Shopping for new tires can often feel overwhelming, especially when faced with technical terms and unfamiliar jargon. Understanding the various components that make up a car tire is crucial not only for selecting the right tires for your vehicle but also for ensuring your safety on the road. At carparteu.com, we believe in empowering drivers with knowledge. This guide breaks down the anatomy of a car tire, explaining each part and its function in clear, easy-to-understand terms. Whether you drive a passenger car, SUV, CUV, or light truck, all tires share fundamental components that contribute to performance and safety.

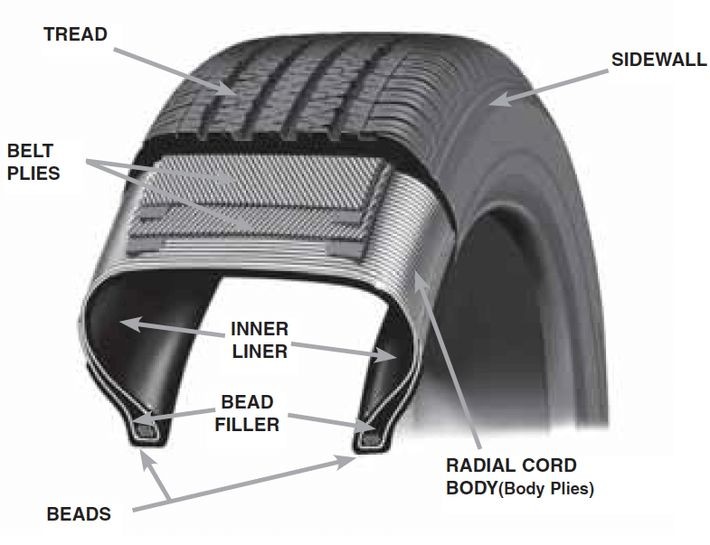

Diagram of car tire parts

Diagram of car tire parts

Beads

Starting from the innermost part of the tire, the beads are essential for securing the tire to the wheel rim. These robust components are constructed from high-tensile steel wires, often plated with copper, brass, or bronze for enhanced durability and corrosion resistance. Wound into a tight rubber band, the tire beads create a firm grip, preventing the tire from slipping or losing its position on the wheel rim as it rotates. This secure connection is vital for maintaining tire pressure and ensuring safe handling.

Bead Filler

Positioned just above the beads, the bead filler is a specialized rubber compound that plays a critical role in tire stability. Located inside the tire’s bead area, this component provides reinforcement to the lower sidewall region. The characteristics of the bead filler, such as its density and stiffness, are key factors in determining a tire’s overall performance capabilities. A well-designed bead filler contributes to improved handling response and stability, particularly during cornering and high-speed maneuvers.

Radial Cord Body

The radial cord body is the structural foundation of the tire, providing essential strength and transmitting forces between the tread and the wheel. This layer is composed of rubber-coated fabric cords, known as body plies. Common materials for body plies include polyester, rayon, and nylon, with polyester being the most prevalent choice due to its balance of strength, flexibility, and cost-effectiveness. The cord body’s construction and materials directly influence the tire’s load-bearing capacity and its ability to handle cornering forces effectively.

Inner Liner

Acting as the tire’s airtight seal, the inner liner is a crucial component for maintaining proper inflation pressure. This layer is made of a specialized rubber compound that is bonded to the inside of the cord body. Unlike older tire designs, modern car tires are tubeless, and the inner liner performs the function of an inner tube by preventing air from escaping through the tire structure. The integrity of the inner liner, in conjunction with the beads and bead filler, is paramount for reliable tire performance and safety.

Belt Plies

Situated beneath the tread area, belt plies are robust layers that significantly enhance the tire’s strength and stability. Typically consisting of two or more layers, these plies are made from strong cord materials, with steel being the most common. The primary functions of belt plies include providing resistance to punctures and impacts, improving tread wear, and enhancing traction. By adding rigidity to the tread area, belt plies contribute to improved mileage, handling precision, and overall tire durability.

Sidewall

The sidewall is the side portion of the tire, extending from the bead to the edge of the tread. This area serves as a protective barrier for the underlying cord body and also provides a space for crucial tire information. Manufacturers print essential details on the sidewall, including tire size, load index, and speed rating, allowing drivers to understand the tire’s specifications and capabilities. Sidewall rubber compounds are engineered to withstand environmental factors like ozone and resist damage from cuts and abrasions.

Tread

The tread is the outermost layer of the tire, designed to make contact with the road surface and provide grip, traction, and handling. The tread’s rubber compound and pattern are carefully engineered to balance various performance characteristics, including wear resistance, wet and dry traction, handling responsiveness, and fuel efficiency. Tread designs vary widely depending on the intended use of the tire.

For example, all-season tires like the Destination LE2 feature circumferential tread grooves. This design efficiently channels water away from the tire’s contact patch, enhancing wet road grip and reducing hydroplaning risk.

Conversely, high-performance all-season tires such as the Firehawk GT Pursuit, designed for law enforcement and emergency vehicles, often incorporate asymmetrical tread patterns. These patterns combine larger outer tread blocks for enhanced dry handling with inner shoulder areas featuring smaller, more numerous elements to improve wet and snow traction.

Ensuring a firm grip on the road begins with understanding your tires. For expert guidance on selecting the ideal tires for your vehicle and gaining deeper insights into Car Tire Parts, visit your local Firestone Complete Auto Care to consult with their experienced technicians. They are dedicated to assisting you in finding the best tires for your car, prioritizing both performance and safety.