Car air conditioning (AC) systems are essential for driver and passenger comfort, especially during hot weather. While many drivers simply want their AC to work, understanding the components and their functions can be beneficial for maintenance and troubleshooting. This article will delve into the parts of a car AC system, using a car air conditioner diagram to illustrate their connections and roles.

How Car AC Systems Keep You Cool

The fundamental principle behind a car’s AC system is the manipulation of refrigerant between liquid and gaseous states. This process allows the system to absorb heat and humidity from inside the car and release cool, dry air. This transition is achieved by controlling the pressure and temperature of the refrigerant as it circulates through a closed loop system.

Refrigerant Evolution in Car AC Systems

The type of refrigerant used in automotive AC systems has evolved over time due to environmental concerns. Initially, R-12, also known as Freon, was the standard. Freon was effective, non-flammable, and non-poisonous, but it was later discovered to be harmful to the Earth’s ozone layer.

In the mid-1990s, the automotive industry transitioned to R-134a, a hydrofluorocarbon (HFC)-based refrigerant that does not deplete the ozone layer. The latest refrigerant, R-1234yf, is designed to produce fewer greenhouse gases and is increasingly becoming the new global standard, already mandated in Europe. When an AC system loses its cooling efficiency, a technician can recharge it with the appropriate refrigerant.

Key Components: Car Air Conditioner Diagram Parts Explained

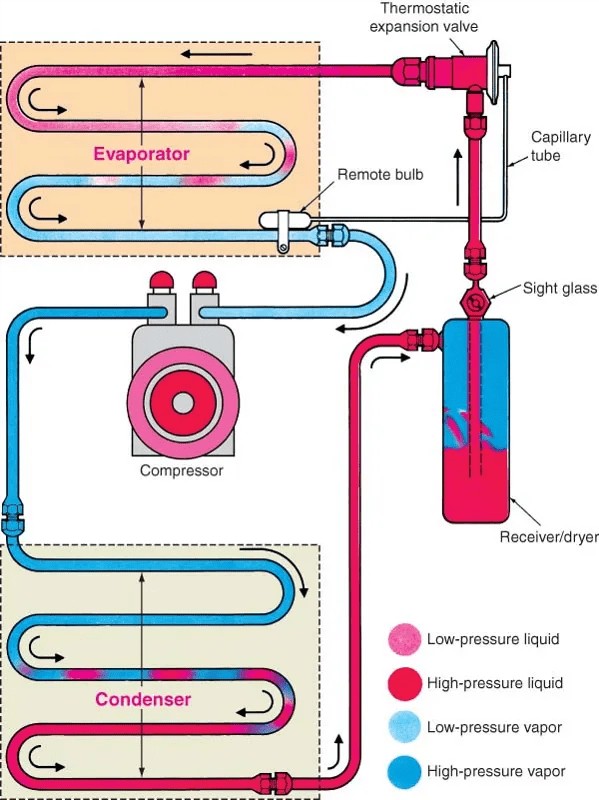

A car AC system comprises several crucial parts, each playing a vital role in the cooling process. A Car Air Conditioner Diagram Parts illustration helps visualize how these components are interconnected. Let’s explore these parts in detail:

Compressor

- Function: The compressor is the heart of the AC system. It acts as a pump, separating the low-pressure side from the high-pressure side.

- Process: It takes in low-pressure, low-temperature refrigerant gas and compresses it into a high-temperature, high-pressure gas.

- Location & Drive: Typically mounted on the engine’s front and driven by the serpentine belt, drawing power from the engine to operate.

Condenser

- Function: The condenser is responsible for reducing the temperature of the high-pressure refrigerant gas discharged from the compressor.

- Process: As the refrigerant cools within the condenser, it transitions from a gaseous state to a high-pressure liquid state, releasing heat in the process.

- Cooling Mechanism & Location: Similar to a radiator, the condenser uses airflow (generated by a fan or vehicle movement) to dissipate heat. It’s usually positioned at the front of the vehicle, behind the grille, to maximize exposure to airflow.

Dryer or Receiver-Drier

- Function: The dryer, also known as a receiver-drier, is crucial for removing moisture from the refrigerant.

- Process: It contains a desiccant, a drying agent that absorbs water, preventing potential damage and ensuring system efficiency. It also provides some filtration to remove contaminants.

- Position: Located on the high-pressure side of the system, between the condenser and the metering device.

Metering Device (Expansion Valve or Orifice Tube)

- Function: The metering device is responsible for reducing the pressure of the liquid refrigerant.

- Process: This pressure drop causes a rapid decrease in the refrigerant’s temperature. The refrigerant remains in liquid form after passing through the metering device but is significantly colder.

- Types & Location: AC systems use either an expansion valve or a fixed orifice tube as the metering device. It’s positioned on the high-pressure side, between the dryer and the evaporator, often near the firewall.

Evaporator

- Function: The evaporator is where the cooling magic happens.

- Process: In the evaporator, the cold, low-pressure liquid refrigerant absorbs heat from the cabin air passing over it, causing the refrigerant to vaporize and change back to a gaseous state. This phase change absorbs significant heat, cooling the air.

- Location & Impact: Uniquely positioned inside the passenger compartment, usually behind the dashboard. Cabin air is cooled and dehumidified as it flows across the evaporator fins, delivering cool, dry air into the vehicle.

Refrigerant Path and State Changes: Visualizing with a Car Air Conditioner Diagram Parts

To understand the complete cycle, tracing the refrigerant path is essential. A car air conditioner diagram parts illustration clearly depicts this flow:

- Compressor Entry: Low-temperature, low-pressure refrigerant enters the compressor as a gas.

- Compressor Exit: High-temperature, high-pressure refrigerant exits the compressor as a gas.

- Condenser Transition: Refrigerant cools in the condenser and changes state to a high-pressure liquid.

- Dryer Filtration: The receiver/dryer removes moisture from the high-pressure liquid refrigerant.

- Metering Device Pressure Drop: The expansion valve or orifice tube reduces the refrigerant pressure.

- Evaporator Cooling: Refrigerant converts back to a low-pressure gas in the evaporator, absorbing heat from the cabin air.

- Cycle Repeats: The low-pressure, low-temperature refrigerant gas returns to the compressor to begin the cycle anew.

Car AC System Diagram

Here’s a visual representation illustrating the car air conditioner diagram parts and their connections:

Car AC System Diagram

Car AC System Diagram

Common Car AC System Problems

Car AC systems are closed and pressurized systems, requiring tight seals to prevent leaks and contamination. Leaks or entry of contaminants are primary causes of AC system failures.

- Refrigerant Leaks: Leaks at any point in the system can lead to refrigerant loss, diminishing cooling performance. Simply recharging the system without fixing the leak is only a temporary solution. Identifying and repairing the leak, often by replacing a faulty component, is crucial before evacuating and recharging the system.

- Compressor Damage: Operating the compressor with insufficient refrigerant due to leaks can cause overheating and internal damage. Compressors are generally not repairable and are a significant replacement expense.

- Condenser Blockage: The condenser, located at the front of the car, is vulnerable to blockage from road debris, dirt, and insects. Reduced airflow through the condenser fins hinders its ability to dissipate heat, leading to system malfunction. Regular inspection and cleaning of the condenser can prevent this issue.

Career Opportunities in Automotive AC Repair

Air conditioning has become a standard feature in almost all new vehicles sold today. This widespread adoption creates a consistent demand for skilled automotive AC technicians. Technicians in dealerships and independent repair shops routinely diagnose and repair AC system issues, addressing customer complaints ranging from warm air and unusual noises to water leaks inside the vehicle. For individuals interested in automotive technology careers, specializing in AC systems offers a valuable and reliable career path.

Car AC System FAQs

How does a car air conditioner work to cool the air?

A car’s AC system uses a compressor to increase the pressure and temperature of the refrigerant. This high-pressure refrigerant then flows through other components, ultimately leading to cooling as the refrigerant evaporates and absorbs heat from the cabin air passing over the evaporator.

What are the main parts shown in a car air conditioner diagram parts illustration?

The primary components are:

- Compressor

- Condenser

- Evaporator

- Receiver-drier (Dryer)

- Expansion valve or Orifice tube (Metering device)

How does refrigerant cool the air inside the car?

The refrigerant, as it passes through the evaporator, changes from a liquid to a gaseous state. This phase change requires heat energy, which is drawn from the air passing over the evaporator. As the refrigerant absorbs heat, the air is cooled and dehumidified before being circulated into the car’s cabin.

Pursue a Career as an Automotive Technician

If a career as an automotive technician appeals to you, consider formal training. Institutions like Universal Technical Institute (UTI) offer comprehensive programs covering all vehicle systems, including advanced air conditioning diagnostics and repair. These programs provide the hands-on skills and theoretical knowledge necessary to enter the automotive service industry.

With training programs that can be completed in less than a year in some cases, you can quickly gain the expertise needed for an entry-level automotive technician position. Visit UTI’s program page for more information and request details to connect with an Admissions Representative.

Automotive Technician Training Campuses

[Start your mechanic or technician career today. Classes begin every 3-6 weeks.]

Hands-on training. Get practical experience with leading industry brands.

No commitment pressure. Get your questions answered without obligation.

Related Resources

How Long Does It Take to Become an Automotive Mechanic?

What Is an Automotive Service Writer and What Do They Do?

The Automotive Technician Shortage: What Does This Mean for Your Career?

UTI Disclosures