Supply chain disruptions have become a familiar aspect of modern life, and while some sectors are recovering, the automotive industry continues to face significant challenges, particularly with car part availability. For car owners, this translates to frustrating delays when vehicles require repairs. Dayna Welch experienced this firsthand with her brand new 2024 Honda HR-V. Barely after making her third payment, a leak led her to discover a radiator issue, only to be met with the news that the necessary part was on critical backorder. This situation raises a crucial question for many drivers: just How Long Can Car Parts Be On Backorder, and what can be done in the meantime?

The reality is that there’s no definitive answer to how long car parts can be on backorder. The duration can vary widely depending on the specific part, the vehicle manufacturer, and the nature of the supply chain bottleneck at any given time. Deborah Robinson, Executive Director of the National Auto Body Council, points out that the automotive parts supply chain is still recovering from the ripple effects of the COVID-19 pandemic, compounded by ongoing labor shortages and factory shutdowns. This creates a perfect storm, leaving countless vehicles awaiting essential components to get back on the road.

The reasons behind these backorders are multifaceted. Global supply chain issues are a primary driver, impacting the availability of raw materials and the manufacturing and transportation of parts. Labor shortages further exacerbate the problem, slowing down production lines and logistics. Even when parts are manufactured, logistical hurdles can delay their arrival at dealerships and repair shops. This complex web of issues means that a simple radiator, like the one Dayna Welch needed, or more complex electronic components can be caught in limbo, leading to indefinite wait times.

For car owners, this uncertainty can be incredibly stressful. Being without a vehicle disrupts daily life, impacting work, family commitments, and overall independence. As Dayna Welch emotionally shared, facing a car repair issue as a single parent already struggling after a previous car accident amplifies the hardship. The financial strain of ongoing lease payments for a non-operational car, coupled with potential rental car expenses, adds another layer of burden.

American Honda acknowledged these challenges in a statement, highlighting the “unprecedented global supply chain challenges affecting multiple automakers and industries.” They emphasized their efforts to resolve backorders and recommended customers work closely with local dealerships to prioritize critical part orders. However, this statement also underscores the industry-wide nature of the problem and the lack of immediate, guaranteed solutions.

So, what can you do if you find yourself in a similar situation, facing the frustrating reality of car parts on backorder? While there’s no magic bullet to instantly resolve supply chain issues, there are proactive steps you can take to mitigate the impact and potentially expedite your repair.

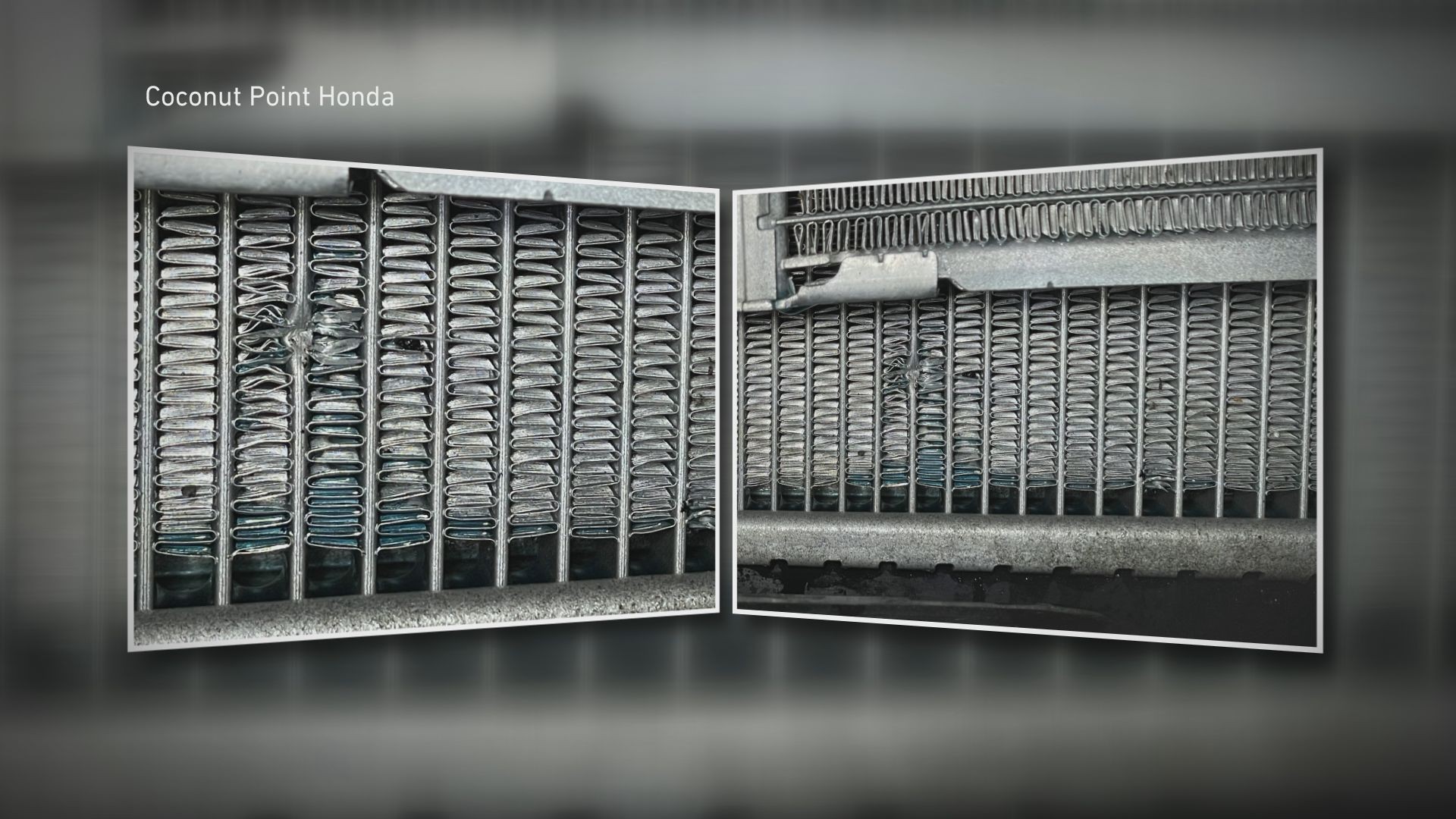

1. Communicate and Inquire: Maintain open communication with your dealership or repair shop. Ask for regular updates on the estimated backorder time for your specific part. Don’t hesitate to inquire if there are any alternative solutions or if they can check with other dealerships within their network, as Honda of Fort Myers did for Dayna Welch by sourcing a radiator from a used vehicle.

2. Explore Warranty and Insurance Coverage: Review your car’s warranty to understand what repairs are covered and if rental car assistance is included. Similarly, check your auto insurance policy. As the original article advises, ensuring rental car coverage and roadside assistance in your policy can be invaluable if you face extended repair delays due to backordered parts.

3. Shop Around Strategically: If your primary dealership is facing a significant backorder, it’s worth contacting other dealerships or reputable repair shops in your area. As Deborah Robinson from the National Auto Body Council suggests, what’s unavailable at one location might be accessible at another. Expanding your search can sometimes uncover a quicker solution.

4. Consider Aftermarket Parts (with Caution): In some cases, aftermarket parts might be available sooner than original equipment manufacturer (OEM) parts. However, exercise caution and discuss this option thoroughly with your repair shop. Ensure the aftermarket part is of comparable quality and reliability and won’t void any warranties. For critical components like radiators or braking systems, OEM parts are generally recommended for optimal performance and safety.

5. Plan Ahead and Be Proactive: While you can’t predict breakdowns, being prepared can lessen the stress of car part backorders. Establish a relationship with a trusted auto body shop before you need them. Keep their contact information handy in case of emergencies. Having a roadside assistance plan ensures you’re not stranded if a breakdown occurs.

Navigating car part backorders requires patience, persistence, and proactive communication. While the duration of these delays can be unpredictable, understanding the underlying causes and taking strategic steps can help you minimize downtime and get back on the road as quickly as possible. Remember to leverage your network of dealerships and repair professionals, explore all available options, and ensure you have adequate warranty and insurance coverage to protect yourself from unexpected repair delays.