you through the common reasons why you might encounter a “can’t communicate with OBD2” error and provide troubleshooting steps to get you back on track.

Decoding OBD2 Communication Problems

Several factors can prevent your OBD2 scanner from establishing a connection with your vehicle’s computer system. Let’s explore the most frequent culprits:

-

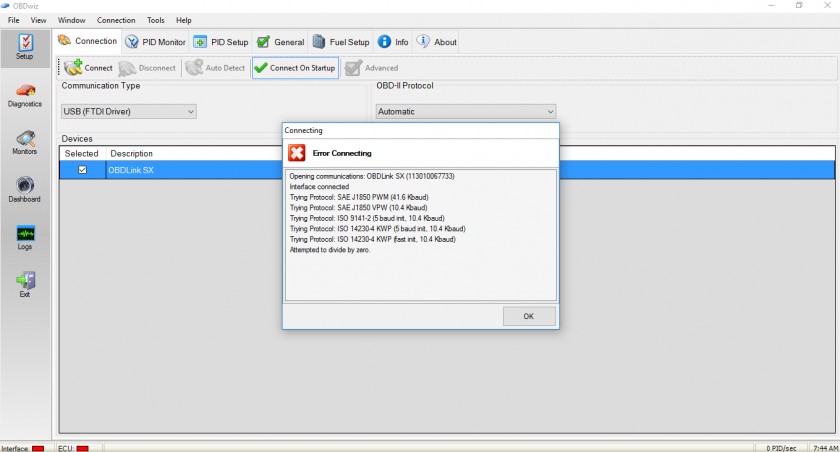

Faulty OBD2 Scanner: The simplest explanation is that the scanner itself is malfunctioning. This could stem from internal hardware problems, software glitches, or even outdated software that’s incompatible with your vehicle. Scanners can fail due to wear and tear, power surges, or manufacturing defects.

-

Damaged OBD2 Port: The OBD2 port in your car, also known as the Diagnostic Link Connector (DLC), is susceptible to damage. Bent or broken pins within the port, corrosion, or physical damage can all disrupt the connection. Sometimes, the port can also become loose or detached from its mounting.

-

Wiring Issues in the OBD2 Circuit: The OBD2 port relies on a network of wires to transmit data between the scanner and your car’s computer (PCM or ECM). Damaged, disconnected, or shorted wires in this circuit will obviously prevent communication. These wiring issues can occur due to rodent damage, age-related wear, or previous repairs.

-

Vehicle Battery Problems: A healthy car battery is crucial for all electrical systems, including the OBD2 system. A dead or significantly low battery may not provide enough power for the OBD2 port and the car’s computer to communicate with the scanner.

-

Blown Fuse Affecting OBD2 Port Power: The OBD2 port, and often the car’s computer, are powered through fuses. A blown fuse in the circuit supplying power to the OBD2 port can cut off power, preventing communication. Sometimes this fuse is shared with the cigarette lighter or other accessories.

Step-by-Step Troubleshooting Guide for OBD2 Communication Failure

If you’re facing the frustration of a scanner that “can’t communicate with OBD2,” follow these diagnostic tests to pinpoint the problem:

TEST 1: Ground Circuit Voltage Drop Test (DLC Pin 4 & 5)

This test checks the integrity of the ground circuits for the OBD2 port.

- Preparation: Set your Digital Multimeter (DMM) to measure DC Voltage.

- Connection: Connect the positive (red) DMM lead to DLC pin 4 (Ground) and the negative (black) DMM lead directly to the negative battery terminal. Use jumper wires if needed to reach the battery terminal directly, ensuring you are NOT connected to the chassis ground.

- Ignition ON: Turn your vehicle’s ignition to the “ON” position (do not start the engine).

- Reading: Observe the voltage reading on the DMM. A healthy ground circuit should show a voltage drop of 0.1 Volts or less.

- Repeat: Repeat this entire process for DLC pin 5 (Signal Ground).

Note: If you measure a voltage drop higher than 0.1V on either pin 4 or 5, it indicates excessive resistance in the ground circuit. This high resistance can prevent the PCM from entering diagnostic mode and communicating with the scanner. Investigate for corroded ground connections or damaged ground wires.

TEST 2: Voltage Check on DLC Pin 16 (Battery Voltage)

This test verifies if the OBD2 port is receiving power from the vehicle’s battery.

- Preparation: Keep your DMM set to measure DC Voltage.

- Connection: Connect the positive (red) DMM lead to DLC pin 16 (Battery Positive) and the negative (black) DMM lead to a known good ground (like the negative battery terminal or DLC pin 4 or 5 which you’ve verified are good grounds in Test 1).

- Ignition ON: Turn your vehicle’s ignition to the “ON” position.

- Reading: The DMM should display approximately the battery voltage (around 12V-14V). If you read significantly lower voltage or no voltage, there’s a power supply issue to the OBD2 port.

TEST 3: Class 2 Serial Data Pin Voltage Check (DLC Pin 2)

Note: This test is generally applicable to vehicles using Class 2 serial data communication protocols but may not be relevant for all vehicle makes and models. Consult your vehicle’s service manual for specific OBD2 communication protocols.

This test checks for signal voltage on the data communication pin.

- Preparation: DMM still set to DC Voltage.

- Connection: Connect the positive (red) DMM lead to DLC pin 2 (Class 2 Serial Data) and the negative (black) lead to a known good ground (DLC pin 4, 5, or battery negative terminal).

- Ignition ON: Turn the ignition to “ON.”

- Reading: You should expect to see approximately 5V or a fluctuating voltage between 3.5V and 5.0V. A steady 0V reading on pin 2 suggests an open circuit in the data communication line, meaning the PCM cannot transmit data to the scanner.

TEST 4: Fuse Check

Locate the fuse box (often under the dashboard or in the engine compartment). Consult your vehicle’s owner’s manual or fuse box diagram to identify the fuse that powers the OBD2 port or the Engine Control Module (ECM) / Powertrain Control Module (PCM). Visually inspect the fuse for a broken filament. Use a fuse tester or DMM in continuity mode to confirm if the fuse is blown. Replace any blown fuses with a fuse of the same amperage rating.

TEST 5: Scanner Self-Test and Alternative Scanner Trial

- Scanner Self-Test: Many OBD2 scanners have a built-in self-test or diagnostic function. Refer to your scanner’s user manual to perform this test and check for any internal scanner errors.

- Try a Different Scanner: If possible, try using a different OBD2 scanner on your vehicle. If a second scanner connects successfully, it strongly indicates that your original scanner is faulty.

Additional Considerations:

- PCM/ECM Issues: In rare cases, a malfunctioning PCM or ECM itself can be the reason for “can’t communicate with OBD2” errors. While less common, if all wiring and power supply tests pass, and multiple scanners fail to connect, a faulty PCM/ECM becomes a possibility.

Fried PCM and OBD2 Communication Failure

Fried PCM and OBD2 Communication Failure

Alt text: Fried PCM preventing OBD2 communication, highlighting the importance of checking PCM in troubleshooting OBD2 scanner connection issues.

- Aftermarket Accessories: Occasionally, aftermarket accessories improperly wired into the vehicle’s electrical system can interfere with OBD2 communication. Try disconnecting any recently installed aftermarket electronics to rule out interference.

Conclusion:

Encountering a “can’t communicate with OBD2” message can be frustrating, but by systematically following these troubleshooting steps, you can effectively diagnose the root cause. Start with the simpler checks like scanner functionality and fuse inspection, then proceed to voltage and ground circuit testing. If you’ve exhausted these steps and are still unable to establish communication, it may be time to consult a qualified automotive technician for further diagnosis and repair, especially if you suspect a PCM/ECM issue. Getting your OBD2 scanner working again is essential for modern vehicle diagnostics and maintenance.