For many, a car is simply a tool for transportation, a means to get from one place to another. However, beneath the hood lies a complex and fascinating system – the engine. If you’ve ever wondered how your car actually moves, the answer, unless you’re driving an electric vehicle, lies within the internal combustion engine. This incredible piece of machinery orchestrates a series of precisely timed events to convert fuel into motion.

While we often refer to the engine as a single entity, it’s actually an assembly of numerous individual parts, each playing a crucial role. You might recognize some car engine parts names, but understanding their function and interaction is key to appreciating the marvel of automotive engineering.

Understanding the Heart of Your Car: The Engine

The engine is rightfully considered the heart of your car. It’s a sophisticated machine designed to transform the heat generated from burning fuel into the power that propels your wheels.

This transformation begins with a spark, igniting a mixture of fuel vapor and compressed air within a sealed cylinder. This rapid combustion creates expansion, generating the force needed to drive the car. Hence the term internal combustion engine. The robust nature of an engine is essential to withstand this demanding workload. It’s fundamentally composed of two main sections:

- The cylinder block: The lower, heavier part, serving as the main housing for the engine’s moving components.

- The cylinder head: A detachable upper section that seals the cylinder block.

Within the cylinder head are carefully designed passages controlled by valves. These passages regulate the intake of the air-fuel mixture into the cylinders and the expulsion of exhaust gases after combustion.

The cylinder block houses the crankshaft, which converts the linear motion of the pistons into the rotational motion required to turn the wheels. Often, the camshaft, responsible for operating the valves, is also located within the block, although in some designs, it may be positioned in or above the cylinder head.

How a Car Engine Converts Fuel to Motion

An internal combustion engine operates as a heat engine, converting the chemical energy in gasoline into mechanical work, or torque. This torque is then transmitted to the wheels, making your car move. Regardless of whether you drive a budget-friendly car or a high-performance sports car, the fundamental principles of engine operation remain consistent.

Engines utilize pistons that move up and down inside cylindrical chambers called cylinders. Think of it like pedaling a bicycle: your legs moving up and down rotate the pedals.

Pistons are connected to a crankshaft via connecting rods. Their reciprocating motion spins the crankshaft, much like your legs spin the bicycle’s cranks. This rotating crankshaft then powers the car’s wheels. The number of cylinders in an engine can vary, typically ranging from two to twelve, depending on the vehicle’s design and power requirements.

The Source of Engine Power: Controlled Explosions

The power in an internal combustion engine originates from a series of precisely controlled mini-explosions. These explosions are created by mixing fuel with air and igniting this mixture within the cylinders. Key components like pistons, fuel injectors, and spark plugs work in concert to achieve this.

Each ignition event is known as a combustion stroke or power stroke. The heat and expanding gases from this combustion force the piston down within the cylinder.

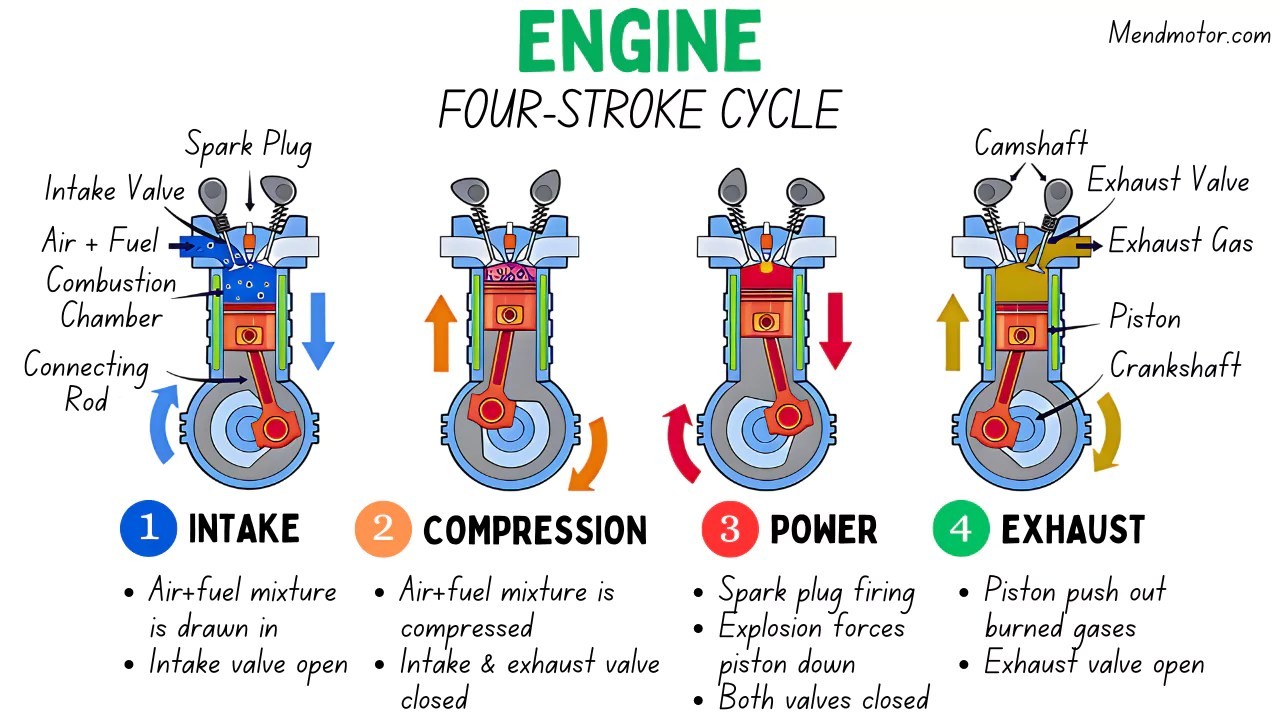

Most modern internal combustion engines are four-stroke engines, which we’ll focus on for simplicity. Besides the power stroke, there are three additional strokes: intake, compression, and exhaust.

1. The Intake Stroke

The intake stroke is the process of drawing air and fuel into the engine’s combustion chamber. The method varies based on engine type.

- Port Fuel Injection (PFI) engines: The piston moves downwards, and the intake valve opens, drawing a mixture of air and fuel into the combustion chamber.

- Gasoline Direct Injection (GDI) engines: Fuel can be injected as the piston moves down (creating a homogenous mixture) or later in the compression stroke. Many GDIs use both methods depending on driving conditions. Some manufacturers even combine port and direct injection.

2. The Compression Stroke

The intake valve closes, sealing the combustion chamber. The crankshaft completes its first revolution, driving the piston upwards and compressing the air-fuel mixture.

3. The Power Stroke

The spark plug ignites the compressed air-fuel mixture. The rapid combustion expands the gases, forcing the piston back down the cylinder.

4. The Exhaust Stroke

The exhaust valve opens, and the piston moves upwards again, pushing the exhaust gases out of the cylinder. Simultaneously, the piston applies a fresh coating of oil to the cylinder walls.

These four strokes constitute one combustion cycle. The efficient interaction of valves, pistons, crankshaft, cylinder, piston rings, and engine oil is crucial for optimal engine performance, efficiency, and longevity.

Let’s now explore the specific parts that collaborate to make this intricate process possible.

Car Engine Parts Diagram with Names: Visualizing the Engine

To better understand the location and appearance of each component, let’s examine a simple car engine parts diagram showcasing the essential elements.

Typical diagrams of this nature will highlight parts such as the engine block, combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valves, rocker arms, pushrods/lifters, injectors, spark plugs, oil pan, distributor, connecting rods, piston rings, and flywheel.

Read More: Comprehensive Guide to 50 Basic Car Parts with Names & Diagrams

Essential Car Engine Parts Names: A Detailed List

While we often think of the engine as a single unit, it’s composed of many individual parts working in perfect synchronicity.

Here’s a list of important car engine parts names:

- Cylinder headcover

- Rubber grommet

- Camshaft pulley

- Oil filter

- Water pump

- Timing belt drive pulley

- Oil pan drain bolt

- Turbocharger and supercharger

- Starter motor

A typical internal combustion engine can contain around 200 individual parts requiring maintenance and potential replacement over time. In contrast, electric vehicles significantly reduce this complexity, with approximately 20 moving parts in their powertrains. However, our focus here is on the key components of a car engine.

Exploring the Parts of a Car Engine in Detail

The intricate workings of your car’s engine rely on the harmonious interaction of various components. These include: the engine block (cylinder block), combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valve train, valves, rocker arms, pushrods/lifters, fuel injectors, and spark plugs. Let’s delve deeper into each of these parts:

1. The Engine Block

The engine block, also known as the cylinder block, is the foundational structure housing the core components where combustion occurs in a reciprocating engine.

Typically made from aluminum alloy (or cast iron in older engines), it contains the cylinders, the water-cooling system, and the crankcase.

Its robust metal construction provides strength and facilitates efficient heat transfer from combustion to the integrated cooling system. This “water jacket” is supplied by the car’s radiator, which cools the coolant before it’s recirculated into the engine block. Without effective cooling, the engine would rapidly lose efficiency and eventually seize.

The water jacket surrounds the engine’s cylinders, typically four, six, or eight in number, each housing a piston. When the cylinder head is secured to the engine block, along with the camshaft, the pistons move within the cylinders, turning the crankshaft that ultimately powers the wheels.

The oil pan is situated at the base of the engine block, acting as a reservoir for engine oil. This oil lubricates the engine’s moving parts. The oil level is monitored electronically via the dashboard or manually with a dipstick inserted into the engine block. Regular engine oil changes are crucial, performed by draining oil through the sump plug at the base of the block or using a vacuum pump via the dipstick hole. The oil filter should be replaced concurrently.

Common Symptoms of a Failing Engine Block:

- Reduced engine performance due to low compression.

- Visible engine smoke.

- Engine overheating caused by antifreeze leaks.

- Discoloration in engine oil or antifreeze.

- Oil or coolant leaks.

- Frozen coolant in the radiator.

- Excessive exhaust smoke.

- Low coolant levels.

2. The Piston

The piston is a critical moving component within a car engine. It’s a cylindrical metal part equipped with piston rings to create an airtight seal within the engine cylinder.

The piston is connected to a connecting rod via a piston pin (or gudgeon pin). The connecting rod, in turn, is linked to the crankshaft.

In four-stroke engines (both petrol and diesel), the intake, compression, combustion, and exhaust processes occur above the piston in the cylinder head. This forces the piston to move up and down (or horizontally in flat engines) inside the cylinder, causing the crankshaft to rotate.

Internal combustion engines can function with a single cylinder and piston (like motorcycles and lawnmowers) or as many as twelve, but most cars have four, six, or eight. Pistons are also used in external combustion engines (steam engines), where steam propels pistons in external cylinders to drive the wheels.

Common Symptoms of Piston Problems:

- White or gray exhaust smoke.

- Excessive oil consumption.

- Reduced power during acceleration.

- Overall power loss or poor performance.

3. The Crankshaft

The crankshaft is a fundamental car engine part. Situated in the lower section of the engine, it converts the vertical motion of the pistons into horizontal rotational motion. This rotational motion ultimately drives the wheels via the gearbox.

Modern crankshafts feature evenly spaced “throws” (four in a four-cylinder engine, as shown), connected to the pistons by connecting rods. These throws are offset from the crankshaft’s axis, generating rotational energy.

The crankshaft is supported by large bearings at each end and connects to the flywheel, and subsequently, the clutch. When the clutch is engaged, the crankshaft’s rotational energy is transmitted through the gearbox, differential, and driveshafts to the wheels, enabling the car to move.

Symptoms of a Failing Crankshaft Position Sensor:

- Difficulty starting the vehicle.

- Intermittent stalling.

- Check Engine Light illumination.

- Uneven acceleration.

- Engine misfires or vibrations.

- Rough idling and/or engine vibration.

- Reduced fuel economy.

4. The Camshaft

The camshaft is a relatively straightforward car engine part: a rod or shaft with shaped lobes called “cam lobes”. As the shaft rotates, the cam lobes act on valves or switches, with the lobe shape determining the degree of action and rotational speed controlling the rate of action.

In modern internal combustion engines, camshafts are often positioned above the cylinder banks to control the valves.

Their precise calibration dictates the amount of air-fuel mixture entering the combustion chamber and the efficiency of exhaust gas expulsion. This makes them critical for engine operation and performance, as valve timing must be perfectly synchronized with piston movement.

To ensure this timing accuracy, camshafts are connected to the crankshaft via a timing belt or chain. The shape of the cams also controls valve opening and closing speeds, known as variable valve timing.

Symptoms of a Bad Camshaft:

- Active or flashing Check Engine Light.

- Power loss.

- Popping/backfiring in the intake manifold or exhaust (severe wear).

- Loud ticking or tapping noises.

- Metal debris in engine oil.

- Cylinder misfires.

- Increased emissions due to misfires.

- Visible damage.

5. The Connecting Rod

A connecting rod transmits motion from the piston to the crankshaft, acting as a lever arm. Typically made of cast aluminum alloy, connecting rods are designed to withstand dynamic stresses from combustion and piston movement.

The small end connects to the piston with a piston pin (wrist pin), providing a pivot point. Spring clips or piston pin locks secure the piston pin.

The large end connects to the crankpin journal on the crankshaft, providing another pivot point. Connecting rods can be one-piece or two-piece. Two-piece rods have a removable rod cap, secured with cap screws, providing a bearing surface for the crankpin journal.

Symptoms of a Bad Connecting Rod:

- Low compression.

- Engine knocking sounds (rod knock).

- Low oil level or pressure.

- Visibly bent or damaged rod.

- Engine seizure.

6. Timing Belts

The timing belt is crucial for engine operation, synchronizing the movement of various components to ensure optimal efficiency and power.

It harmonizes crankshaft and camshaft rotation, ensuring pistons and valves operate correctly. Intake valves open to allow air and fuel into the combustion chamber, then close as the piston compresses the mixture. The spark plug ignites it, forcing the piston down and rotating the crankshaft. The camshaft then opens the exhaust valve to release exhaust gases.

This coordinated sequence requires precise timing. The timing belt transmits crankshaft rotation to the camshaft, maintaining synchronization. Whether your car is new or old, a functioning timing belt is essential.

Signs Your Car Needs a New Timing Belt:

Whether you have a timing chain or a rubber belt, problems are usually noticeable:

- Engine misfires.

- Ticking noise from the engine.

- Oil leaks from the front of the engine.

- Engine performance issues between 2000 – 4000 RPM.

- Excessive smoke and fumes.

- Engine won’t turn over.

7. Spark Plugs

A spark plug is an electrical device in an internal combustion engine that generates a spark to ignite the air-fuel mixture in the combustion chamber.

Part of the ignition system, the spark plug receives high-voltage electricity (from an ignition coil in modern engines, via a spark plug wire) to create a spark across the gap between its electrodes.

The timing of the spark is critical for engine performance, typically occurring just before the combustion stroke.

Symptoms of Bad Spark Plugs:

- Reduced fuel economy.

- Lack of acceleration.

- Hard starts.

- Engine misfires.

- Rough idling.

8. Cylinder Head

The cylinder head sits atop the engine block. It must withstand immense pressure and high temperatures while maintaining its shape to seal the cylinder block with the head gasket. It’s essential for controlling airflow into and out of the cylinders and for fuel delivery.

The cylinder head houses injectors and valves and contains more moving parts than any other engine component.

Inside, passages or ports guide the air-fuel mixture to the inlet valves and exhaust gases away from the engine block.

Symptoms of a Cracked Cylinder Head:

- White smoke (steam) from the exhaust pipe.

- Low coolant level.

- Engine overheating.

- Rough running and misfiring.

- Combustion gases in the cooling system.

- Illuminated warning lights.

- Coolant-oil mixture.

9. The Oil Pan

The oil pan is bolted to the bottom of the engine and serves as the reservoir for engine oil. The oil is pumped throughout the engine to lubricate, clean, and cool moving parts. A pump draws oil from the pan, passes it through a filter to remove contaminants, and then circulates it through the engine.

Typically made of steel or aluminum, the oil pan holds four to six quarts of oil, depending on engine size. The oil dipstick extends into the oil pan to measure the oil level. A drain plug at the bottom allows for oil drainage during oil changes. Oil leaks are common as engines age, and oil pans can be a source of leaks. Gaskets or seals between the pan and engine block can wear out. Drain plugs can also leak if overtightened or if washers are not replaced. Pans can also be damaged by impacts from road debris.

Symptoms of a Bad Oil Pan:

- Low oil warning light.

- Oil puddle under the car.

- Unexpected drop in oil level.

- Engine overheating.

- Burning smell from the engine.

10. Engine Valves

Gases enter and exit the combustion chamber through ports in the cylinder head, controlled by valves. There are two sets: intake valves and exhaust valves.

The inlet valve allows the air-fuel mixture to enter the cylinder, while the exhaust valve allows spent gases to exit. They open and close at precise moments for efficient engine operation at all speeds.

Valves are controlled by a camshaft that pushes each valve open directly or via linkages. Valve timing is synchronized with the piston strokes. A timing belt or chain connects the crankshaft and camshaft, keeping them synchronized.

Symptoms of Bad Valves:

- Poor cold engine performance.

- Off-throttle braking issues.

- Rough idling.

- Excessive oil consumption.

- Excessive smoke.

- Loss of engine power.

11. Combustion Chamber

A Combustion Chamber is the area within the cylinder where the air-fuel mixture is ignited. As the piston compresses the mixture and it contacts the Spark Plug, combustion occurs, releasing energy.

Consequences of Oil in the Combustion Chamber: Oil burning in the combustion chamber produces blue-grey exhaust gases. Oil can enter past valves and piston rings. Worn valve seals can allow oil to seep into cylinders overnight, causing blue exhaust fumes upon startup.

12. Intake Manifold

The intake manifold, also known as the inlet manifold, distributes air to the engine’s cylinders. In many cars, it also houses fuel injectors. In older cars without fuel injection, it delivers the fuel-air mixture from the carburetor to the cylinder heads.

The manifold allows air into the combustion chamber during the intake stroke, where it mixes with fuel from the injector. The air reaches the manifold via the air cleaner assembly and air filter, which prevents contaminants from entering the engine.

Intake manifolds are typically made of aluminum or cast iron, though some use plastic.

Symptoms Of a Bad Intake Manifold:

- Check Engine Light.

- Misfires.

- Rough idle.

- Loss of engine performance.

- External coolant leaks.

- Engine Overheating.

13. Exhaust Manifold

Bolted to the engine block, the exhaust manifold is the first part of the exhaust system. It collects exhaust gases from all cylinders and routes them to the catalytic converter. V-type engines have a manifold for each cylinder bank.

Leaks in the exhaust manifold or gasket can release exhaust gases, posing health risks and causing oxygen sensor errors, triggering the Check Engine Light. Large leaks create loud exhaust noises.

Symptoms of a Cracked or Bad Exhaust Manifold:

- Check Engine Light.

- Burning smells.

- Performance problems or sluggish acceleration.

- Poor fuel economy.

- Loud exhaust noise.

- Visible damage.

14. Piston Ring

A piston ring is a split metallic ring attached to a piston in an internal combustion engine.

Main functions of piston rings:

- Sealing the combustion chamber to minimize gas loss.

- Improving heat transfer from the piston to the cylinder wall.

- Maintaining proper oil quantity between piston and cylinder wall.

- Regulating oil consumption by scraping oil from cylinder walls back to the sump.

Most piston rings are made of cast iron or steel.

Signs to Replace Piston Rings:

- Engine misfires and rough idling.

- Discolored exhaust smoke.

- Poor acceleration.

- Increased oil consumption.

- Engine overheating.

15. Gudgeon Pin

A gudgeon pin, also known as a wrist pin, connects the connecting rod and the piston, providing a pivot point. It allows the connecting rod to pivot as the piston moves.

Gudgeon pins are also used in linkages with connecting rods and wheels or cranks. In early engines, the gudgeon pin was in a sliding crosshead connected to the piston via a rod. “Gudgeon pin” is common in the UK, while “wrist pin” is preferred in the US and Canada.

16. Cam

A cam is a rotating or sliding part in a mechanical linkage, converting rotary motion to linear motion. Often part of a rotating wheel or shaft, it strikes a lever at points on its path.

In engines, the camshaft is a shaft with cams that convert rotary motion to valve linear motion, controlling valve timing. The shape of the cams significantly impacts engine characteristics and performance. A worn cam affects the timing of the air-fuel mixture in and out of combustion chambers.

17. Flywheel

In a manual transmission, the flywheel is a thick metal disc, typically made of cast iron, steel, or sometimes aluminum. It’s rigid to prevent flexing. Gear teeth on its edge engage with the starter motor.

Bolted to the crankshaft within the bell housing, the flywheel’s surface is machined flat for clutch disc engagement.

Flywheel Functions:

- Provides rotational inertia to keep the engine running smoothly.

- Balances the engine to reduce vibrations.

- Enables electric starting via the starter motor engaging the starter ring.

- Connects the engine to the transmission via the clutch to transfer power.

Symptoms of a Bad Flywheel:

- Slipping gears.

- Inability to change gears.

- Burning odor.

- Clutch vibrations (clutch chatter).

- Starting issues or inconsistent starts.

- Engine stalling.

- Engine vibrations with clutch engaged.

18. Head Gasket

The head gasket seals between the engine block and cylinder head(s). It’s vital for maintaining pressure within the combustion chamber and preventing coolant and oil from mixing.

Bad Head Gasket Symptoms:

- White smoke from the tailpipe.

- Bubbling in the radiator and coolant reservoir.

- Unexplained coolant loss without external leaks.

- Milky white oil.

- Engine overheating.

19. Cylinder Liner

A Cylinder Liner is fitted into the engine block to form the cylinder, a critical part of the engine’s interior.

Cylinder liners form the inner cylinder wall, directly contacting piston rings. They have excellent anti-galling properties for sliding surfaces, retaining oil and glaze for lubrication, reducing wear and oil consumption.

Liners are manufactured to tight tolerances to prevent compressed gas and combustion gas leaks, ensuring efficient and safe engine operation under high temperature and pressure.

20. Crankcase

The crankcase is the central part of a car engine, housing the crank mechanism, including pistons, cylinders, and connecting rods. Accessories, the transmission/gearbox, and the engine control system with the cylinder head are attached to it.

The crankcase is the most complex cast part in a combustion engine due to the oil and cooling channels required for lubrication and cooling.

21. Engine Distributor

An engine distributor is part of the ignition system, distributing high-voltage electricity to each spark plug at the correct time to ignite the fuel and power the engine.

It sends high-voltage electricity from the ignition coil to the spark plugs in the correct sequence. Components include the rotor arm, ignition points or electronic ignition, and distributor cap. Modern cars use electronic ignition systems with computer-controlled sensors.

Distributor failure can cause performance issues, loud noises, and increased emissions.

Signs of a Faulty Distributor: (Symptoms were not listed in the original text, needs to be researched and added if possible for completeness, but following instructions to stick to original content.)

22. Distributor O Ring

The distributor O-ring seals the distributor housing to the engine, preventing oil leaks at the base of the distributor. Failure can cause oil leaks, leading to other problems.

A bad O-ring leads to oil and grime buildup on the intake and distributor exterior. Regular servicing and tune-ups every 30,000 miles can help prevent this.

Symptoms of a Bad Distributor O-Ring:

- Oil leaking from the base of the distributor.

- Lack of power.

- Rough engine running.

- Engine misfires.

23. Cylinder Headcover

Cylinder head covers seal off the cylinder head space from the engine exterior. They contain blow-by gases from combustion and oil drops from the engine’s lubrication system within the cylinder head.

24. Rubber Grommet

Rubber grommets in cars prevent metal parts from chafing, reduce vibration, and seal engine parts. Their abrasion and temperature resistance make them ideal for automotive use, improving engine part lifespan and performance.

25. Oil Filter

A car’s oil filter filters waste and keeps oil in the right place, ensuring clean motor oil for optimal engine performance. It captures debris, dirt, and metal fragments from motor oil, keeping the engine running smoothly.

Without an oil filter, contaminants can damage the engine. Filtering keeps oil cleaner longer, improving engine performance. Over time, accumulated contaminants clog the filter, increasing impurity risk and lowering oil pressure.

Not replacing the filter can lead to unfiltered oil circulating, causing engine damage. Oil should be changed every 3,000 miles, and the oil filter is recommended to be replaced with each oil change by many manufacturers.

26. Camshaft Pulley

A camshaft pulley is part of the engine’s timing system, controlling the rotation rate of the camshaft. It works with the timing chain to rotate the camshaft synchronously with the crankshaft, controlling valves for air intake and exhaust.

Most crankshaft pulleys have a rubber ring to dampen engine vibrations, preventing them from transferring to the accessory drive belt.

A common symptom of a faulty camshaft pulley is unusual noise, such as rattling, ticking, grinding, or squealing.

27. Engine Starter Motor

The starter is a small, battery-powered motor that starts the engine. A starter relay transmits power from the battery to the starter motor.

Turning the key activates the ignition system and a solenoid switch, sending power from the battery to the starter. The solenoid engages an electromagnet, connecting the battery cable to windings in the starter motor and pushing a plunger to engage gears with the flywheel.

Signs of a Bad Starter:

- Whirring, grinding, or clicking sounds when starting.

- Loud single click with no engine crank.

- Normal instrument cluster, headlights, radio, but nothing happens when turning the key.

28. Water Pump

A water pump is part of the cooling system, circulating coolant through the engine to regulate temperature. Typically belt-driven and located near the front of the engine block.

It’s critical for maintaining engine temperature, preventing damage or seizure. The engine turns the water pump’s belt, rotating the pump’s axle and vanes. Rotation creates suction, drawing coolant from the radiator. Centrifugal force pushes coolant against pump walls and into the engine block, circulating through cylinder heads and back to the radiator.

Modern water pumps can last over 100,000 miles, older models 60,000-100,000 miles. Replacement costs vary.

Symptoms of a Failing Water Pump:

- Coolant leak.

- Engine overheating.

- High-pitched whining noises.

- Water pump rust and corrosion.

- Steam from under the hood.

- Leaks from the water pump.

29. Turbocharger and Supercharger

Turbochargers and superchargers are forced induction systems that increase engine power by compressing air intake.

Turbochargers use exhaust gas to spin turbine and compressor fans. Superchargers are engine-driven via a belt and pulley. Turbochargers are generally preferred for better fuel economy and reduced emissions.

30. Oil Pan Drain Bolt

The oil drain plug is a screw plug at the bottom of the oil pan used to drain old oil during oil changes. It seals the drain opening, often with a sealing ring.

Located at the oil pan’s lowest point for complete drainage, it should be checked for leaks if oil levels drop. Leaks can occur due to a missing or deformed crush washer, a damaged gasket, or overtightening. Damaged threads may also cause leaks.

Read more: Comprehensive Guide to 50 Basic Car Parts With Name & Diagram

FAQs

What Is an Engine?

An engine (or motor) converts energy into mechanical energy. Modern vehicles primarily use internal combustion engines (ICE), which burn fuel to generate mechanical motion.

How Does a Car Engine Work?

The engine uses a fixed cylinder and a moving piston. Combustion gases push the piston, rotating the crankshaft. This motion drives the vehicle’s wheels through the powertrain.

What are the different parts of an engine?

Engine parts include: engine block (cylinder block), combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valve train, valves, rocker arms, pushrods/lifters, fuel injectors, and spark plugs.

How many parts are in a car engine?

A typical internal combustion engine has about 200 parts, while electric vehicles have around 20.

What Engine Does My Car Have?

Identify your engine type via the VIN in the owner’s manual or under the hood. The eighth digit of the VIN indicates engine information.