Calculating fuel flow using OBD2 data can be a complex task, especially when direct sensor readings aren’t available. Many car enthusiasts and professionals rely on OBD2 data for diagnostics and performance monitoring, but sometimes the ideal sensors aren’t supported by the vehicle’s system. This article explores the challenges of calculating Fuel Flow Over Obd2, focusing on indirect methods and potential pitfalls when direct Parameter IDs (PIDs) are unavailable.

One of the most straightforward methods for monitoring fuel flow would be to use PID 015E, dedicated to “Fuel Flow Rate.” However, as many have discovered, including myself during a recent project, this PID isn’t universally supported across all vehicle makes and models. Facing this limitation, the next logical step is often to turn to the Mass Air Flow (MAF) sensor, accessible via PID 0110. Unfortunately, support for this PID can also be inconsistent, leaving us searching for alternative solutions to estimate fuel flow indirectly.

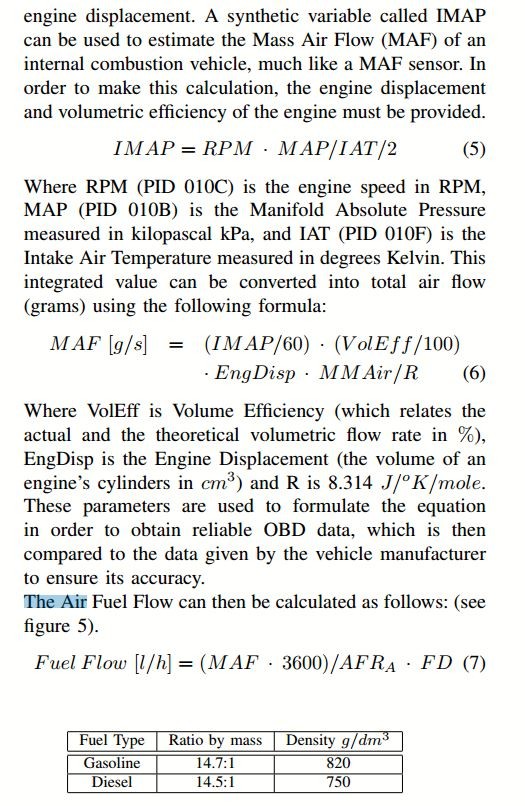

This is where the Manifold Absolute Pressure (MAP) sensor comes into play. Several online resources and research papers suggest that MAP readings can be leveraged to derive MAF, and subsequently, fuel flow. The principle is based on the relationship between manifold pressure, engine speed, and air density to estimate the mass of air entering the engine. Links such as OBD2 Guru – IMAP & AF Calculation and guides like the one found in the obdgpslogger project on GitHub outline formulas for this indirect calculation. Academic research, such as the paper “Assessing the impact of driving behavior on instantaneous fuel consumption,” further explores various methodologies for MAF estimation.

My own attempts to implement these formulas, however, yielded unrealistic results. Calculations based on MAP and assumed volumetric efficiency produced fuel flow rates in the order of gallons per second – a figure far exceeding expected values. For instance, using a formula derived from the research paper, as shown below, I encountered this issue:

The implemented code, based on this formula, looked like this:

IMAP = (engineRPM * absolutePress) / ((airTemp + 273) / 2f);

MAF = (IMAP / 60) * (volumetricEff / 100f) * (engineDisp / 1000f) * (28.97f / 8.314f);

fuelFlow = (MAF * 3600) / (14.7f * 820) ; // l/hDespite careful unit conversions (engine displacement to liters, temperature to Kelvin), the resulting fuel flow was drastically high. A key parameter in these calculations is “volumetric efficiency,” which I initially estimated at 70-80%. The significant discrepancy suggests that either this assumed value is incorrect, or there are other factors at play.

Interestingly, apps like “Torque” are capable of calculating and displaying believable fuel flow rates on the same vehicle under similar conditions. Torque’s output, around 0.000066 gallons/sec, seemed much more plausible. This indicates that indirect fuel flow calculation via OBD2 is indeed possible, but the accuracy heavily depends on the method and parameters used. While contacting the Torque app developer for insights proved unsuccessful, exploring alternative formulas and a more accurate method for determining volumetric efficiency becomes crucial.

The research paper referenced earlier also presented another, more complex formula for MAF calculation, which purportedly bypasses the need for volumetric efficiency. This formula, depicted below, appears more intricate and potentially harder to implement directly:

While the goal isn’t necessarily pinpoint accuracy, achieving a believable fuel flow estimation is essential for many OBD2-based applications. Further investigation into accurate volumetric efficiency determination or the implementation of more robust formulas, like the one above, is needed to bridge the gap between theoretical calculations and real-world OBD2 fuel flow data. For those working on similar projects, a deeper dive into these alternative methods and careful validation against known benchmarks, such as the Torque app readings, will be key to unlocking reliable fuel flow estimation over OBD2.