For any car owner or DIY mechanic, understanding your vehicle’s health is crucial. Thankfully, modern vehicles are equipped with sophisticated onboard diagnostic systems, primarily OBD-II, that can pinpoint problems before they escalate. The key to unlocking this diagnostic information lies in understanding Error Code Obd2, also known as Diagnostic Trouble Codes (DTCs). When your car’s computer detects an issue, it stores a DTC in its memory, accessible through the OBD port. By using an OBD-II scanner, you can retrieve these codes and gain valuable insights into your car’s condition. This article will serve as your comprehensive guide to understanding and interpreting OBD2 error codes, empowering you to diagnose and address car problems effectively.

Understanding the Structure of OBD2 Error Codes

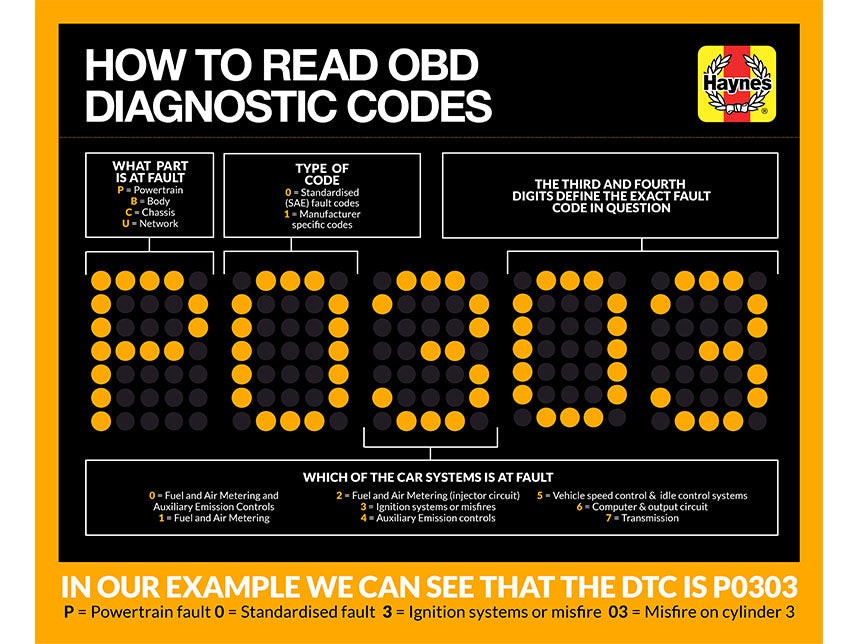

OBD2 error codes are not random strings of characters. They follow a standardized format that allows you to quickly identify the general area and nature of the problem. Each code is composed of five characters: one letter followed by four numbers. Let’s break down each component:

The First Letter: Identifying the Fault Category

The first letter of an OBD2 code indicates the primary system affected by the fault. There are four main categories:

- P (Powertrain): This is the most common category and relates to issues within the engine, transmission, and related drivetrain components. Think of problems with fuel delivery, ignition, exhaust, or emission control systems.

- B (Body): Body codes refer to issues with the car’s body systems, such as power windows, airbags, central locking, and comfort or convenience features.

- C (Chassis): Chassis codes relate to problems with the car’s structural and running gear, including braking systems (ABS), steering, and suspension.

- U (Network): Network or communication codes indicate problems within the car’s communication network, often involving the Controller Area Network (CAN bus) and issues with data transmission between different electronic control units (ECUs).

The First Number: Standardized vs. Manufacturer Specific Codes

The first number following the letter further refines the code classification:

- 0 (Standardized/Generic): A ‘0’ indicates a standardized or generic OBD2 code. These codes are defined by the Society of Automotive Engineers (SAE) and are common across all vehicle manufacturers. This means a P0XXX code will generally have the same meaning regardless of whether you drive a Ford, Toyota, or BMW.

- 1 (Manufacturer-Specific): A ‘1’ in this position signifies a manufacturer-specific code. These codes are defined by the specific car manufacturer and may have different meanings or troubleshooting procedures compared to generic codes. For example, a P1XXX code for a Honda might indicate a different issue than the same code on a Chevrolet. Always consult your vehicle’s repair manual or a manufacturer-specific database when dealing with these codes.

The Second Number: Pinpointing the Subsystem

The second number (the third character in the entire code) narrows down the specific vehicle subsystem that is experiencing the fault. The categories are generally as follows:

- 0: Fuel and Air Metering and Auxiliary Emission Controls: This category covers issues related to the air-fuel mixture, oxygen sensors, mass airflow sensors, and components that manage emissions.

- 1: Fuel and Air Metering: Focuses specifically on fuel and air metering systems, excluding auxiliary emission controls.

- 2: Fuel and Air Metering (Injector Circuit): Specifically relates to problems within the fuel injector circuits.

- 3: Ignition Systems or Misfires: Indicates issues with the ignition system, such as spark plugs, ignition coils, or engine misfires.

- 4: Auxiliary Emission Controls: Deals with secondary emission control systems like evaporative emission (EVAP) systems or secondary air injection systems.

- 5: Vehicle Speed Control & Idle Control Systems: Covers issues with systems that regulate vehicle speed (cruise control) and engine idle speed.

- 6: Computer & Output Circuit: Relates to problems within the vehicle’s computer (ECU/PCM) and its output circuits that control various actuators.

- 7: Transmission: Indicates faults within the automatic transmission system.

The Third and Fourth Numbers: Specifying the Exact Fault

The final two digits (the fourth and fifth characters) provide the most specific information, pinpointing the exact nature of the fault within the identified subsystem. These numbers are simply sequential and used to differentiate between various faults within each category. For example, within the ‘Ignition Systems or Misfires’ (category 3), codes like P0301, P0302, P0303, etc., each indicate a misfire on a specific cylinder (cylinder 1, cylinder 2, cylinder 3, etc.).

Decoding an Example: Error Code P0303

Let’s take the example P0303 to illustrate how to decode an OBD2 error code:

- P: Indicates a Powertrain fault, meaning the issue is related to the engine or transmission system.

- 0: Signifies a standardized or generic OBD2 code, applicable across different manufacturers.

- 3: Points to the ‘Ignition systems or misfires’ subsystem.

- 03: Specifically identifies a misfire on cylinder 3.

Therefore, the error code P0303 tells you that your vehicle’s computer has detected a misfire on cylinder number 3. This information allows you to focus your diagnostic efforts on the ignition system components related to cylinder 3, such as the spark plug, ignition coil, or fuel injector.

OBD II trouble code structure

OBD II trouble code structure

Common OBD2 Error Codes and Their Meanings

While there are thousands of possible OBD2 error codes, some are more common than others. Understanding these frequently encountered codes can be particularly helpful. Here is a chart of some common OBD2 trouble codes and their general descriptions:

| Code | Code Identification |

|---|---|

| P0101 | Mass air flow (MAF) sensor circuit, range or performance problem |

| P0102 | Mass air flow (MAF) sensor circuit, low input |

| P0103 | Mass air flow (MAF) sensor circuit, high input |

| P0106 | Manifold absolute pressure (MAP) sensor circuit, range or performance problem |

| P0107 | Manifold absolute pressure (MAP) sensor circuit, low input |

| P0108 | Manifold absolute pressure (MAP) sensor circuit, high input |

| P0112 | Intake air temperature (IAT) circuit, low input |

| P0113 | Intake air temperature (IAT) circuit, high input |

| P0117 | Engine coolant temperature (ECT) circuit, low input |

| P0118 | Engine coolant temperature (ECT) circuit, high input |

| P0121 | Throttle position sensor (TPS) circuit, range or performance problem |

| P0122 | Throttle position sensor (TPS) circuit, low input |

| P0123 | Throttle position sensor (TPS) circuit, high input |

| P0125 | Insufficient coolant temperature for closed loop fuel control |

| P0131 | Oxygen sensor circuit, low voltage (pre-converter sensor, left bank) |

| P0132 | Oxygen sensor circuit, high voltage (pre-converter sensor, left bank) |

| P0133 | Oxygen sensor circuit, slow response (pre-converter sensor, left bank) |

| P0134 | Oxygen sensor circuit – no activity detected (pre-converter sensor, left bank) |

| P0135 | Oxygen sensor heater circuit malfunction (pre-converter sensor, left bank) |

| P0137 | Oxygen sensor circuit, low voltage (post-converter sensor, left bank) |

| P0138 | Oxygen sensor circuit, high voltage (post-converter sensor, left bank) |

| P0140 | Oxygen sensor circuit – no activity detected (post-converter sensor, left bank) |

| P0141 | Oxygen sensor heater circuit malfunction (post-converter sensor, left bank) |

| P0143 | Oxygen sensor circuit, low voltage (#2 post-converter sensor, left bank) |

| P0144 | Oxygen sensor circuit, high voltage (#2 post-converter sensor, left bank) |

| P0146 | Oxygen sensor circuit – no activity detected (#2 post-converter sensor, left bank) |

| P0147 | Oxygen sensor heater circuit malfunction (#2 post-converter sensor, left bank) |

| P0151 | Oxygen sensor circuit, low voltage (pre-converter sensor, right bank) |

| P0152 | Oxygen sensor circuit, high voltage (pre-converter sensor, right bank) |

| P0153 | Oxygen sensor circuit, slow response (pre-converter sensor, right bank) |

| P0154 | Oxygen sensor circuit – no activity detected (pre-converter sensor, right bank) |

| P0155 | Oxygen sensor heater circuit malfunction (pre-converter sensor, right bank) |

| P0157 | Oxygen sensor circuit, low voltage (post-converter sensor, right bank) |

| P0158 | Oxygen sensor circuit, high voltage (post-converter sensor, right bank) |

| P0160 | Oxygen sensor circuit – no activity detected (post-converter sensor, right bank) |

| P0161 | Oxygen sensor heater circuit malfunction (post-converter sensor, right bank) |

| P0171 | System too lean, left bank |

| P0172 | System too rich, left bank |

| P0174 | System too lean, right bank |

| P0175 | System too rich, right bank |

| P0300 | Engine misfire detected |

| P0301 | Cylinder number 1 misfire detected |

| P0302 | Cylinder number 2 misfire detected |

| P0303 | Cylinder number 3 misfire detected |

| P0304 | Cylinder number 4 misfire detected |

| P0305 | Cylinder number 5 misfire detected |

| P0306 | Cylinder number 6 misfire detected |

| P0307 | Cylinder number 7 misfire detected |

| P0308 | Cylinder number 8 misfire detected |

| P0325 | Knock sensor circuit malfunction |

| P0327 | Knock sensor circuit, low output |

| P0336 | Crankshaft position sensor circuit, range or performance problem |

| P0337 | Crankshaft position sensor, low output |

| P0338 | Crankshaft position sensor, high output |

| P0339 | Crankshaft position sensor, circuit intermittent |

| P0340 | Camshaft position sensor circuit |

| P0341 | Camshaft position sensor circuit, range or performance problem |

| P0401 | Exhaust gas recirculation, insufficient flow detected |

| P0404 | Exhaust gas recirculation circuit, range or performance problem |

| P0405 | Exhaust gas recirculation sensor circuit low |

| P0410 | Secondary air injection system |

| P0418 | Secondary air injection pump relay control circuit |

| P0420 | Catalyst system efficiency below threshold, left bank |

| P0430 | Catalyst system efficiency below threshold, right bank |

| P0440 | Evaporative emission control system malfunction |

| P0441 | Evaporative emission control system, purge control circuit malfunction |

| P0442 | Evaporative emission control system, small leak detected |

| P0446 | Evaporative emission control system, vent system performance |

| P0452 | Evaporative emission control system, pressure sensor low input |

| P0453 | Evaporative emission control system, pressure sensor high input |

| P0461 | Fuel level sensor circuit, range or performance problem |

| P0462 | Fuel level sensor circuit, low input |

| P0463 | Fuel level sensor circuit, high input |

| P0500 | Vehicle speed sensor circuit |

| P0506 | Idle control system, rpm lower than expected |

| P0507 | Idle control system, rpm higher than expected |

| P0601 | Powertrain Control Module, memory error |

| P0602 | Powertrain Control module, programming error |

| P0603 | Powertrain Control Module, memory reset error |

| P0604 | Powertrain Control Module, memory error (RAM) |

| P0605 | Powertrain Control Module, memory error (ROM) |

Disclaimer: Not all codes apply to all models. Always consult your vehicle’s service manual for specific diagnostic procedures.

Using an OBD2 Scanner to Retrieve Error Codes

To access these valuable OBD2 error codes, you’ll need an OBD2 scanner. These scanners are readily available and range from basic handheld devices to more advanced professional-grade tools. Here’s a general process for using an OBD2 scanner:

- Locate the OBD2 Port: The OBD2 port is typically located under the dashboard on the driver’s side of most vehicles. Consult your car’s manual if you’re unsure of its exact location.

- Plug in the Scanner: With the ignition off, plug the OBD2 scanner into the port.

- Turn Ignition to ‘ON’ (Engine Off): Turn the ignition key to the ‘ON’ position, but do not start the engine. This provides power to the car’s computer and the OBD2 system.

- Power On the Scanner and Follow Instructions: Turn on the OBD2 scanner and follow the manufacturer’s instructions to connect to the vehicle’s computer and read diagnostic trouble codes. Most scanners have a ‘Read Codes’ or similar function.

- Record and Interpret the Codes: The scanner will display any stored error codes. Record these codes and use the information in this article and other resources to understand their meaning and potential causes.

- Troubleshooting and Repair: Based on the error codes and your understanding of their implications, begin troubleshooting and repairing the identified issues.

- Clear the Codes (After Repair): Once you have addressed the problem, you can use the OBD2 scanner to clear the error codes. This will turn off the check engine light. However, it’s essential to ensure the underlying issue is resolved; otherwise, the code may reappear.

Conclusion: Empowering Car Owners with OBD2 Error Code Knowledge

Understanding error code OBD2 is a powerful tool for any car owner or enthusiast. It allows for proactive vehicle maintenance, quicker diagnosis of problems, and potentially significant savings on repair costs by enabling DIY fixes or providing informed insights when consulting with a professional mechanic. By learning to decode these codes and utilizing OBD2 scanners, you take a significant step towards becoming a more informed and empowered car owner, capable of understanding and maintaining your vehicle’s health effectively.