For over 35 years, I’ve been immersed in the world of auto repair, and one thing that still surprises me is how many car owners aren’t fully aware of what happens after they pour oil into their engine. Most people know engine oil goes in at the top and drains from the bottom, but the intricate journey oil takes throughout your engine and the vital Car Oil Parts involved often remain a mystery. This understanding is crucial for proper car maintenance and ensuring the longevity of your vehicle’s engine.

One of the most frequent questions I encounter as a mechanic is:

“How often should I change my car’s oil, and what type should I use?”

To give you the best advice, I usually respond with a few questions of my own, much like a Socratic dialogue: What kind of vehicle do you drive? What are your typical driving conditions? Where do you live, considering climate variations? And how old is your car? The answers to these questions are vital in determining the optimal engine oil for your specific needs and the ideal oil change intervals to guarantee your engine is well-protected and lubricated by the car oil parts system.

Exploring the Journey of Engine Oil Through Car Oil Parts

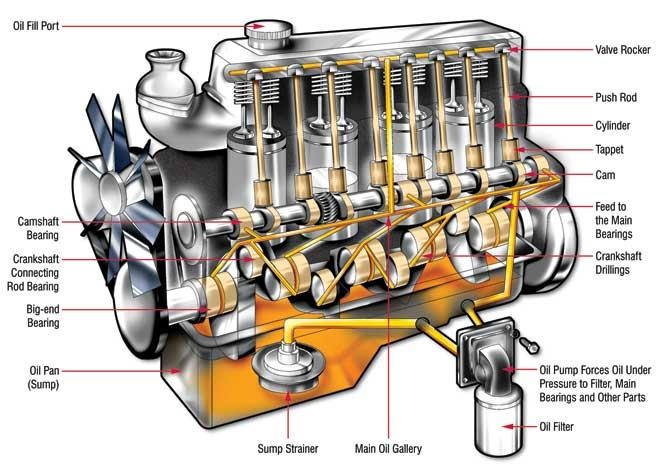

Let’s delve into the fascinating path your engine oil takes, the sequence of its journey, and the critical functions it performs within your engine. When you pour oil into your engine, it embarks on a complex route, eventually collecting in the oil pan, or sump, at the bottom—where the drain plug is located. While there are several return paths to this sump, there’s a single, pressurized path that’s crucial for the oil to do its job of lubrication through various car oil parts.

Figure 1 illustrates a key component: the oil pickup tube. This tube, submerged in oil within the sump, features a loose-weave metal screen at its end. This screen is a simple but effective car oil part, preventing larger debris, anything bigger than approximately 1/32nd of an inch, from being drawn into the oil pump. This is the first line of defense in keeping the car oil parts system clean and functional.

Many people are unaware that the oil pump, a critical car oil part, is often a relatively simple assembly of specialized gears. These gears draw oil in at low pressure and then compress it to a higher pressure. The pressurized oil then flows through a chamber equipped with a spring-loaded valve. This valve is another important car oil part, regulating the oil pressure to a specified range, typically between 1 and 60 psi. Excess pressure is vented back to the sump to prevent damage to engine bearings – highlighting the importance of pressure control within the car oil parts system.

From the oil pump, the oil is directed to the oil filter. This car oil part is essential for cleaning the oil. The oil enters the filter from the outside and is forced through the filter media to the center before exiting into the engine’s oil galleries. The oil filter also incorporates a bypass valve, a safety car oil part that ensures oil flow is maintained even if the filter becomes clogged, preventing dangerously low oil pressure. The primary function of motor oil is to lubricate the engine’s moving parts, and adequate pressure within the car oil parts system is paramount for this task.

The pressurized oil is then forced into the narrow spaces between bearings and crankshaft journals. Bearings, fundamental car oil parts, are essentially metal sleeves that encircle the engine’s rotating components. The engine block houses main bearings on the crankshaft, while connecting rod bearings are positioned on the crank throws.

This incredibly thin gap, often just one-thousandth of an inch in modern engines, maintains a crucial film of oil between the bearings and the rotating crankshaft surfaces. At the correct operating temperature and pressure, this oil film, delivered by the car oil parts, protects and extends the life of these precisely machined components. Metal-to-metal contact between moving parts is detrimental, and the oil, circulated by the car oil parts system, prevents this wear.

It’s worth noting that some oil inevitably escapes from the sides of the bearings, dripping back into the sump. However, excessive bearing clearance, say 0.004 inches or more, can lead to a drop in oil pressure, especially in the upper engine areas. A flickering oil pressure light or a slight tapping noise from the rocker arm area can indicate insufficient oil pressure reaching the upper engine – a sign of potential issues within the car oil parts or excessive wear.

While considering improvements, one might envision an automotive engine utilizing roller or needle bearings instead of the more common sleeve bearings. Although significantly more expensive to manufacture, such an engine, with enhanced car oil parts, could potentially offer unparalleled longevity. Larger engines often employ needle/roller bearings, typically operating at lower RPMs than gasoline car engines, where RPM is not the primary limitation.

In model airplane engines, some of which reach speeds exceeding 25,000 RPM, roller bearings are frequently used to minimize friction and enable higher RPMs. An automotive engine equipped with roller/needle bearings, representing an upgrade to car oil parts, could offer increased power and lifespan, but the production costs would be considerably higher.

While a significant portion of the oil lubricates the crankshaft area, the remaining oil is directed to lubricate the camshaft and rocker arms. In engines with pushrods, oil is pressurized into the valve lifters, another set of car oil parts. These lifters also pump oil through hollow pushrods to lubricate the rocker arm area. For overhead cam engines, oil is delivered to the camshaft and then flows over the contact points between the cam and valve stems.

After lubricating the camshaft and related valve train components, the oil, having performed its function through various car oil parts, flows by gravity back down through channels in the head and engine block, returning to the sump to begin its cycle anew.

Many connecting rod designs incorporate a small orifice that sprays oil onto the cylinder walls. This lubricates the piston ring contact area within that cylinder. Special oil control rings, part of the piston ring set, then scrape off excess oil and return it to the sump.

Regarding oil consumption, it’s often necessary to add a quart of oil between regular 3,000-mile intervals. Newer cars may not consume any oil during the initial oil change intervals, but oil consumption typically increases gradually as the engine ages and car oil parts experience wear. Ideally, oil consumption of about one quart every 5,000 miles is acceptable. Some engines, even when consuming a little oil, can signal the need for an oil change by becoming a quart low around the 4,000-mile mark.

Slight oil consumption can even be beneficial. In my experience, engines that allow a small amount of oil to bypass the rings often exhibit minimized wear on the upper cylinder and rings. Historically, “top oil” additives were used in gasoline for this very purpose.

External oil leaks, however, are undesirable. They are messy, pose a fire risk, and are generally unsightly. Used car dealerships often meticulously clean engines to improve their visual appeal before sale. A clean engine creates a better initial impression. If a salesman starts the car before opening the hood, they are relying on the sound of a smooth engine to distract from a potentially dirty engine bay.

If an engine hasn’t been cleaned, it may indicate an oil leak the dealer is trying to conceal. When test driving a used car, observe where it’s parked. Oil stains on the lot can be a strong negotiating point. Many oil leaks originating from car oil parts seals or gaskets can be repaired relatively inexpensively.

Understanding Oil Consumption Patterns in Car Oil Parts Systems

We recently received a reader question concerning a change in oil consumption in their vehicle. After 30,000 miles of no noticeable oil consumption between changes, their car suddenly began consuming oil at a rate of one quart per 1,000 miles. While this rate is indeed excessive, suggesting a leak or oil burning issue, the reader posed several valid questions:

- What is considered normal oil consumption? And why might a car not consume oil for the first 30,000 miles?

- Why does oil consumption seem to occur primarily during highway driving rather than stop-and-go conditions?

- What could cause such an abrupt change in oil consumption after a period of consistent performance?

Oil consumption generally increases with vehicle age and wear on car oil parts. “Normal” consumption is subjective, but I consider one quart per 5,000 miles to be reasonable. Many new cars exhibit minimal or no oil consumption initially, but this is variable.

The fact that increased consumption occurs mainly during highway driving suggests an internal oil leak, possibly around valve stem seals or a problem within the PCV (Positive Crankcase Ventilation) system, both integral car oil parts systems.

The sudden onset of this consumption pattern strongly indicates a recent fault – either a newly developed leak or a change leading to abnormal oil burning within the car oil parts system.

I have a car with over 175,000 miles that consumes oil at my preferred rate: one quart every 4,000 miles. My newer car, with 70,000 miles, also consumes about one quart every 4,000 miles, a pattern it has maintained since new.

Detecting oil leaks in modern cars can be challenging. Engine compartments are often tightly packed, limiting visibility. The numerous accessories mounted to the engine block further obscure potential leak sources among the car oil parts. However, in an upcoming article in Machinery Lubrication, we will explore advanced leak detection techniques, including phosphorescence, polymer acrylics, ultraviolet dyes, smoke testing, and even the use of mirrors.

About the Author