Like the human heart, a car engine is the powerhouse of your vehicle. Often referred to as an internal combustion engine, it’s a marvel of engineering that converts fuel into the motion that propels you down the road. While it’s easy to think of the engine as one solid piece, it’s actually a symphony of interconnected components, each playing a vital role in the overall performance.

Understanding the names and functions of these car engine parts is more than just automotive trivia; it’s essential knowledge for car owners. Whether you’re a seasoned mechanic or a curious driver, grasping the basics of engine anatomy can empower you to better maintain your vehicle, diagnose potential issues, and communicate effectively with service professionals.

This guide will take you on a detailed exploration of car engine parts, complete with names and pictures, to enhance your understanding of this critical system. We’ll delve into how these parts work together to bring your car to life, ensuring you’re well-equipped with the knowledge to appreciate and care for your engine.

What Exactly is a Car Engine?

At its core, a car engine is a sophisticated machine designed to transform the chemical energy stored in fuel into mechanical work. This work is then translated into the rotation of your car’s wheels, making movement possible. The magic happens within the engine through a process called internal combustion.

Imagine a precisely controlled series of miniature explosions happening within the engine. These explosions are initiated by a spark that ignites a mixture of fuel vapor and air within a confined space – the cylinder. As this mixture burns rapidly, it expands, generating force. This force is the driving power behind your car.

To handle these intense and repeated bursts of energy, the engine is built to be incredibly robust. Its fundamental structure is composed of two main sections:

- Cylinder Block: This is the heavier, lower portion of the engine. Think of it as the engine’s foundation, housing the main moving parts and providing structural integrity.

- Cylinder Head: This is the detachable upper section that sits atop the cylinder block. It’s a control center, containing passages and valves that manage the intake of air and fuel and the expulsion of exhaust gases after combustion.

Within these primary components, you’ll find other crucial parts:

- Crankshaft: Located in the cylinder block, the crankshaft is the translator of motion. It converts the up-and-down movement of pistons into the rotational motion needed to power the wheels.

- Camshaft: Often housed in the block or cylinder head, the camshaft is the conductor of valve timing. It operates mechanisms that precisely open and close the valves in the cylinder head, controlling the flow of air and exhaust.

How a Car Engine Converts Fuel to Motion

Think of your body converting food into energy – a car engine performs a similar feat, but with gasoline. This conversion process is known as “internal combustion,” where the burning of fuel occurs inside the engine itself.

Here’s a simplified breakdown:

- Fuel and Air Mix: Gasoline is mixed with air.

- Combustion: This mixture is ignited and burns rapidly, creating expanding gases.

- Piston Movement: These expanding gases push against a movable component called a piston.

- Crankshaft Rotation: The piston’s linear motion is converted into rotational motion by the crankshaft.

- Power to Wheels: This rotational motion is then transmitted through the powertrain (gear system) to the wheels, propelling the vehicle.

Imagine a tiny, contained explosion pushing a piston repeatedly. A typical car engine performs hundreds of these explosions every minute, harnessing the released energy to move your car.

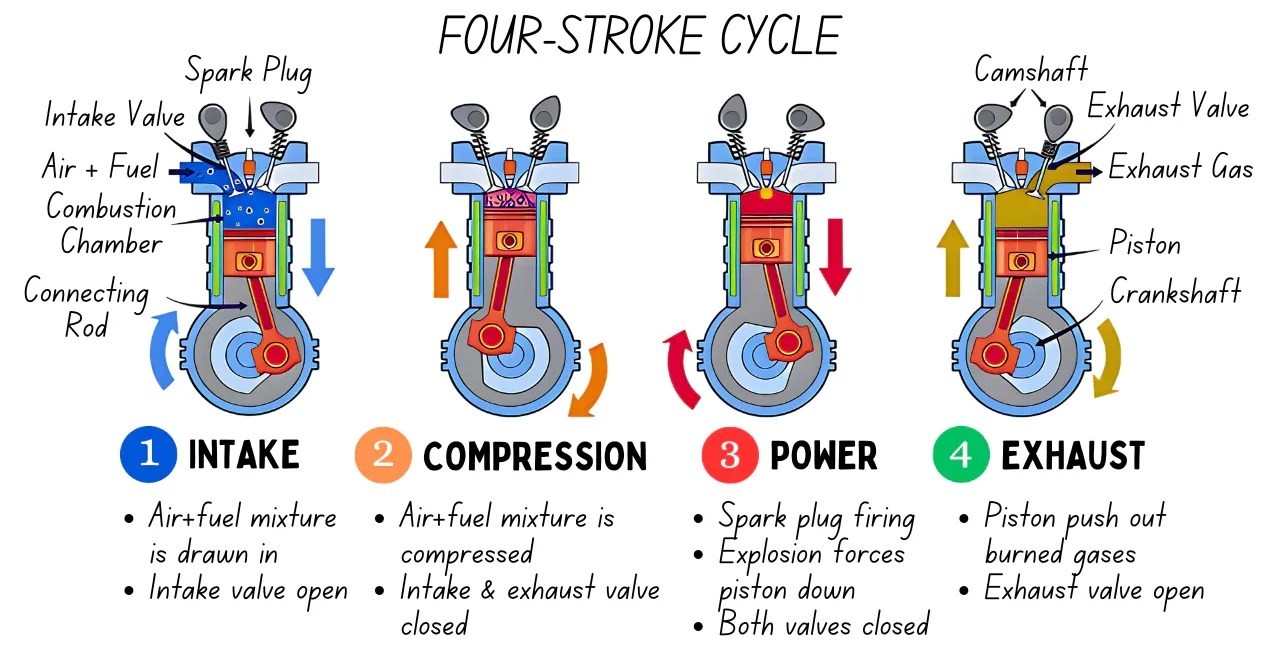

This process is precisely orchestrated through the four-stroke combustion cycle, the heartbeat of most car engines. These four strokes – intake, compression, combustion (power), and exhaust – repeat continuously to generate power. Let’s examine each stroke in detail:

1. Intake Stroke

- The piston travels downwards within the cylinder.

- The intake valve opens, while the exhaust valve remains closed.

- This downward movement creates a vacuum, drawing the air-fuel mixture into the cylinder through the open intake valve, much like inhaling air into your lungs.

2. Compression Stroke

- The piston now moves upwards in the cylinder.

- Both intake and exhaust valves are tightly closed.

- The upward motion compresses the air-fuel mixture into a much smaller space, the combustion chamber, increasing its temperature and preparing it for ignition.

3. Power Stroke (Combustion)

- The spark plug ignites the highly compressed air-fuel mixture with a precisely timed spark.

- This ignition causes rapid combustion, generating immense pressure that forces the piston downwards with great force.

- This downward force rotates the crankshaft, providing the engine’s power and propelling the vehicle forward. Both valves remain closed during this powerful stroke.

4. Exhaust Stroke

- The piston moves upwards again.

- The exhaust valve opens, while the intake valve stays closed.

- The upward movement pushes the spent exhaust gases out of the cylinder through the open exhaust valve, clearing the way for the next intake stroke. These gases are then treated by the catalytic converter and muffled before exiting through the tailpipe.

This four-stroke cycle repeats continuously and in rapid succession in each cylinder of the engine. In multi-cylinder engines, these cycles are carefully timed and staggered to ensure smooth and balanced operation, minimizing vibrations and noise.

It’s important to note that gasoline engines are not perfectly efficient. Typically, only about 20% of the fuel’s chemical energy is converted into mechanical energy, and of that, only around 15% actually reaches the wheels. The rest is lost as heat, friction, and through other mechanical inefficiencies.

Now, let’s dive into the specific parts that make this intricate process possible. You might recognize some car engine parts names already, but understanding their roles and interactions is key to appreciating the engineering marvel beneath your car’s hood.

Car Engine Parts Names with Diagram: A Visual Guide

To get a clear picture of where each part is located, let’s look at a car engine parts diagram. This visual representation will help you understand the spatial relationships between different components and how they fit into the engine as a whole.

As you can see in the diagram, a car engine is a complex assembly of parts. Some of the key components you can identify include:

- Engine Block

- Combustion Chamber

- Cylinder Head

- Pistons

- Crankshaft

- Camshaft

- Timing Chain or Belt

- Valves

- Rocker Arms

- Pushrods/Lifters

- Fuel Injectors

- Spark Plugs

- Oil Pan

- Distributor (in older vehicles)

- Connecting Rods

- Piston Rings

- Flywheel

This diagram offers a great overview, but let’s now explore a more comprehensive list of car engine parts names.

Comprehensive List of Car Engine Parts Names

While the diagram gives us a visual, a list provides a more complete picture of the numerous components within a car engine. Remember, even though we often think of the engine as one unit, it’s actually a collection of individual parts working in perfect synchronization.

Here is an expanded list of car engine parts names:

- Distributor O-ring

- Cylinder Head Cover

- Rubber Grommet

- Camshaft Pulley

- Oil Filter

- Water Pump

- Timing Belt Drive Pulley

- Oil Pan Drain Bolt

- Turbocharger and Supercharger (for forced induction engines)

- Starter Motor

It’s fascinating to consider that a typical internal combustion engine can have around 200 individual parts! Maintaining and potentially replacing these parts as they wear is crucial for engine longevity. In contrast, electric vehicles boast significantly fewer moving parts in their motors, often around 20, highlighting the complexity of the internal combustion engine.

For our detailed exploration, however, we will focus on the main parts of a car engine – the components that are most fundamental to its operation and understanding.

Key Parts of a Car Engine: Functions and Details

Let’s delve deeper into the function of each key car engine part. Understanding what each component does and how it contributes to the overall engine operation will give you a much richer understanding of your vehicle’s inner workings.

1. Engine Block (Cylinder Block)

Engine Block Component: A close-up view of an engine block, showcasing its robust structure designed to house the engine’s core moving parts and cylinders.

The engine block, also known as the cylinder block, is the foundational structure of the engine. It’s the core component that houses and supports all the major engine parts, forming the “bottom end” of the engine.

- Houses Cylinders: The engine block contains the cylinders, the hollow chambers within which the pistons move.

- Crankshaft Housing: It provides the main bearings that support the crankshaft, allowing it to rotate smoothly.

- Camshaft Housing (sometimes): In some engine designs, the engine block also houses the camshaft.

- Material: Modern engine blocks are often made of lightweight aluminum, while older vehicles and heavy-duty trucks may use cast iron for its durability.

- Cooling and Lubrication Passages: The block has intricate channels for coolant and oil to flow, crucial for engine cooling and lubrication. Water passages are wider for effective heat dissipation, while oil passages are designed for lubrication of moving parts.

When the cylinder head is bolted to the top of the engine block, it seals the cylinders, creating the combustion chambers. The pistons move up and down within these cylinders, driven by combustion, and their motion rotates the crankshaft, ultimately powering the wheels. The oil pan sits at the base of the engine block, serving as a reservoir for engine oil.

Common Symptoms of a Failing Engine Block:

- Poor Engine Performance: Low compression due to block damage can lead to reduced power.

- Visible Engine Smoke: Cracks can allow oil or coolant to burn, resulting in smoke.

- Engine Overheating: Leaks in the block can cause coolant loss and overheating.

- Discolored Oil or Coolant: Mixing of fluids due to block damage can cause discoloration.

- Oil or Coolant Leaks: External leaks can be a sign of cracks or damage.

- Frozen Coolant: In cold climates, block cracks can lead to coolant freezing and expansion damage.

- Excessive Exhaust Smoke: Burning coolant or oil can produce noticeable smoke.

- Low Coolant Levels: Leaks from the block will cause coolant levels to drop.

2. Piston

Car Piston Component: A detailed image of a car piston, highlighting its structure and rings, essential for converting combustion pressure into mechanical force.

Pistons are cylindrical components that move up and down inside the cylinders. They are the direct recipients of the force generated by combustion, converting this pressure into motion.

- Motion Conversion: Pistons transform the pressure from burning fuel into a linear force acting on the crankshaft.

- Shape and Material: Piston design varies depending on engine type. Gasoline engine pistons are typically lighter and shorter than diesel pistons. They are usually made of aluminum alloys for strength and heat resistance.

- Piston Assembly: Each piston is connected to the crankshaft via a connecting rod. The connection is made by a wrist pin (or gudgeon pin), a hollow tube that bears the brunt of combustion force. This assembly is known as the piston assembly.

- Piston Rings: To seal the narrow gap between the piston and cylinder wall, piston rings are used. These rings fit into grooves on the piston and prevent combustion gases from escaping and oil from entering the combustion chamber. The areas between these grooves are called ring lands.

Pistons endure incredibly rapid motion, moving up and down twice for every crankshaft revolution. In an engine running at 1300 RPM, a piston moves up and down 2600 times per minute!

Functions of a Piston:

- Heat Dissipation: Helps transfer heat away from the combustion chamber.

- Combustion Chamber Sealing: Prevents gas leakage and oil contamination of the combustion chamber.

- Connecting Rod Guidance: Guides the movement of the connecting rod.

- Gas Exchange: Facilitates continuous gas exchange within the combustion chamber.

- Variable Volume Creation: Creates the changing volume of the combustion chamber during the four-stroke cycle.

Common Symptoms of Bad Pistons:

- White or Gray Exhaust Smoke: Burning oil due to piston ring or piston damage can cause this.

- Excessive Oil Consumption: Oil leaking past damaged piston rings increases oil usage.

- Low Power for Acceleration: Reduced compression from piston issues weakens engine power.

- Overall Loss of Power or Poor Performance: Inefficient combustion due to piston problems degrades performance.

3. Crankshaft

Crankshaft Engine Part: An image of a crankshaft, showcasing its journals and throws that convert reciprocating piston motion into rotary motion to power the vehicle.

The crankshaft is the backbone of the internal combustion engine. It’s the crucial component that converts the linear, up-and-down motion of the pistons into the rotational motion needed to drive the wheels.

- Motion Conversion: Transforms reciprocating piston motion into rotary motion.

- Location: Situated in the crankcase, below the engine block.

- Material: Typically made of strong steel to withstand high stresses. Often forged as a single piece for maximum strength.

- Bearings and Connections: The crankshaft is supported at both ends by large bearings within the engine block. It connects to the flywheel and subsequently to the clutch (in manual transmissions) or torque converter (in automatic transmissions).

When the clutch is engaged, the crankshaft’s rotational energy is transmitted through the gearbox, differential, and drive shafts to the wheels, propelling the car.

Symptoms of a Bad or Failing Crankshaft Position Sensor (Note: This is related to crankshaft function, not crankshaft failure itself):

- Issues Starting the Vehicle: Sensor failure can disrupt ignition timing.

- Intermittent Stalling: Faulty sensor signals can cause the engine to stall unexpectedly.

- Check Engine Light: Sensor problems often trigger the check engine light.

- Uneven Acceleration: Inconsistent crankshaft position readings can lead to jerky acceleration.

- Engine Misfires or Vibrates: Incorrect timing can cause misfires and vibrations.

- Rough Idle and/or Vibrating Engine: Sensor issues can affect idle stability.

- Reduced Gas Mileage: Inefficient combustion due to timing problems can lower fuel economy.

4. Camshaft

Engine Camshaft Part: A camshaft image highlighting its lobes, which precisely control the opening and closing of engine valves to regulate air and fuel flow.

The camshaft is a rotating shaft with strategically shaped protrusions called cams or cam lobes. Its primary function is to control the opening and closing of the engine’s valves at precisely timed intervals.

- Valve Control: Cams act on valves, opening them to a degree proportional to the cam lobe’s shape. The camshaft’s rotation speed dictates valve operation speed.

- Valve Timing: Camshafts precisely control when intake valves open to allow air-fuel mixture entry and when exhaust valves open to expel combustion gases. This timing is crucial for engine performance and efficiency.

- Location: In modern engines, camshafts are often located directly above the cylinder banks in the cylinder head (overhead camshaft – OHC designs).

- Connection to Crankshaft: The camshaft’s rotation is synchronized with the crankshaft’s rotation via a timing belt or timing chain. This ensures that valve timing is precisely coordinated with piston movement.

- Material: Camshafts are made of strong metals like chilled iron for durability.

The shape and profile of the cams are carefully designed to optimize engine performance characteristics, such as power and fuel efficiency. Camshaft design directly influences the engine’s power band and overall performance.

Symptoms of a Bad Camshaft:

- Active or Flashing Check Engine Light: Camshaft sensor or timing issues can trigger the light.

- Loss of Power: Worn cams can lead to improper valve timing and reduced power.

- Steady Popping/Backfire: Extreme cam wear can cause backfiring in the intake or exhaust.

- Loud Ticking or Tapping Sounds: Worn cams or lifters can create valve train noise.

- Metal Debris in Engine Oil: Camshaft wear can shed metal particles into the oil.

- Cylinder Misfire: Incorrect valve timing can cause misfires in specific cylinders.

- Increased Emissions: Misfires due to cam issues can increase harmful emissions.

- Visible Signs of Damage: Inspecting the camshaft may reveal wear or damage to the lobes.

5. Connecting Rod

Engine Connecting Rod Part: A connecting rod image illustrating its role in linking the piston to the crankshaft, converting piston stroke into crankshaft rotation.

The connecting rod is, as its name suggests, the link between the piston and the crankshaft. It transmits the force from the piston to the crankshaft, enabling the conversion of linear piston motion into rotary crankshaft motion.

- Piston-Crankshaft Link: Connects the piston to the crankshaft, forming a crucial part of the power transmission system.

- Material: Usually made of steel or aluminum, chosen for strength and lightness.

- Rod Ends: The end connected to the piston is called the small end, and the end connected to the crankshaft is the big end.

- Bearing Inserts: The big end incorporates bearing inserts to minimize friction and maintain precise oil clearance with the crankshaft journal.

- Connecting Rod Cap: The big end is split and uses a connecting rod cap to clamp around the crankshaft journal and secure the bearing.

The connecting rod experiences both compressive and tensile forces as it transmits power. Its design allows for pivoting at the piston end and rotation at the crankshaft end. Some connecting rods have an oil passage to spray oil onto the cylinder wall for lubrication.

Symptoms of a Bad Connecting Rod:

- Low Compression: Bent or damaged rods can affect piston movement and compression.

- Engine Knocking Sounds (Rod Knock): Worn or damaged connecting rod bearings create a distinct knocking sound, especially under load.

- Low Oil or Oil Pressure: Rod knock can be associated with oil pressure issues.

- Visibly Bent or Damaged Rod: In severe cases, rod damage may be visible upon engine inspection.

- Seized Engine: Catastrophic rod failure can lead to engine seizure.

6. Timing Belt or Timing Chain

Timing Belt Engine Part: A timing belt image showing its toothed design, crucial for synchronizing crankshaft and camshaft rotation for precise engine timing.

The timing belt or timing chain is a critical component that synchronizes the rotation of the crankshaft and camshaft(s). This synchronization is essential for proper engine operation, ensuring that valves open and close in perfect coordination with piston movement.

- Synchronization: Connects the crankshaft and camshaft(s), maintaining precise timing between them.

- Combustion Cycle Coordination: Ensures the engine’s combustion cycle is properly timed, controlling valve and piston interaction.

- Valve and Piston Clearance: Prevents pistons from colliding with valves by ensuring they operate in sync.

- Material: Modern timing belts are typically made of durable synthetic rubber materials like neoprene or polyurethane, reinforced with high-tensile cords like Kevlar or fiberglass. Timing chains are made of metal.

- Maintenance: Timing belts have a service life and typically need replacement every 60,000 to 100,000 miles, as recommended by the vehicle manufacturer. Timing chains generally last longer but can also wear or stretch over time.

A worn timing belt or chain can slip, causing engine misfires or even catastrophic engine damage if the timing is severely disrupted and valves collide with pistons (in interference engines).

Symptoms of a Bad Timing Belt or Chain:

- Ticking Noise from Engine: A worn belt or chain can create ticking sounds.

- Engine Won’t Turn Over: A broken timing belt or chain can prevent the engine from turning.

- Engine Acts Up Between 2,000-4,000 RPM: Slipping belts can cause performance issues in this RPM range.

- Engine Misfires: Timing misalignment causes misfires.

- More Smoke and Fumes than Normal: Inefficient combustion due to timing issues can increase emissions.

- Oil Leaks from Front of Motor: Timing cover seal leaks can sometimes be associated with timing belt/chain issues.

7. Spark Plug

Spark Plug Engine Component: Spark plugs are shown, illustrating their role in igniting the air-fuel mixture in the combustion chamber to initiate the power stroke.

Spark plugs are essential ignition components located in the cylinder head, above each cylinder. They are responsible for initiating combustion by creating a spark that ignites the air-fuel mixture in the combustion chamber.

- Ignition Source: Convert high-voltage electricity into a spark within the combustion chamber.

- Combustion Initiation: The spark ignites the compressed air-fuel mixture just before the power stroke, initiating combustion.

- Construction: A spark plug consists of a threaded metal sleeve, a ceramic insulator, and a center electrode. The center electrode is connected to the ignition coil, and the metal housing is grounded to the cylinder head. A spark gap exists between the center electrode and the side electrode.

- Wear and Fouling: Spark plugs can degrade over time due to wear, combustion byproducts, contamination, or overheating.

Fouled or worn spark plugs can lead to various engine performance issues.

Symptoms of Bad Spark Plugs:

- Reduced Gas Mileage: Inefficient combustion due to weak spark lowers fuel economy.

- Lack of Acceleration: Misfires caused by bad plugs reduce power and acceleration.

- Hard Starts: Weak spark makes it difficult to start the engine, especially in cold conditions.

- Engine Misfires: Misfires are a common symptom of failing spark plugs.

- Rough Idling: Uneven combustion due to spark plug issues causes rough idling.

8. Cylinder Head

Cylinder Head Engine Part: A cylinder head image showing its complex structure that houses valves, camshafts, spark plugs, and fuel injectors, sealing the top of the cylinders.

The cylinder head sits atop the engine block, sealing the cylinders and forming the upper part of the combustion chambers. It’s a complex component that houses many critical engine elements.

- Combustion Chamber Sealing: Seals the top of the cylinders, creating the combustion chamber when combined with the piston and cylinder walls.

- Houses Valves: Contains intake and exhaust valves that control airflow into and out of the cylinders.

- Camshaft Housing (OHC engines): In overhead camshaft (OHC) engines, the cylinder head houses the camshaft(s).

- Spark Plug and Injector Location: Provides locations for spark plugs (gasoline engines) and fuel injectors.

- Coolant Passages: Contains coolant passages for engine cooling.

- Material: Cylinder heads are made of cast iron or aluminum. Aluminum heads are lighter and offer better heat dissipation, while cast iron heads are more durable and less expensive.

Cylinder heads must withstand high pressures and temperatures. Overheating is a common cause of cylinder head damage, leading to cracks or warping.

Symptoms of a Cracked Cylinder Head:

- White Smoke (Steam) from Exhaust Pipe: Coolant leaking into cylinders burns and creates white smoke.

- Low Coolant Level: Coolant leaks from a cracked head reduce coolant levels.

- Engine Overheating: Coolant loss and compromised cooling can cause overheating.

- Rough Running and Misfiring: Coolant or compression leaks affect combustion.

- Combustion Gases in Cooling System: Leaks can allow combustion gases to enter the coolant.

- Illuminated Warning Lights: Overheating or other issues may trigger warning lights.

- Coolant-Oil Intermix: Cracks can allow coolant and oil to mix, resulting in a milky appearance in either fluid.

9. Oil Pan

Car Oil Pan Part: An oil pan image showing its location at the bottom of the engine, serving as a reservoir for engine oil and featuring a drain plug for oil changes.

The oil pan is located at the bottom of the engine, bolted to the underside of the engine block. It serves as the reservoir for engine oil.

- Oil Reservoir: Holds the engine oil when it’s not circulating through the engine.

- Oil Supply: Provides oil for the oil pump to draw from and circulate for lubrication and cooling.

- Drain Plug: Equipped with a drain plug at the bottom for easy oil draining during oil changes.

- Material: Typically made of steel or aluminum.

- Capacity: Oil pans typically hold 4 to 6 liters of oil, depending on engine size.

- Dipstick: The oil dipstick extends into the oil pan to measure the oil level.

The oil pan ensures a ready supply of oil for the engine’s lubrication system, which is vital for reducing friction and wear.

Symptoms of a Bad Oil Pan:

- Low Oil Warning Light: Low oil level due to a leak will trigger the warning light.

- Puddle of Oil Under Car: Leaks from the oil pan will leave oil puddles.

- Unexpectedly Dropped Oil Level: Leaks cause a sudden drop in oil level.

- Engine Overheating: Oil loss due to a leak can lead to insufficient lubrication and overheating.

- Burning Smell from Engine: Oil leaking onto hot engine parts can cause a burning smell.

10. Engine Valves

Engine Valves Component: Engine valves are displayed, highlighting their role in controlling the intake of air and fuel and the exhaust of combustion gases in a car engine.

Engine valves are mechanical components that control the flow of air and fuel into the combustion chambers and the expulsion of exhaust gases. They open and close at precise times, dictated by the camshaft, to regulate the engine’s breathing.

- Flow Control: Regulate the intake of air-fuel mixture and the exhaust of combustion gases.

- Intake Valves: Allow air and fuel to enter the combustion chamber.

- Exhaust Valves: Allow exhaust gases to exit the combustion chamber.

- Valve Train: Valves are operated by the valve train, which includes camshafts, rocker arms, pushrods (in some designs), and valve springs.

- Valve Timing: Valve opening and closing are precisely timed by the camshaft to match the four-stroke cycle.

Valves must seal tightly when closed to maintain compression in the combustion chamber. Worn or damaged valves can lead to compression leaks and performance issues.

Symptoms of Bad Valves:

- Poor Performance When Cold: Valve sealing issues can be more pronounced when the engine is cold.

- Off-Throttle Braking Issues: Valve problems can affect engine braking.

- Rough Idling: Improper valve sealing can cause uneven idling.

- Excessive Oil Consumption: Worn valve seals can allow oil to leak into the combustion chamber.

- Excessive Smoke: Burning oil due to valve seal leaks can produce smoke.

- Loss of Engine Power: Compression leaks from valve problems reduce power.

11. Combustion Chamber

Combustion Chamber Engine Part: A combustion chamber is depicted, showing the space where the air-fuel mixture is burned, generating high-pressure gases to power the engine.

The combustion chamber is the confined space within the cylinder where the air-fuel mixture is burned. It’s formed by the cylinder head, cylinder walls, and piston top when the piston is at its top dead center (TDC).

- Combustion Zone: The area where the air-fuel mixture ignites and burns, releasing energy.

- High Pressure and Temperature: Combustion generates high pressure and temperature gases.

- Piston Movement: The expanding gases push the piston, converting thermal energy into mechanical energy.

- Compression Ratio: The size and shape of the combustion chamber influence the engine’s compression ratio. Smaller chambers generally lead to higher compression and more power but also higher temperatures.

Oil entering the combustion chamber can cause blue-gray exhaust smoke. This can happen due to worn valve seals or piston rings.

What happens if oil gets into the combustion chamber?

Oil burning in the combustion chamber results in blue-grey exhaust smoke. This is often caused by worn valve seals or piston rings, allowing oil to leak into the combustion chamber.

12. Intake Manifold

Intake Manifold Engine Component: An intake manifold is shown, illustrating its runners and plenum, which distribute air evenly to each of the engine’s cylinders for combustion.

The intake manifold is a component that distributes air (or air-fuel mixture in some older designs) to the engine’s cylinders. In many modern cars, it also houses the fuel injectors.

- Air Distribution: Channels air from the throttle body to each cylinder’s intake port.

- Fuel Injector Housing: In many engines, the intake manifold provides mounting locations for fuel injectors.

- Components: Consists of a plenum (a chamber that receives air) and runners (tubes that distribute air to each cylinder).

- Performance Tuning: Intake manifold design (plenum size, runner length and diameter) can be optimized to influence engine performance characteristics. Variable intake manifolds are used in modern cars to optimize airflow at different engine speeds.

Problems with the intake manifold are relatively rare, but leaks or damage can affect engine performance. Some diesel engines have swirl flaps in the intake manifold that can become problematic.

Symptoms of a Bad Intake Manifold:

- Check Engine Light: Manifold leaks or sensor issues can trigger the light.

- Misfires: Vacuum leaks in the manifold can cause lean air-fuel mixtures and misfires.

- Rough Idle: Uneven air distribution can lead to rough idling.

- Loss in Engine Performance: Air leaks or restricted airflow reduce engine power.

- External Coolant Leaks: Some manifolds have coolant passages and can leak.

- Engine Overheating: Coolant leaks from the manifold can contribute to overheating.

13. Exhaust Manifold

Exhaust Manifold Engine Part: An exhaust manifold is shown, designed to collect exhaust gases from multiple cylinders into a single pipe, directing them towards the exhaust system.

The exhaust manifold collects exhaust gases from multiple cylinders and directs them into the exhaust system, typically towards the catalytic converter.

- Exhaust Gas Collection: Collects hot exhaust gases from each cylinder’s exhaust port.

- Directs Gases to Exhaust System: Channels exhaust gases towards the catalytic converter and the rest of the exhaust system.

- Turbocharger Mounting (Turbo Engines): In turbocharged engines, the turbocharger is often mounted directly to the exhaust manifold to utilize exhaust gas energy.

- Material: Exhaust manifolds are made of tubular steel, stainless steel, or cast iron to withstand high temperatures.

- Oxygen Sensor Location: Exhaust manifolds often have a location for the oxygen sensor, which monitors exhaust gas composition.

Leaks in the exhaust manifold or its gasket can be dangerous, allowing hot exhaust gases to escape and potentially enter the cabin. They can also cause oxygen sensor errors and trigger the check engine light.

Symptoms of a Cracked or Bad Exhaust Manifold:

- Check Engine Light: Exhaust leaks can affect oxygen sensor readings and trigger the light.

- Burning Smells: Escaping exhaust gases can create a burning smell.

- Performance Problems or Sluggish Acceleration: Exhaust leaks can affect engine performance.

- Poor Fuel Economy: Inefficient combustion due to exhaust leaks can reduce fuel economy.

- Loud Exhaust Noise: Cracks or leaks in the manifold can cause a noticeable increase in exhaust noise.

- Visible Damage: Cracks or rust may be visible upon inspection.

14. Piston Ring

Piston Ring Engine Component: Piston rings are displayed, showing their function in sealing the combustion chamber, controlling oil, and transferring heat from the piston to the cylinder wall.

Piston rings are metallic split rings that fit into grooves on the piston’s outer diameter. They are crucial for sealing the combustion chamber and controlling oil consumption.

- Sealing: Create a seal between the piston and cylinder wall, preventing combustion gases from escaping into the crankcase (blow-by).

- Oil Control: Scrape excess oil from the cylinder walls, preventing it from entering the combustion chamber and burning.

- Heat Transfer: Help transfer heat from the piston to the cylinder walls for cooling.

- Wear Control: Contribute to wear resistance between the piston and cylinder wall.

- Material: Typically made of cast iron.

A typical car engine piston has multiple rings per piston, usually two compression rings and one oil control ring.

Symptoms of Bad Piston Rings:

- Discolored or Excessive Exhaust Smoke: Worn rings allow oil to burn, causing blue smoke.

- Oil Leaks or Profuse Oil Consumption: Oil bypasses worn rings and is consumed in combustion.

- Declining Engine Performance: Compression loss from worn rings reduces power.

- Low Acceleration: Reduced compression weakens acceleration.

- Oil in the Intake Manifold: Blow-by gases containing oil can enter the intake.

15. Gudgeon Pin (Wrist Pin)

The gudgeon pin, also known as a wrist pin, connects the piston to the connecting rod. It provides a pivot point for the connecting rod as the piston moves.

- Piston-Connecting Rod Joint: Connects the piston to the connecting rod, allowing for relative motion between them.

- Bearing Surface: Provides a bearing surface for the connecting rod to pivot on.

- Material: Made of high-strength, hardened alloy steel.

16. Cam

Engine Cam Part: A cam lobe on a camshaft is shown, emphasizing its specially shaped profile that dictates the timing and extent of valve opening and closing.

A cam is a shaped lobe on a rotating shaft (camshaft). It’s used to convert rotary motion into linear motion, specifically to actuate engine valves.

- Rotary to Linear Motion Conversion: Camshaft rotation is converted into the linear motion of valve actuation.

- Valve Timing Control: Cam shape dictates the timing and lift (extent of opening) of engine valves.

- Engine Performance Influence: Camshaft profile and cam design significantly affect engine performance characteristics.

17. Flywheel

Flywheel Engine Part: A flywheel is shown, a heavy wheel attached to the crankshaft, designed to smooth engine rotation and store rotational energy for smoother operation.

The flywheel is a heavy wheel attached to the crankshaft. It helps smooth out engine rotation and store rotational energy.

- Smooth Engine Rotation: Reduces engine vibration and noise by smoothing out the pulses of power from combustion strokes.

- Inertia and Momentum: Stores rotational energy, providing momentum to help the crankshaft rotate between power strokes and during engine starting.

- Engine Starting Aid: Helps the starter motor turn the engine over for starting.

- Material: Typically made of cast iron or steel.

Without a flywheel, the engine’s power delivery would be very jerky, and starting would be much more difficult.

Symptoms of a Bad Flywheel:

- Slipping Gears: Flywheel issues can cause clutch slippage in manual transmissions.

- Cannot Change Gears: Difficulty shifting gears can be a sign of flywheel problems.

- Burning Odor: Clutch slippage due to flywheel issues can cause a burning smell.

- Clutch Vibrations (Clutch Chatter): Uneven flywheel surface can cause clutch vibrations.

- Unable to Start or Inconsistent Starts: Flywheel problems can affect engine starting.

- Engine Stalling: Rough flywheel rotation can lead to engine stalling.

- Engine Vibrations with Clutch Engaged: Vibrations felt when the clutch is engaged can indicate flywheel issues.

18. Head Gasket

Head Gasket Engine Part: A head gasket is shown, designed to seal the engine block and cylinder head, preventing leaks of combustion gases, coolant, and oil.

The head gasket is a critical seal between the engine block and cylinder head. It prevents leaks of combustion gases, coolant, and engine oil between these components.

- Sealing Engine Block and Cylinder Head: Creates a tight seal between the engine block and cylinder head(s).

- Combustion Gas Seal: Prevents combustion gases from leaking out of the cylinders.

- Coolant and Oil Seal: Prevents coolant and oil from mixing or leaking into the cylinders.

- Material: Modern head gaskets often use thin layers of steel for durability.

Head gasket failure is a serious engine problem that can lead to overheating and engine damage.

Signs Your Head Gasket Is Blown:

- Engine Overheating: Coolant leaks due to head gasket failure cause overheating.

- White Smoke from Tailpipe: Coolant burning in cylinders produces white smoke.

- Low Coolant Level: Coolant leaks reduce coolant levels.

- Rough Idle/Engine Knock: Compression leaks from a blown gasket cause rough running.

- Contaminated Engine Oil: Coolant mixing with oil creates a milky appearance.

19. Cylinder Liner (Sleeve)

Cylinder Liner Engine Part: A cylinder liner or sleeve is shown, a replaceable inner wall of the cylinder, designed to provide a wear-resistant surface for piston movement.

The cylinder liner, also called a cylinder sleeve, is a replaceable inner wall of the cylinder within the engine block. It provides a wear-resistant surface for the piston to move against.

- Wear Surface: Provides a durable, replaceable surface for piston movement, protecting the engine block itself from wear.

- Protection: Protects the engine block from wear, heat, and contamination.

- Material: Typically made of cast iron alloyed with various elements for wear resistance and oil retention.

- Types: Three main types: dry liners, wet liners, and hot liners. Dry liners are surrounded by the block material, wet liners are in direct contact with coolant, and hot liners are used in air-cooled engines.

Cylinder liners can be replaced when worn, extending the life of the engine block.

20. Crankcase

Crankcase Engine Part: The crankcase is shown, the main housing of the engine that encloses the crankshaft, pistons, and connecting rods, providing structural support and protection.

The crankcase is the main housing of the engine. It encloses the crankshaft, pistons, and connecting rods, providing structural support and protection for these vital components.

- Main Engine Housing: Forms the central structure of the engine.

- Houses Crank Mechanism: Encloses the crankshaft, pistons, connecting rods, and related parts.

- Attachment Point: Provides mounting points for accessories, gearbox/transmission, and cylinder head.

- Cooling and Lubrication Channels: Contains channels for oil and coolant flow.

21. Engine Distributor (Older Vehicles)

Engine Distributor Part: An engine distributor is shown, a component used in older vehicles to distribute high-voltage sparks to the spark plugs in the correct firing order.

The engine distributor (primarily found in older vehicles) is an ignition component that distributes high-voltage sparks to each spark plug in the correct firing order.

- Spark Distribution: Routes high-voltage pulses from the ignition coil to the spark plugs.

- Firing Order Control: Ensures sparks are delivered to each cylinder in the correct sequence and timing.

- Components: Includes a distributor cap, rotor, and internal contacts.

Modern vehicles use distributorless ignition systems, eliminating the need for a mechanical distributor.

Symptoms of a Bad Engine Distributor:

- Car Won’t Start: Distributor failure can prevent spark delivery.

- Engine Misfiring or Backfiring: Erratic spark distribution causes misfires.

- Car Shaking: Misfires can lead to engine shaking.

- Check Engine Light: Distributor problems can trigger the light.

- High-Pitched Noise: Distributor bearing wear can cause squealing noises.

- Failed Emissions Test: Misfires increase emissions.

22. Distributor O-ring (Older Vehicles)

The distributor O-ring is a rubber seal that prevents oil leaks at the base of the distributor in older vehicles.

- Sealant: Seals the distributor housing to the engine, preventing oil leaks.

- Timing Stability: Helps maintain distributor alignment and timing accuracy.

A leaking distributor O-ring can cause oil leaks and potentially affect engine timing.

Symptoms of a Bad or Failing Distributor O-ring:

- Oil Leaking from Base of Distributor: Visible oil leak at the distributor base.

- Lack of Power: Oil contamination or timing issues can reduce power.

- Engine Running Rough: Misfires or timing problems can cause rough running.

- Engine Misfire: Oil contamination or timing inaccuracies can lead to misfires.

23. Cylinder Head Cover (Valve Cover)

Cylinder Head Cover Part: A cylinder head cover or valve cover is shown, sealing the top of the cylinder head and protecting valve train components while preventing oil leaks.

The cylinder head cover, also known as the valve cover, seals the top of the cylinder head.

- Cylinder Head Seal: Seals the top of the cylinder head, preventing oil leaks.

- Valve Train Protection: Protects valve train components (valves, springs, rocker arms, etc.) from debris and contamination.

- Material: Usually made of cast iron or aluminum alloy.

24. Rubber Grommet

Rubber Grommet Engine Part: A rubber grommet is shown, a small, flexible component used to protect wires or hoses passing through holes in metal parts, preventing abrasion and sealing against moisture.

A rubber grommet is a small, flexible ring used to protect wires, tubes, or hoses as they pass through holes in metal parts.

- Abrasion Protection: Prevents wires and hoses from being chafed or cut by sharp edges of holes.

- Sealing: Provides a seal against dust and moisture ingress.

25. Oil Filter

Oil Filter Engine Part: An oil filter is shown, designed to remove contaminants from engine oil, ensuring clean oil circulates to lubricate and protect engine parts.

The oil filter removes contaminants from engine oil, keeping the oil clean and effective for lubrication.

- Contaminant Removal: Filters out dirt, metal particles, and other contaminants from engine oil.

- Clean Oil Circulation: Ensures clean oil circulates through the engine, reducing wear.

- Construction: Consists of a metal can containing filter media (synthetic fiber) and a gasket for sealing.

Regular oil filter changes are essential for maintaining engine health.

26. Camshaft Pulley

Camshaft Pulley Engine Part: A camshaft pulley is shown, used in the timing system to drive the camshaft from the crankshaft via the timing belt or chain, ensuring synchronized valve timing.

The camshaft pulley is a toothed wheel attached to the camshaft. It’s part of the timing system and is driven by the timing belt or chain.

- Camshaft Drive: Driven by the timing belt or chain, rotating the camshaft.

- Timing System Component: Essential for maintaining correct camshaft timing.

27. Timing Belt Drive Pulley (Crankshaft Pulley)

Timing Belt Drive Pulley Engine Part: A timing belt drive pulley, or crankshaft pulley, is shown, located on the crankshaft to drive the timing belt or chain, synchronizing crankshaft and camshaft rotation.

The timing belt drive pulley, also known as the crankshaft pulley, is located on the crankshaft. It drives the timing belt or chain.

- Timing System Drive: Drives the timing belt or chain, transferring rotation from the crankshaft to the camshaft.

- Synchronization: Key component in synchronizing crankshaft and camshaft rotation.

Symptoms of a Bad Timing Belt Pulley:

- Shaky Belt Motion: Pulley bearing wear can cause belt wobble.

- Visible Wear on Pulleys: Pulley damage or wear can be visually inspected.

- Belt “Squealing” or “Whining” Noises: Worn pulley bearings can create noises.

- Knocking or Slapping Noises: Pulley damage can cause knocking sounds.

- Damaged Bearings or Pulleys: Physical damage to the pulley or bearings.

28. Water Pump

Water Pump Engine Part: A water pump is shown, responsible for circulating coolant throughout the engine and radiator to maintain optimal engine temperature and prevent overheating.

The water pump circulates coolant throughout the engine’s cooling system, preventing overheating.

- Coolant Circulation: Pumps coolant through the engine block, cylinder head, and radiator.

- Overheating Prevention: Maintains engine temperature within the optimal range.

- Drive Mechanism: Typically driven by a belt from the crankshaft pulley.

- Components: Uses impeller blades and centrifugal force to move coolant.

Water pump failure can lead to serious engine overheating.

Common Causes of Water Pump Failure:

- Contaminated Coolant: Debris in coolant can damage the pump.

- Mixed Coolant Types: Incompatible coolants can cause corrosion and pump damage.

- Cavitation: Vapor bubbles in coolant can implode and damage the pump impeller.

Symptoms of a Failing Water Pump:

- Leaking Coolant: Pump seal failure can cause coolant leaks.

- Overheating Engine: Reduced coolant circulation leads to overheating.

- Coolant Leaks into Oil: Pump seal failure can allow coolant to mix with oil.

- Engine Noise: Worn pump bearings can create whining or grinding noises.

29. Turbocharger and Supercharger (Forced Induction)

Turbocharger Engine Part: A turbocharger is shown, a forced induction device that uses exhaust gas energy to compress intake air, increasing engine power.

Supercharger Engine Part: A supercharger is shown, another forced induction device, mechanically driven by the engine to compress intake air and boost engine power.

Turbochargers and superchargers are forced induction devices used to increase engine power by compressing the intake air.

- Power Boost: Increase engine power output by forcing more air into the cylinders.

- Turbocharger: Driven by exhaust gas energy, using a turbine to power an air compressor.

- Supercharger: Mechanically driven by the engine, typically via a belt from the crankshaft.

- Efficiency vs. Immediate Power: Turbochargers are more efficient but can have turbo lag (delay in power delivery). Superchargers provide more immediate power but are less efficient.

Symptoms of a Damaged or Failing Turbocharger:

- Loss of Power: Reduced boost pressure from a failing turbo decreases power.

- Slower, Louder Acceleration: Turbo lag becomes more pronounced.

- Difficulty Maintaining High Speeds: Reduced power at higher speeds.

- Blue/Grey Smoke from Exhaust: Oil leaks in the turbo can cause smoke.

- Check Engine Light: Turbocharger issues can trigger the light.

Symptoms of a Bad Supercharger:

- Ticking Sound from Motor: Supercharger bearing wear can create ticking noises.

- Decreased Fuel Efficiency: Supercharger operation consumes engine power, potentially reducing fuel economy.

- Immediate Loss of Power: Supercharger failure results in a noticeable power drop.

30. Oil Pan Drain Bolt (Drain Plug)

Oil Pan Drain Bolt Part: An oil pan drain bolt or plug is shown, located at the bottom of the oil pan, used to drain engine oil during oil changes.

The oil pan drain bolt, also known as the drain plug, is located at the bottom of the oil pan. It’s removed to drain engine oil during oil changes.

- Oil Draining: Provides a point to drain old engine oil from the oil pan.

- Sealing: When tightened, it seals the oil pan and prevents oil leaks.

A worn or damaged drain bolt or its gasket can cause oil leaks.

Common Signs of a Worn Oil Drain Plug:

- Puddle of Engine Oil Under Car: Leaks leave oil puddles.

- Visible Damage to Drain Plug: Stripped threads or damage to the bolt head.

- Dropping Oil Level: Leaks cause a decrease in oil level.

- Engine Performance Problems: Severe oil leaks can lead to engine damage and performance issues.

31. Valvetrain

The valvetrain is the entire system that controls the movement of the engine valves. It includes valves, pushrods, lifters, and rocker arms.

- Valve Control System: Encompasses all components responsible for opening and closing engine valves.

- Components: Includes valves, valve springs, rocker arms, pushrods (in OHV engines), lifters/tappets, and camshaft(s).

32. Rocker Arms

Rocker arms are pivoting levers that transfer motion from the camshaft (or pushrods in OHV engines) to the valves, opening and closing them.

- Motion Transfer: Transmit motion from the camshaft to the valves.

- Valve Actuation: Rocker arms pivot to push valves open against valve spring pressure.

33. Pushrods/Lifters (Tappets)

Pushrods and lifters (or tappets) are used in overhead valve (OHV) engines. Lifters sit on the camshaft and transfer motion to pushrods, which then actuate rocker arms to open the valves.

- Motion Transfer (OHV Engines): In OHV engines, lifters and pushrods transfer motion from a camshaft located in the engine block to rocker arms in the cylinder head.

- Valve Actuation (OHV Engines): Pushrods actuate rocker arms to open and close valves.

34. Throttle Body

The throttle body controls the amount of air entering the engine. It regulates engine speed and power output based on driver input via the accelerator pedal.

- Airflow Control: Regulates the volume of air entering the intake manifold.

- Engine Speed Control: Controls engine RPM and power output.

- Driver Input: Responds to accelerator pedal input.

35. Fuel Injectors

Fuel injectors precisely spray fuel into the intake manifold or directly into the cylinders (in direct injection engines). They are a key part of the fuel delivery system.

- Fuel Delivery: Spray fuel into the intake air stream or directly into cylinders.

- Precise Fuel Metering: Deliver a precisely controlled amount of fuel for optimal combustion.

- Fuel Injection Systems: Different types include direct injection, port fuel injection, and throttle body injection.

36. Air Intake System

The air intake system delivers clean air to the engine for combustion. It includes the air filter, air intake ducts, and the throttle body.

- Clean Air Delivery: Supplies filtered air to the engine.

- Components: Includes air filter, air intake tubing, and throttle body.

37. Air Filter

The air filter cleans incoming air, removing dust, dirt, and other particles before it enters the engine.

- Air Filtration: Removes contaminants from air entering the engine.

- Engine Protection: Prevents dirt and debris from damaging engine components.

38. Fuel Delivery System

The fuel delivery system supplies the engine with the correct amount of fuel. It includes the fuel tank, fuel pump, fuel lines, fuel filter, fuel injectors, and fuel pressure regulator.

- Fuel Supply: Stores and delivers fuel to the engine.

- Components: Includes fuel tank, fuel pump, fuel lines, fuel filter, fuel injectors, and fuel pressure regulator.

39. Lubrication System

The lubrication system reduces friction and wear between moving engine parts by circulating engine oil. It includes the oil pan, oil pump, oil filter, and oil passages throughout the engine.

- Friction Reduction: Minimizes friction and wear between moving parts.

- Cooling: Engine oil also helps to cool engine components.

- Components: Includes oil pan, oil pump, oil filter, and oil passages.

40. Cooling System

The cooling system regulates engine temperature to prevent overheating. It uses coolant (a mixture of water and antifreeze) circulated by the water pump through the engine and radiator.

- Temperature Regulation: Maintains engine temperature within a safe operating range.

- Overheating Prevention: Dissipates heat generated by combustion.

- Components: Includes radiator, water pump, thermostat, coolant hoses, and coolant.

Common Engine Problems and Symptoms

Even with proper maintenance, engine parts can wear out or fail over time. Here are some common engine problems and their associated symptoms:

- Poor Compression:

- Symptoms: Loss of power, engine misfiring, engine won’t start.

- Cracked Engine Block:

- Symptoms: Engine overheating, white smoke from exhaust, coolant leaks (often visible on the engine block exterior).

- Damaged Pistons, Rings, and/or Cylinders:

- Symptoms: Rattling noises, blue smoke from exhaust, rough idle, failed emissions test.

- Broken or Worn Rods, Bearings, & Pins:

- Symptoms: Tapping or ticking sounds, low oil pressure, metal shavings in engine oil, rattling noises during acceleration.

Regular maintenance, including oil changes, fluid flushes, and timely replacement of belts and hoses, is crucial for preventing engine problems and ensuring longevity.

Car Engine Parts Video

Car Engine Parts Video

Car Engine Parts Explained Video: An embedded video resource providing a visual and auditory guide to understanding car engine parts and their functions.

(Note: Replace the bracketed link above with a relevant YouTube video about car engine parts for English-speaking audiences)

FAQs About Car Engines

What is an Engine?

An engine (or motor) is a machine that converts energy into mechanical motion. Most cars use internal combustion engines (ICE), which burn fuel to generate power.

How Does a Car Engine Work?

A car engine works by igniting a mixture of fuel and air inside cylinders. The expanding gases from combustion push pistons, which rotate a crankshaft, ultimately powering the wheels.

What are the Different Parts of an Engine?

Key engine parts include the engine block, cylinder head, pistons, crankshaft, camshaft, valves, spark plugs, fuel injectors, and many others. (See detailed list above).

How Many Parts are in a Car Engine?

A typical internal combustion engine has around 200 parts. Electric vehicle motors have significantly fewer, around 20.

What Engine Does My Car Have?

You can usually identify your car’s engine type by checking the Vehicle Identification Number (VIN), often found in the owner’s manual or on the driver’s side dashboard. The eighth digit of the VIN typically indicates the engine type.

Related Post: 50 Basic Parts of a Car With Name & Diagram