Just like the human heart is essential for life, the engine is undeniably the heart of your motor car. Its primary function is to convert fuel energy into motion, enabling you to drive. This process, known as internal combustion, involves a series of controlled, miniature explosions that generate the power needed to move your vehicle. While often perceived as a single unit, a motor car engine is a complex assembly of numerous interconnected components working in perfect harmony. You might recognize some Motor Car Engine Parts names, but understanding their specific roles and interactions is crucial for vehicle maintenance and longevity.

Essential Motor Car Engine Parts and Their Functions

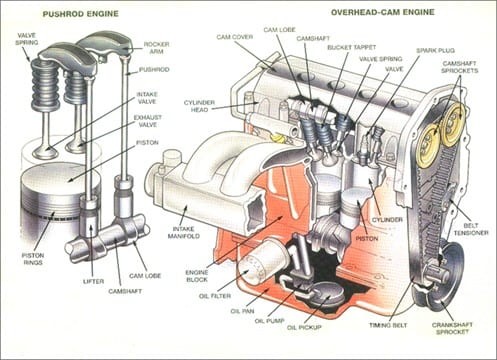

Detailed view of a car engine's internal components

Detailed view of a car engine's internal components

Modern motor car engines are built around robust, sealed metal cylinders. The number of these cylinders typically ranges from four to eight in most contemporary vehicles, although some high-performance models can feature up to sixteen cylinders. These cylinders are meticulously designed to open and close at precise intervals, facilitating the intake of fuel for combustion and the expulsion of exhaust gases. Let’s delve into some of the most vital motor car engine parts and explore their functions, using the accompanying diagram as a visual guide.

Engine Block: The Foundation

The engine block serves as the structural backbone of the engine. Usually crafted from aluminum or iron, it’s engineered with cylindrical bores to house the cylinders. Crucially, it incorporates intricate internal passages for coolant and oil circulation, essential for engine temperature regulation and lubrication. Oil pathways are designed to be narrower than coolant passages. The engine block also provides housing for key motor car engine parts such as the pistons, crankshaft, and camshaft, and accommodates the cylinders – typically four to twelve – arranged in inline, flat, or V configurations depending on the vehicle.

Pistons: The Energy Translators

Pistons are cylindrical components featuring a flat top surface. Their primary function is to convert the energy released during combustion into mechanical force, which is then transferred to the crankshaft to propel the vehicle. Within each cylinder, pistons move up and down twice for every crankshaft rotation. In engines operating at 1250 RPM, pistons endure an impressive 2500 up and down cycles per minute. Piston rings, located within the piston grooves, play a vital role in maintaining cylinder compression and minimizing friction caused by the piston’s constant movement against the cylinder walls, ensuring efficient operation of motor car engine parts.

Crankshaft: Converting Linear to Rotational Motion

Positioned in the lower section of the engine block within crankshaft journals (bearing surfaces), the crankshaft is a precisely engineered and balanced component. It connects to the pistons via connecting rods. Much like a jack-in-the-box mechanism, the crankshaft transforms the pistons’ linear up-and-down motion into rotational motion at engine speed. This rotational force is what ultimately powers the vehicle’s drivetrain.

Camshaft: Orchestrating Valve Timing

The camshaft’s location varies across different vehicles; it can be situated within the engine block or in the cylinder heads. Many modern motor cars utilize cylinder head placement, often employing Dual Overhead Camshaft (DOHC) or Single Overhead Camshaft (SOHC) configurations. Supported by oil-lubricated bearings for durability, the camshaft’s role is to precisely manage the timing of valve opening and closing. It converts the crankshaft’s rotary motion into an up-and-down motion, controlling lifters, pushrods, rockers, and ultimately, the valves. This precise timing is critical for the intake of air and fuel and the expulsion of exhaust gases, ensuring the efficient functioning of motor car engine parts.

Cylinder Head: The Control Center

Attached to the engine block with cylinder bolts and sealed with a head gasket, the cylinder head is a complex component. It houses numerous parts including valve springs, valves, lifters, pushrods, rockers, and camshafts. Its design incorporates intake passages that allow air to enter the cylinders during the intake stroke, and exhaust passages for removing combustion gases during the exhaust stroke. The cylinder head is crucial for controlling the flow of gases in and out of the combustion chamber, a vital aspect of motor car engine parts operation.

Timing Belt/Chain: Synchronization is Key

To ensure proper engine operation, the camshaft and crankshaft must be synchronized for precise timing. This synchronization is achieved by either a timing belt or a timing chain. A timing belt is constructed from durable rubber with cogs that mesh with pulleys on the camshaft and crankshaft. A timing chain, similar to a bicycle chain, wraps around toothed pulleys. Both components ensure the valves open and close in perfect coordination with piston movement, which is essential for efficient combustion and overall engine performance of motor car engine parts.

Common Motor Car Engine Problems

With so many intricate motor car engine parts operating at high speeds, wear and tear over time is inevitable. This can lead to various engine problems, often manifesting in changes in your car’s behavior. Here are some common engine issues and their associated symptoms:

- Poor Compression: This results in reduced engine power, misfires, or even a no-start condition.

- Cracked Engine Block: A cracked block can cause engine overheating, exhaust smoke, or coolant leaks, often visible on the engine’s exterior.

- Damaged Pistons, Rings, and/or Cylinders: Symptoms include rattling noises, blue exhaust smoke, rough idling, or failure to pass emissions tests.

- Broken or Worn Rods, Bearings, & Pins: These issues can cause tapping or ticking sounds, low oil pressure, metal particles in the engine oil, or rattling sounds during acceleration.

While motor car engines may appear intricate, their fundamental task is straightforward: to propel your vehicle. With so many motor car engine parts working in concert to generate motion, regular and proper vehicle maintenance is paramount for ensuring their longevity. Routine oil changes, fluid flushes, and timely replacement of belts and hoses are essential preventative measures against major engine failures. For expert care and maintenance of your motor car engine parts, seeking a reputable service center is always a wise decision.