In an era where environmental consciousness and sustainable practices are no longer optional but essential, electric vehicles (EVs) have surged into the limelight. Their promise of reduced emissions, enhanced efficiency, and lower running costs compared to traditional combustion engine vehicles is capturing the attention of drivers globally. Beyond just environmental benefits, the allure of cheaper “fuel” – electricity versus gasoline or diesel – and the exciting possibilities of vehicle electrification are propelling the EV market and the innovative sector of electric car conversions to new heights.

The concept of breathing new life into classic cars through electrification is gaining traction. It’s now more economically viable and practically achievable than ever before to convert a gasoline or diesel vehicle into an electric powerhouse. Instead of opting for a brand-new EV model, many are turning to electric car conversions, replacing outdated engines and transmissions with cutting-edge batteries and electric motors.

Thinking about converting your own car to electric? It’s an exciting venture, but understanding the fundamental differences between EVs and their combustion engine counterparts is key. To demystify this transition, we’ll delve into the core components and functionalities of an electric car conversion, revealing what makes these vehicles tick and, crucially, what constitutes the Most Important Part Of An Electric Car.

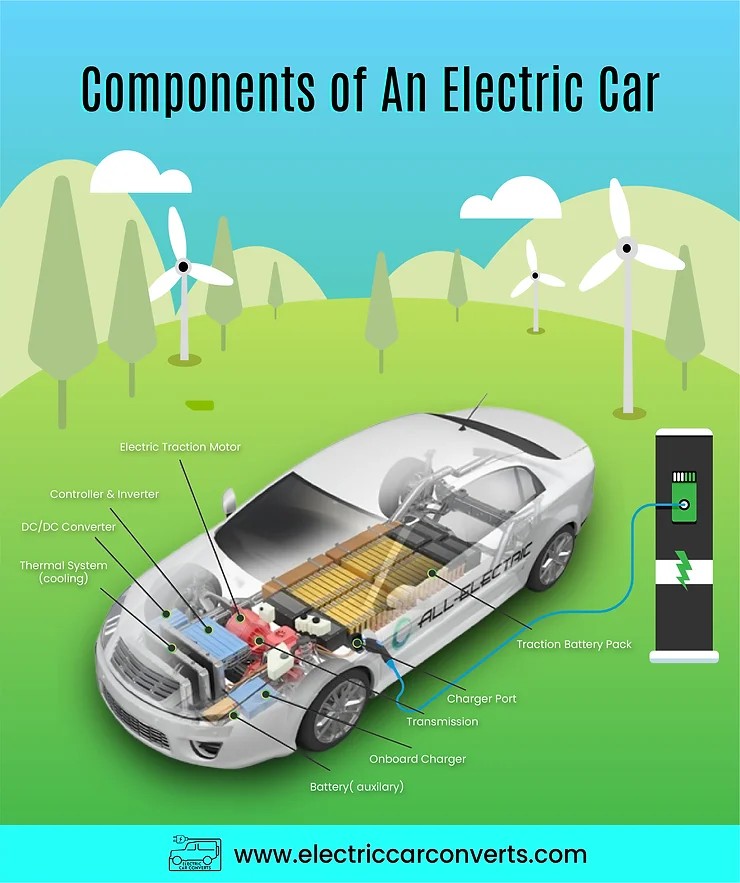

Understanding How Electric Cars Work: A Symphony of Components

Unlike traditional cars powered by internal combustion engines, electric cars are driven by electric motors. These motors draw their power from high-voltage battery packs, with the amount of electricity supplied dictated by the accelerator pedal.

Here’s a breakdown of the process when you press the accelerator in an EV:

- The Motor Controller (Inverter): Acting as the central nervous system, the controller receives the signal from the accelerator and calculates the precise power demand from the battery pack.

- Power Delivery: The inverter then channels the required electrical energy to the electric motor, adjusting the flow based on the accelerator input.

- Energy Conversion: Within the motor, electrical energy is ingeniously transformed into mechanical (rotational) energy using electromagnets and wire coils.

- Transmission Engagement: The motor’s output shaft rotates within the transmission system.

- Wheel Propulsion: The transmission modulates this rotation into a usable speed for the drivetrain (axles, differentials, driveshafts), ultimately turning the wheels and propelling the vehicle forward.

Key Components of an Electric Car: Identifying the “Most Important Part”

While every component plays a vital role in the seamless operation of an electric car, some stand out due to their significance in performance, range, and overall functionality. Let’s examine these key components to determine which might be considered the “most important”.

Battery Pack: The Heart of the Electric Vehicle

Many argue that the battery pack is the most critical component of an EV. It’s undeniably the largest and often the most expensive part, directly dictating the vehicle’s power and driving range. A typical battery pack comprises numerous interconnected batteries, ranging from 5 to 25 modules, each containing hundreds of individual cells – often repurposed from production EVs to promote sustainability and cost-effectiveness in conversions.

These battery modules are carefully housed within a robust, custom-built metal battery box, designed to fit snugly into the original engine bay of a converted classic vehicle. For extended range requirements, a secondary battery box can be added, often placed in the trunk or under the rear seats.

The battery box is not just a housing; it’s an integrated system containing essential electronics for managing and monitoring the entire pack. This includes an ignition system to control power flow and, crucially, a Battery Management System (BMS). The BMS is the guardian of the battery, constantly monitoring voltage, temperature, and current during charging and discharging cycles. It’s vital for preventing damage from overheating or overvoltage, ensuring optimal battery health and longevity.

Furthermore, the battery box incorporates a sophisticated cooling system, featuring an external radiator and water pump. This system circulates coolant through each battery within the pack, maintaining uniform temperature and preventing overheating, which could otherwise limit motor output and battery lifespan.

Given its role in energy storage, range determination, and overall performance, the battery pack is a strong contender for the title of the “most important part of an electric car.”

Power Inverter/Controller: Orchestrating Power Delivery

The power inverter, also known as the motor controller, acts as a crucial intermediary between the battery pack and the electric motor. Its primary function is to convert direct current (DC) from the batteries into alternating current (AC), which is the type of electricity required by most EV motors. Think of it as the conductor of an orchestra, coordinating the flow of power to the motor. Without it, the motor would simply operate at full capacity continuously, offering no modulation or control.

The motor controller is intricately linked to the vehicle’s throttle and the battery management system. It interprets the driver’s acceleration commands and communicates with the BMS to ensure efficient and safe power delivery.

Due to the high current flow, especially during rapid acceleration, inverters are also integrated with the battery cooling system. This cooling mechanism prevents overheating and maintains optimal operating temperatures.

Adding another layer of functionality, modern inverters facilitate regenerative braking. During deceleration, the inverter can reverse the power flow, converting kinetic energy back into electrical energy and feeding it back to the battery, thus enhancing efficiency and range.

The inverter’s role in power conversion, control, and regenerative braking positions it as another critically important component in an electric car.

Electric Motor: The Driving Force

The electric motor is the component responsible for converting electrical energy into the mechanical energy that propels the car. Motors come in various types, with some running on DC and others on AC. AC motors are favored for EV conversions due to their superior efficiency. An electric motor essentially functions as a large, precisely controlled electromagnet, generating motion through the principles of magnetic attraction and repulsion.

Electric motors are remarkably efficient, converting over 85% of electrical energy into mechanical energy, a stark contrast to the less than 40% efficiency of a gasoline combustion engine. (Source: NRDC.org)

Electric motors vary significantly in size and power output. A motor suitable for a classic car conversion might produce around 120 horsepower, while high-performance motors, like those in Tesla vehicles, can exceed 500 horsepower.

The motor’s rotational force is directed to the transmission (gearbox). Conversions often retain the original gearbox to minimize costs and complexity, requiring only adapter plates for motor integration. Alternatively, single-speed transmissions designed specifically for electric power can be used. However, integrating high-performance motors like Tesla drive units often necessitates custom drivetrain modifications, increasing conversion costs.

Other Essential Components in an Electric Vehicle: Supporting Systems

Beyond the battery, inverter, and motor, several other components are crucial for the overall functionality and user experience of an EV.

Charger: Replenishing the Energy Source

An EV charger is a sophisticated device that converts AC power from the grid into DC power to recharge the vehicle’s batteries. Onboard chargers are “smart,” carefully managing the charging process to optimize battery health and charging speed.

Mounted within the car, the charger allows for convenient charging at home, public charging stations, or service areas.

Charging power varies significantly, impacting charging time. Standard household outlets offer slower charging (2-3kWh), while dedicated wall-mounted units or public charging stations can deliver 10kWh or more, significantly reducing charging times. For home charging solutions, companies like Go Electrik, partners with Electric Car Converts, offer expert installation services.

DC/DC Converter: Powering Auxiliary Systems

The DC/DC converter is essential for stepping down the high-voltage DC power from the main battery pack to the standard 12V DC needed to operate the car’s conventional 12V systems. This includes lights, wipers, central locking, and other standard car electronics. This clever component eliminates the need for extensive rewiring of the car’s 12V system during conversion, saving considerable cost and complexity.

Thermal System (Cooling): Maintaining Optimal Temperatures

Despite their high efficiency, EVs still generate some heat. To protect components and ensure optimal performance, a thermal management system is essential. While some parts are air-cooled, critical components like the batteries and inverter require liquid cooling.

The thermal system comprises a small radiator, a fan, a coolant pump, and coolant lines, forming a closed-loop system to dissipate heat from sensitive components.

The electric car cooling system’s key elements are:

- Radiator: Dissipates heat from the coolant fluid.

- Coolant: Transfers heat away from EV components.

- Fan: Enhances air circulation through the radiator, especially in slow-moving traffic.

Charging Port: The Gateway to Energy

The charging port, often located where the fuel filler used to be, provides the external connection to the car’s charging system, allowing for easy battery replenishment.

In the UK and Europe, Type 2 plugs are standard for EV conversions, ensuring compatibility with public charging infrastructure. While fast charging stations are readily available, it’s also possible to charge an EV conversion using a standard 3-pin socket, albeit at a slower rate. Electric Car Converts’ battery packs can charge from empty to full in about 8 hours using a standard plug, or just 4 hours with a dedicated wall-mounted charging station.

The Real “Most Important Part”: A Holistic View

While the battery pack arguably holds immense significance due to its impact on range and power, declaring a single “most important part” of an electric car is an oversimplification. In reality, the “most important part” is the entire integrated system. Each component, from the battery to the charging port, works in synergy to deliver a functional, efficient, and enjoyable electric driving experience.

However, if we were to single out a component that underpins the current EV revolution and future advancements, it would likely be the battery technology. Continued innovation in battery technology – increasing energy density, reducing costs, improving charging speeds, and enhancing lifespan – is paramount to making EVs more accessible, practical, and sustainable for the masses.

Electric Car Converts: Pioneering the Electric Future

Electric vehicles represent the future of personal transportation. For EVs to fully replace gasoline cars, continuous advancements in technology and a shift in mindset are essential. As technology evolves, electric cars are poised to become increasingly affordable and mainstream. Understanding the various components that power these vehicles is crucial for drivers embracing this electric transition.

We at Electric Car Converts are dedicated experts in all facets of EV conversions. If you’re intrigued by the possibilities of converting your car to electric, we’re here to answer your questions and guide you on your journey into the electric future!

Reviewed by Barnaby Birkbeck (Founder) & Toby Wilson (Head Electrical Engineer), in 2025.

This article is for general informational purposes, reviewed for accuracy by our experts. Consult us for personalized advice.