Building your own bookshelf speakers can be a rewarding project, especially when you repurpose Car Speaker Parts for a unique audio experience. This guide, inspired by a project from an experienced builder, will walk you through the process of creating your own bookshelf speakers using car speaker components. This is a fantastic way to explore audio design and potentially save money while achieving great sound.

Understanding the Project: Design Goals and Component Selection

The primary goal of this project is to maximize bass extension in a compact single speaker while maintaining reasonable high-frequency response. This is a common aim for many audio enthusiasts, whether for home or car audio setups. The original builder, Alan, leveraged his experience with transmission line subwoofers to tackle this full-range speaker project.

Initially, Alan used Kicker R4c midrange car speakers from a previous car audio project. These were readily available, highlighting the resourceful nature of DIY audio projects. However, after experiencing issues with bass handling, these were replaced with Dayton Audio RS100T-8 4″ Reference Woofers. The Dayton RS100T is a significant upgrade due to its lower resonant frequency (Fs) and higher linear excursion (Xmax), crucial for achieving better bass performance. The truncated frame version was specifically chosen to ensure ventilation isn’t blocked within the enclosure. This driver selection is a key aspect when considering car speaker parts for home audio, as car and home audio environments have different acoustic needs.

Enclosure Design: Transmission Line Principles

The enclosure design is based on a transmission line (TL) principle. Transmission lines are known for their ability to extend the low-frequency response of a speaker by using a long, folded pathway to manage the rear sound waves from the driver. In this design, behind the speaker, the pipe starts at a 3-inch depth and tapers down to a 1-inch exit. This tapering and the long path contribute to the speaker’s bass performance.

The enclosure itself is constructed with a 4-inch internal width. The total length of the transmission line is 74 inches, which is tuned to a quarter wavelength resonance at 46 Hz. This tuning frequency is designed to reinforce the bass frequencies produced by the Dayton Audio woofer, maximizing the low-end extension of these bookshelf speakers.

Enclosure Assembly: Step-by-Step Construction

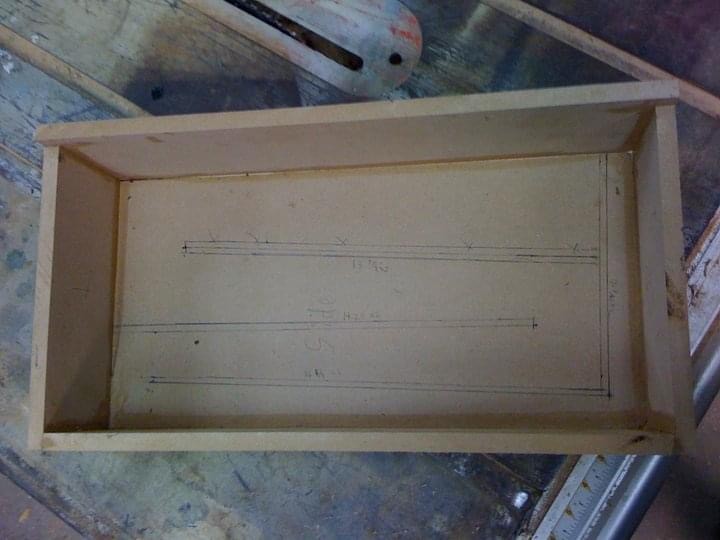

Building the enclosure requires careful assembly. The exterior of the box uses 1/2” MDF (Medium Density Fiberboard), a common material for speaker enclosures due to its density and acoustic properties. The MDF panels are glued and clamped using Titebond II wood glue, ensuring a strong and airtight seal.

The internal baffles, which form the transmission line pathway, are made from 1/4” HDF (High-Density Fiberboard). HDF is chosen for its rigidity and thinner profile, allowing for more complex internal shapes within the limited enclosure space. These baffles are also glued using Titebond, and temporarily secured with cleats and staples until the adhesive sets completely. To create clean 45-degree corners within the transmission line, small pieces of rubber foam were used during the gluing process to hold the angles in place. This meticulous assembly process is crucial for the acoustic performance of the speaker.

Crossover and Tuning: Full Range Simplicity

This speaker design employs a full-range approach, meaning no crossover is used. The Dayton RS100T woofer is designed to handle a wide frequency range, simplifying the design and build process. While some advanced designs utilize crossovers to optimize frequency distribution to different drivers (like tweeters and woofers), a full-range design can be excellent for smaller speakers and for projects aiming for simplicity.

To fine-tune the speaker’s sound, particularly to address a weird echo resonance detected during initial testing, the builder lightly stuffed the first section of the transmission line behind the speaker with polyfill. Polyfill is a common damping material used in speaker enclosures to absorb unwanted internal reflections and resonances, leading to cleaner and more accurate sound reproduction.

Performance and Conclusion: Impressive Bass from Car Speaker Parts

The conclusion of this project highlights the impressive bass extension achieved from a relatively small 4-inch speaker. While these speakers won’t produce room-shaking bass, they offer excellent low-end response for relaxed listening. The high-frequency performance is also noted as having a nice, wide image and being non-fatiguing, making them suitable for extended listening sessions.

Notably, the builder praised the vocal reproduction with the Dayton RS100T drivers, finding it outstanding. This positive experience even led to the consideration of using these speakers as dash speakers in a future car audio build. This full-circle consideration, using car speaker parts for home audio and then considering them back for car audio, demonstrates the versatility of quality components and DIY audio projects.

Tips and Tricks for DIY Speaker Builders

Building a multi-fold transmission line enclosure can be challenging. The designer recommends using graph paper to plan out the design. Visualizing the folded path and dimensions on graph paper can greatly simplify the design process and help ensure accurate cuts and assembly. Patience and iterative design are key to successfully constructing complex enclosures like transmission lines.

Parts List for the Project

| Part # | Description | Qty |

|---|---|---|

| 295-338 | Dayton Audio RS100T-8 4″ Reference Woofer Truncated Frame | 1 |

This project showcases how resourceful DIY enthusiasts can utilize car speaker parts, like drivers originally intended for vehicle audio, to create impressive home audio speakers. By understanding enclosure design principles and carefully selecting components, you can achieve excellent sound quality through DIY speaker building.