Diagnosing modern vehicle issues can be complex, even with the aid of technology. Connecting an OBD2 scanner is straightforward, but truly understanding the diagnostic trouble codes (DTCs), especially those related to emissions, requires more than just reading the code itself. Freeze frame data, recorded when a DTC is triggered, is intended to provide a snapshot of the engine’s operating conditions at the moment of the fault. However, relying solely on this data can be misleading. Often, the key to effective diagnosis lies not just in what the freeze frame data reveals, but in what it doesn’t tell you.

This guide will delve into the intricacies of OBD2 freeze frame data and equip you with the knowledge to effectively assess this information. We’ll explore what freeze frame data is, how to interpret it, and, crucially, how to recognize its limitations to avoid misdiagnosis and ensure accurate automotive repairs.

Understanding OBD2 Freeze Frame Data

The term “freeze frame” itself is quite descriptive. When your vehicle’s On-Board Diagnostics II (OBD2) system detects a fault severe enough to potentially illuminate the Check Engine Light (CEL), it captures and stores a set of critical engine parameters. This recording occurs at the precise moment the fault is first registered during the initial of two consecutive driving cycles (trips) where the fault is detected. Think of freeze frame data as a snapshot in time – a single frame capturing the engine’s state when the problem arose.

This data is stored in the vehicle’s computer memory alongside the corresponding DTC. It remains there until the code is cleared after a repair or if the vehicle’s battery is disconnected. However, it’s important to note that if a higher priority fault occurs – one that could potentially cause more significant damage, such as to the catalytic converter or engine – the original freeze frame data might be overwritten by the data associated with the more critical new fault.

Freeze frame data isn’t just a single value; it’s composed of several layers of information, all combined into a retrievable message accessible via most OBD2 scan tools. Let’s break down some typical components:

Similar Conditions Window: This section provides context about the engine’s operation when a readiness monitor is running. It typically records Manifold Absolute Pressure (MAP) values and engine speed if a failure prevents a monitor from completing its test. There are separate Similar Conditions Windows for the fuel system and misfire detection. For fuel system failures, the system records MAP and engine speed to assess if the fuel delivery strategy aligned with engine load and speed at the time of failure.

Adaptive Memory Factor: This parameter reflects the ECU’s calculation of total fuel corrections needed over time using both short-term and long-term fuel trim values. This ensures emissions control compliance by monitoring overall fuel consumption within designed limits.

Similar Conditions Time Window: This tracks the duration the engine runs without failures, as long as “Similar Conditions” are met. Each successful, failure-free trip increments a “good trip” counter.

Fuel System Good Trip Counter: Specifically for fuel system related DTCs, this counter plays a role in extinguishing the CEL. A “good trip” requires the “Similar Conditions Window” to indicate “YES,” and the “Adaptive Memory Factor” to remain below a predefined threshold for a set period.

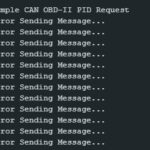

Image: A technician using an OBD2 scanner to read freeze frame data, highlighting the importance of this step in automotive diagnostics.

Deciphering Freeze Frame Data: What Parameters to Look For

Beyond the core layers described above, typical freeze frame data often encompasses a broader range of parameters. The specific data points available depend on the capabilities of your scan tool and the vehicle’s make and model. Common parameters you might encounter include:

- Engine Coolant Temperature (ECT): Crucial for understanding engine operating temperature at the time of the fault.

- Intake Air Temperature (IAT): Indicates the temperature of the air entering the engine.

- Fuel Pressure: Provides information about the fuel delivery system’s pressure.

- Throttle Position Sensor (TPS) values/Throttle Opening Angle: Reflects the throttle position and driver demand.

- Oxygen Sensor Voltages: Essential for evaluating the air-fuel mixture and catalytic converter efficiency.

- Engine Run-Time Since Code Set: Indicates how long the engine had been running since the DTC was first registered.

- Vehicle Speed (VSS): Shows the vehicle’s speed when the fault occurred.

- Fuel Trim (Short Term and Long Term): Indicates the ECU’s fuel adjustments to maintain the correct air-fuel ratio.

- Mass Air Flow (MAF) Rate: Measures the amount of air entering the engine.

- RPM (Engine Speed): Engine speed at the time of the fault.

- Calculated Engine Load: Percentage representing the engine’s workload.

- Ignition Timing Advance: Timing of the spark plug firing.

Interpreting Freeze Frame Data: Case Studies and Practical Examples

While freeze frame data presents a wealth of information, its true diagnostic power emerges when you understand how to interpret it within the context of the specific DTC and vehicle symptoms. Often, the most insightful clues are found not in the data itself, but in what’s conspicuously absent. Let’s examine two common DTCs, P0420 (Catalyst System Efficiency Below Threshold Bank 1) and P0300 (Random/Multiple Cylinder Misfire Detected), to illustrate this point.

Case Study 1: P0420 – Catalyst System Efficiency Below Threshold Bank 1

In this scenario, a generic OBD2 scanner retrieved freeze frame data for a Ford vehicle with a P0420 code. No other DTCs were present, and the driver reported no noticeable driveability issues. Here’s the relevant freeze frame data:

- Fuel SYS 1 CL: Closed Loop operation – fuel system regulating based on sensor feedback.

- Fuel SYS 2 N/A: Non-V engine (single bank).

- Load (%) 92.1: High engine load, typical for normal operation.

- ECT (0C) 101.6: Normal operating temperature.

- Shrt FT 1 (%) 2.2: Slight positive short-term fuel trim.

- Long FT 1 (%) -3.1: Negative long-term fuel trim, indicating the ECU is removing fuel.

- MAP (kPa) 26.7: Low manifold pressure, suggesting idle or light load.

- RPM (min) 2035: Moderate engine speed.

- VSS (k/ph) 74: Vehicle moving at speed.

- IAT (0C) 28: Ambient intake air temperature.

Analysis and Diagnostic Approach:

At first glance, the data seems unremarkable, failing to pinpoint a clear cause for the P0420 code. The negative long-term fuel trim suggests a rich condition, which seems counterintuitive for a catalyst efficiency code. However, a critical observation is the absence of crucial data: fuel pressure and oxygen sensor data are missing from this freeze frame.

This absence is a significant clue. Without oxygen sensor readings, we can’t directly assess catalytic converter performance. Condemning the catalytic converter based solely on this limited freeze frame data would be premature and potentially incorrect.

Given the rich indication (negative fuel trim) and the lack of oxygen sensor data, further investigation is warranted. Since no oxygen sensor DTCs were present, the rich condition likely stems from a factor the ECU cannot directly monitor or control.

The Missing Piece: Vehicle History and Further Inspection

Experienced technicians know that a thorough diagnostic process often includes questioning the vehicle owner about recent events. In this case, questioning revealed a recent engine overheating incident.

Subsequent inspection of the spark plugs revealed oil fouling, indicating potential piston ring or cylinder wall damage due to overheating. This explains the rich condition: oil entering the combustion chamber was being interpreted by the ECU as excess fuel, leading to negative fuel trim adjustments. Exhaust gas analysis confirmed high hydrocarbon levels from oil consumption.

Resolution: In this example, the freeze frame data, while initially inconclusive, directed the diagnostic process towards considering factors outside the directly monitored parameters. The lack of oxygen sensor data and the rich indication, combined with vehicle history, pointed to internal engine damage as the root cause, not simply a faulty catalytic converter. Engine replacement or rebuild was recommended.

Case Study 2: P0300 – Random/Multiple Cylinder Misfire Detected

A Mercedes GLK 280 with a P0300 code presented with a cold start misfire. The misfire subsided as the engine warmed up. A high-end scan tool captured the following freeze frame data:

- Fuel System 1 Status = 1 & Fuel System 2 Status = 1: Closed loop operation on both banks.

- Calculated Load = 22.16 %: Low engine load.

- Engine coolant temperature = 87 deg C: Warm engine temperature (despite complaint of cold start misfire, data taken after engine warmed up).

- Short term fuel trim (Bank 1) = 0% & Short term fuel trim (Bank 2) = 0%: Zero short-term fuel trim on both banks.

- Long term fuel trim (Bank 1) = +11.65% & Long term fuel trim (Bank 2) = +7.4%: Positive long-term fuel trim, indicating lean condition, with a significant difference between banks.

- Vehicle speed = 0 km/h: Vehicle at idle.

- Ignition advance (Cyl #1) = 42.0 deg: Normal ignition timing.

- Engine speed = 1198.1 RPM: Elevated idle speed.

- IAT = 38 deg C: Ambient intake air temperature.

- Mass airflow rate = 5.60 gram/second: Low airflow at idle.

- Absolute throttle position = 12.8%: Slightly open throttle at idle.

- Fuel pressure (Rail) = 379 kPa: Normal fuel pressure.

- Commanded EVAP Purge = 0%: EVAP system not active.

- Fuel level = 42.1%: Fuel level in tank.

- Control module current = 13.90 V: System voltage normal.

- Various Throttle/Accelerator Pedal Position Parameters: Consistent readings.

- Commanded air/fuel equivalence ratio = 1.53: Lean commanded air-fuel ratio (values > 1 indicate lean).

Analysis and Diagnostic Approach:

Again, the freeze frame data is rich in parameters but lacks a direct explanation for the misfire, especially considering the engine temperature is already warm in the freeze frame. However, several anomalies stand out:

- Zero Short-Term Fuel Trim: With the engine at 87°C, upstream oxygen sensors should be in closed-loop operation, and short-term fuel trims should be actively fluctuating, not fixed at 0%. This strongly suggests a problem with the upstream oxygen sensors.

- Significant Long-Term Fuel Trim Imbalance: The large difference in long-term fuel trim between bank 1 (+11.65%) and bank 2 (+7.4%) indicates a potential imbalance in air-fuel mixture between the cylinder banks.

The Diagnostic Path: Oxygen Sensors and Vacuum Leak

The zero short-term fuel trim values strongly pointed to faulty upstream oxygen sensors. Live data confirmed this: both sensors showed a constant 1.0V signal, indicating they were unresponsive.

However, replacing the oxygen sensors alone wouldn’t explain the long-term fuel trim imbalance. A systemic lean condition causing misfires during cold starts and the bank-to-bank fuel trim difference suggested a vacuum leak.

Verification and Resolution: Penetrating oil applied around the intake manifold revealed a vacuum leak, most pronounced on bank 1. As the engine warmed, manifold expansion sealed the leak, resolving the misfire. Replacing the intake manifold gaskets permanently fixed the issue.

Image: Example of diagnostic information, possibly from a scan tool or repair manual, emphasizing the need for comprehensive data interpretation.

Conclusion: Freeze Frame Data as Part of the Diagnostic Puzzle

These examples highlight a critical lesson: freeze frame data is a valuable tool, but it’s not a standalone solution for automotive diagnostics. Over-reliance on potentially incomplete freeze frame data can lead to misdiagnosis, wasted parts, and dissatisfied customers.

Key Takeaways for Assessing Freeze Frame Data OBD2:

- Understand What’s Missing: Pay attention to parameters not included in the freeze frame data. Missing oxygen sensor data, fuel pressure, or other crucial readings can be as informative as the data present.

- Context is Key: Interpret freeze frame data in conjunction with the specific DTC, vehicle symptoms, and vehicle history.

- Don’t Jump to Conclusions: Freeze frame data provides clues, not definitive answers. Use it to guide further testing and investigation.

- Consider External Factors: Think beyond the directly monitored parameters. Vacuum leaks, mechanical issues, and vehicle history can significantly impact diagnostic outcomes.

- Utilize Live Data: Supplement freeze frame data with live data streaming from sensors to observe real-time engine operation and confirm suspicions.

- Experience Matters: Experienced technicians develop an intuition for recognizing patterns and anomalies in freeze frame data, enabling more efficient and accurate diagnoses.

By mastering the art of assessing freeze frame data – understanding its strengths and limitations – you can elevate your diagnostic skills and provide more effective and reliable automotive repairs. Remember, freeze frame data is a snapshot; a comprehensive diagnosis requires examining the entire picture.