Wheels are arguably one of the most fundamental inventions in human history, and they are absolutely essential to every car on the road today. From high-performance sports cars to everyday family vehicles, the wheel is the unsung hero that allows us to move. Without a properly functioning set of wheels and tires, your car becomes nothing more than a stationary object. While car wheels may appear simple at first glance, they are actually composed of several key components working together to ensure smooth, safe, and efficient driving.

To deepen your understanding of your vehicle and how it operates, it’s crucial to learn about the basic parts that make up a car wheel. This knowledge empowers you to better maintain your vehicle, troubleshoot potential issues, and ensure it remains in optimal condition for years to come. Let’s explore the anatomy of a car wheel with a helpful diagram and detailed explanations of each part.

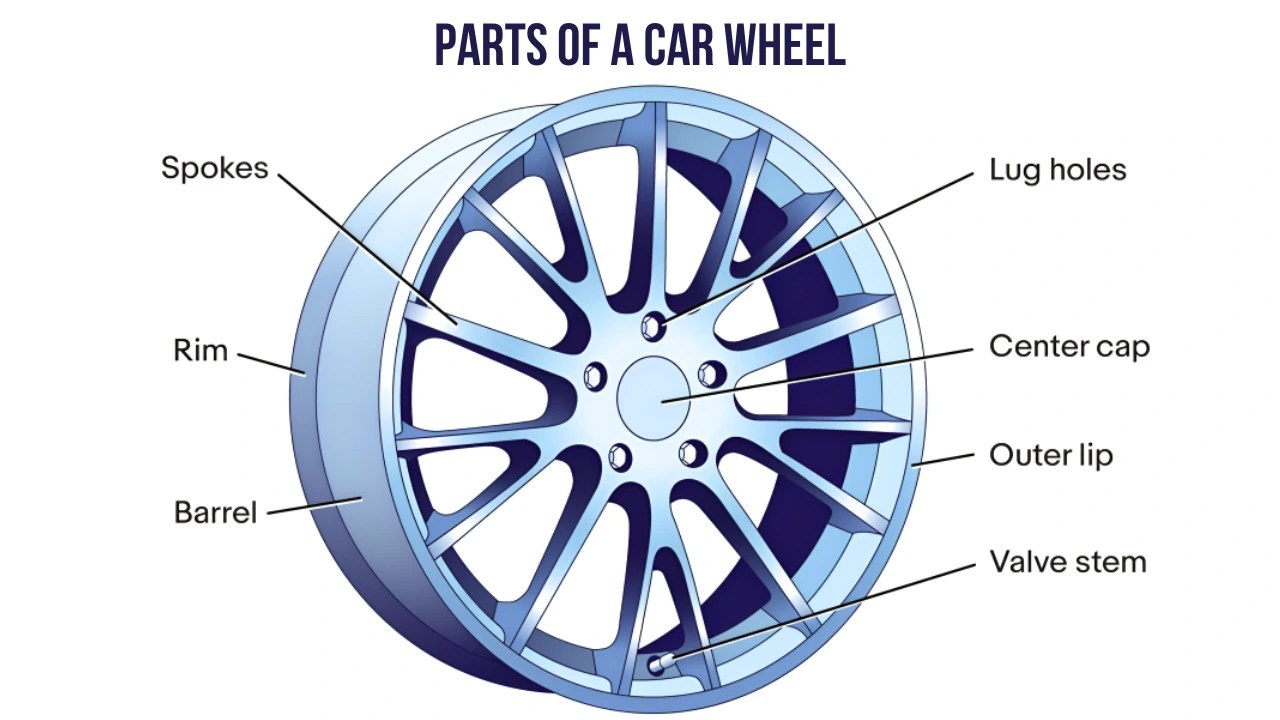

Diagram of Car Wheel Parts

Diagram of Car Wheel Parts

Key Components of a Car Wheel

A car wheel is more than just a single piece; it’s an assembly of different parts, each with a specific role. We can break down the car wheel into several essential components, which include the tire, the rim, and the hub as primary parts, and then delve into more detailed elements.

#1. The Tire

The tire is the most outwardly visible part of the wheel and the component that directly interacts with the road surface. It’s more than just a rubber ring; modern tires are sophisticated pieces of engineering designed for grip, durability, and ride comfort. Filled with air, tires provide a cushion between the road and the vehicle, absorbing shocks and vibrations for a smoother ride.

Modern tire technology has evolved significantly over the past century. Early tires were solid rubber, offering minimal cushioning. Today’s pneumatic tires provide superior handling and safety, especially in diverse weather conditions like rain, ice, and snow. Choosing the right type of tire for your vehicle and driving conditions is paramount for safety and performance. Different tire types exist, including all-season, summer, winter, and performance tires, each designed with specific tread patterns and rubber compounds to optimize performance in their intended environments.

#2. The Rim

The rim serves as the structural foundation of the wheel assembly. Think of it as the skeleton to the tire’s skin. The tire is mounted and sealed onto the rim, which provides the necessary shape and support to hold the air within the tire. Rims are typically manufactured from steel or aluminum alloys, balancing strength with weight. Aluminum rims are often preferred for performance vehicles due to their lighter weight, which can improve handling and fuel efficiency.

Rims come in a vast array of styles, from simple steel wheels often seen with hubcaps to elaborate and visually striking alloy designs. The style and finish of the rim contribute significantly to the overall aesthetic of the vehicle. Trucks and heavy-duty vehicles often utilize more robust rims designed to withstand heavier loads and demanding conditions, prioritizing function and durability over purely cosmetic appeal. The diameter and width of the rim are critical measurements that dictate the compatible tire sizes and types.

#3. The Hub

The hub is the central part of the wheel, acting as the crucial interface between the wheel and the vehicle itself. It’s the point of attachment to the car’s axle and houses vital components like brake rotors, calipers, and wheel bearings. The hub facilitates both the rotation of the wheel for movement and the stopping power of the brakes.

Typically, wheel hubs feature wheel studs – threaded bolts that protrude outwards. The wheel is positioned over these studs and secured with lug nuts. The design and integrity of the hub are critical for wheel stability and overall vehicle safety. Wheel bearings, located within the hub, allow the wheel to rotate smoothly with minimal friction, contributing to efficient and effortless motion.

#4. Spokes

Spokes are the structural elements that connect the central hub to the outer rim. They are essential for providing the wheel’s structural integrity and distributing load effectively across the wheel assembly. Along with the hub, spokes form the visible face of the wheel, contributing significantly to its design and appearance.

Wheel spoke design is not just about aesthetics; it’s also an engineering consideration. The number, shape, and arrangement of spokes can influence the wheel’s strength, weight, and even vibration characteristics. Five-spoke wheels are a common design due to their balanced distribution of stress and vibration dampening qualities. While spoke design contributes to the visual appeal of custom wheels, material and construction methods often play a more significant role in overall wheel performance and weight.

#5. Outer Lip

The outer lip is the outermost edge of the wheel, positioned in front of the spokes. The depth of the outer lip, often referred to as the “dish,” is primarily an aesthetic design element. Wheels with a significant distance between the spokes and the outer edge are considered deep-dish wheels, a popular style choice for visual enhancement.

While deep-dish designs can be visually appealing, it’s important to note that an extremely deep dish can potentially make the wheel face more susceptible to damage from impacts and curb rash. The outer lip design balances aesthetics with practical considerations of wheel durability.

#6. Barrel

The barrel is the main cylindrical body of the wheel, forming the structure to which the tire is mounted. It encompasses several key features that are crucial for tire installation and secure fitment. Within the barrel, the narrowest diameter is known as the drop center.

The position of the drop center – whether closer to the front or back face of the wheel – determines if it’s a front mount or reverse mount wheel. The barrel edges are flared outwards, creating flanges that are essential for retaining the tire and preventing it from slipping off the rim during use. The outer flanges also contribute to the cosmetic appearance of the wheel.

#7. Beads

Located just inside the flanges are the bead seats, flat surfaces designed for the tire beads to rest upon. The tire bead is the reinforced edge of the tire that creates an airtight seal against the wheel rim. Proper seating of the tire beads on these surfaces is critical for maintaining tire pressure and ensuring a secure connection between the tire and wheel.

#8. Flanges

Flanges are the flared edges found on both the inboard and outboard sides of the wheel barrel. Their primary function is to prevent the tire from slipping or coming off the wheel rim, particularly during cornering or under stress. These flared edges provide a critical safety feature, ensuring the tire remains securely mounted to the wheel under various driving conditions.

#9. Mounting Humps (Bead Humps)

Mounting humps, also known as bead humps, are small ridges strategically placed along the inside of each bead seat. These subtle ridges play a vital role in preventing tire bead slippage and maintaining the tire bead’s position against the wheel rim. They act as a secondary safety measure, further ensuring the tire stays firmly seated, especially in situations involving sudden maneuvers or impacts.

#10. Drop Center

The drop center is the narrowest section within the barrel of the wheel. Its specific purpose is to facilitate tire mounting during installation. This reduced diameter allows the tire to be maneuvered onto the wheel without excessively stretching the tire beads. The drop center is essential for practical tire fitting and removal.

#11. Center Cap

The center cap is a removable cover designed to conceal the center bore on the exterior face of the wheel. In many modern vehicles, the center cap also serves to protect the lug nuts and the wheel hub from dirt, debris, and potential damage. Center caps can be purely functional or decorative, often featuring manufacturer logos or stylized designs.

#12. Valve Stem

The valve stem is a crucial component integrated into the wheel rim, providing a port for inflating the tire with air. This small, typically metal, valve is designed to maintain air pressure within the tire and allows for pressure adjustments as needed. Many modern vehicles also incorporate TPMS (Tire Pressure Monitoring System) sensors into the valve stem assembly to monitor tire pressure and alert the driver to any significant pressure loss.

Additional Car Wheel Parts

Beyond these main components, several other parts contribute to the overall wheel system:

- Wheel Studs: Threaded fasteners permanently attached to the wheel hub, providing the mounting points for the wheel.

- Lug Nuts: Fasteners that screw onto the wheel studs to secure the wheel to the hub.

- Wheel Bearings: Allow smooth rotation of the wheel around the axle, reducing friction and wear.

- Wheel Spacers: Used to adjust wheel offset, pushing the wheel further out from the vehicle hub for aesthetic or clearance purposes.

- Wheel Seal: Prevents contaminants from entering the wheel bearing assembly and grease from escaping.

- Wheel Bolts: An alternative to wheel studs, bolts pass through the wheel and thread directly into the hub.

- Wheel Locks: Specialized lug nuts or bolts that require a unique key for removal, providing theft deterrence.

- TPMS Sensor (Tire Pressure Monitoring System Sensor): Monitors tire pressure and transmits data to the vehicle’s computer system.

- Rim Flange: The outer edge of the rim where the tire bead seats.

- Wheel Balancing Weights: Small weights attached to the rim to balance the wheel-tire assembly, minimizing vibrations at higher speeds.

- Wheel Valve Cap: A protective cap that screws onto the valve stem to keep out dirt and debris and prevent air leaks.

- Dust Cap: A cap that covers the outer end of the wheel hub, protecting the wheel bearing from dust and contaminants.

Understanding these parts and their functions is essential for any car owner. Knowing the anatomy of your car’s wheels allows you to better understand maintenance needs, diagnose potential problems, and communicate effectively with mechanics when service is required.

FAQs

What Are The Main Parts of A Car Wheel Assembly?

The primary parts of a car wheel assembly are the tire, the rim, and the hub. The tire provides grip and cushioning, the rim supports the tire, and the hub connects the wheel to the vehicle.

What is The Part Of The Car Body Above The Wheel Called?

The part of the car body directly above the wheel is called the fender or wheel arch. Fenders protect the vehicle and pedestrians from debris thrown up by the tires and contribute to the vehicle’s aerodynamics.

What Secures A Wheel To A Car?

Wheels are secured to the car using wheel studs (or wheel bolts) and lug nuts (or wheel bolts). Wheel studs are mounted to the hub, and lug nuts tighten against the wheel to hold it firmly in place.

What Are The Basic Components Of A Car Wheel?

The basic components of a car wheel include the tire, rim, and hub. These are the foundational parts that make up the wheel assembly, with other parts like spokes, barrel, and valve stem contributing to their function and design.

What Are Components Of A 4-Wheel Drive System Related To Wheels?

While not directly parts of the wheel itself, components of a 4-wheel drive system related to wheels include the drive shafts that transmit power to each wheel, and the differential, which allows wheels to rotate at different speeds when cornering. These systems work in conjunction with the wheels to enable four-wheel drive capability.

By familiarizing yourself with this Diagram Of Car Wheel Parts and their descriptions, you’re now better equipped to understand and maintain one of the most crucial systems on your vehicle.