Navigating car troubles can be daunting, but modern vehicles offer a significant advantage for car owners and DIY mechanics alike: the On-Board Diagnostics II (OBD2) system. This system acts as your car’s internal health monitor, and when something goes wrong, it communicates the issue through Diagnostic Trouble Codes (DTCs). By understanding how to read these codes using an OBD2 scanner and consulting an Obd2 Code Chart, you can gain valuable insight into your vehicle’s problems and take informed steps towards repair.

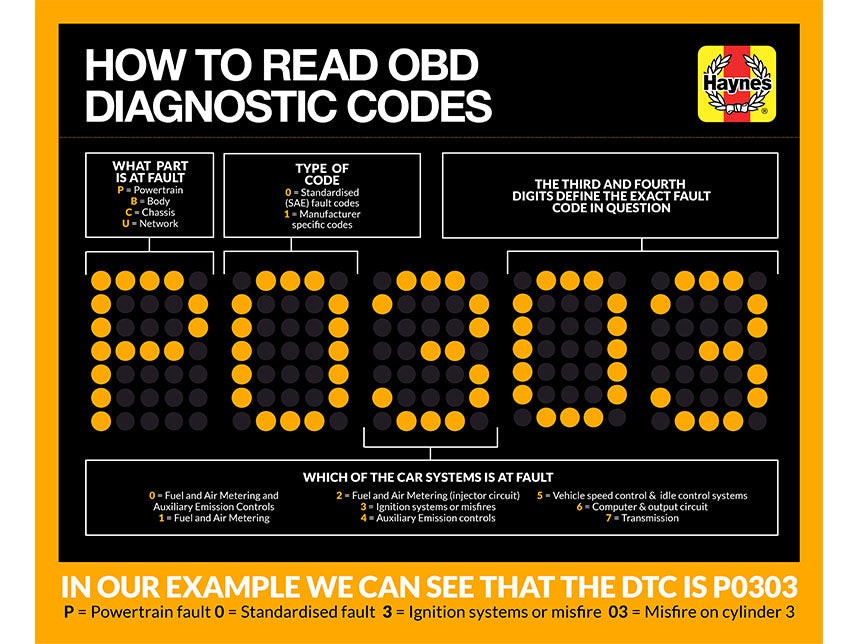

When your car’s computer, the Engine Control Unit (ECU), detects a problem, it stores a specific DTC in its memory. These codes aren’t random; they follow a structured format, making it easier to understand the general area and nature of the fault even before consulting a detailed chart. Let’s break down the anatomy of an OBD2 code.

Cracking the Code: Understanding the Structure of DTCs

Every OBD2 code is composed of five characters: one letter followed by four numbers. Each position in the code provides crucial information about the problem.

1. The First Letter: Category of the Fault

The initial letter of the code indicates the primary system affected:

- P (Powertrain): This is the most common category and relates to issues with the engine, transmission, and related drivetrain components.

- B (Body): Body codes refer to problems within the car’s body systems, such as airbags, power windows, and central locking.

- C (Chassis): Chassis codes indicate issues with the chassis systems, including braking, steering, and suspension.

- U (Network): Network or communication codes pertain to problems with the vehicle’s communication network, like the Controller Area Network (CAN) bus.

2. The First Number: Code Type

The first number following the letter specifies whether the code is standardized or manufacturer-specific:

- 0: Indicates a standardized or generic OBD2 code. These codes are defined by the Society of Automotive Engineers (SAE) and are common across most vehicle makes and models.

- 1: Denotes a manufacturer-specific code. These codes are defined by the car manufacturer and are unique to specific brands or models. While the general category is indicated by the letter, a manufacturer-specific code provides more detailed information relevant to that particular vehicle.

3. The Second Number: Subsystem Affected

The second number pinpoints the specific vehicle subsystem experiencing the fault within the broader category defined by the first letter. For Powertrain (P) codes, these numbers represent:

- 0: Fuel and Air Metering and Auxiliary Emission Controls

- 1: Fuel and Air Metering

- 2: Fuel and Air Metering (Injector Circuit)

- 3: Ignition Systems or Misfires

- 4: Auxiliary Emission Controls

- 5: Vehicle Speed Control & Idle Control Systems

- 6: Computer & Output Circuit

- 7: Transmission

4 & 5. The Third and Fourth Numbers: Specific Fault

The final two digits provide a precise identification of the fault within the subsystem. These numbers pinpoint the exact component or circuit malfunctioning. For example, in the code P0303, the “03” specifies a misfire on cylinder number 3.

Let’s take the example DTC P0303 to illustrate:

- P: Powertrain fault (engine or transmission related)

- 0: Standardized SAE code

- 3: Ignition system or misfire issue

- 03: Specific fault – misfire detected on cylinder 3

This breakdown allows for a logical approach to diagnosing car problems. By understanding the structure, you can use an OBD2 code chart more effectively to pinpoint the issue.

What are… Diagnostic Trouble Codes

What are… Diagnostic Trouble Codes

Understanding Diagnostic Trouble Codes and OBD2 System

Your Essential OBD2 Code Chart for Common Issues

Below is a simplified OBD2 code chart covering some common generic powertrain (P-codes) that you might encounter. Remember that this is not an exhaustive list, and manufacturer-specific codes will require more detailed resources. Always consult your vehicle’s repair manual or a comprehensive OBD2 database for complete information.

| Code | Code Identification |

|---|---|

| P0101 | Mass Air Flow (MAF) Sensor Circuit Range/Performance Problem |

| P0102 | Mass Air Flow (MAF) Sensor Circuit Low Input |

| P0103 | Mass Air Flow (MAF) Sensor Circuit High Input |

| P0106 | Manifold Absolute Pressure (MAP) Sensor Circuit Range/Performance Problem |

| P0107 | Manifold Absolute Pressure (MAP) Sensor Circuit Low Input |

| P0108 | Manifold Absolute Pressure (MAP) Sensor Circuit High Input |

| P0112 | Intake Air Temperature (IAT) Circuit Low Input |

| P0113 | Intake Air Temperature (IAT) Circuit High Input |

| P0117 | Engine Coolant Temperature (ECT) Circuit Low Input |

| P0118 | Engine Coolant Temperature (ECT) Circuit High Input |

| P0121 | Throttle Position Sensor (TPS) Circuit Range/Performance Problem |

| P0122 | Throttle Position Sensor (TPS) Circuit Low Input |

| P0123 | Throttle Position Sensor (TPS) Circuit High Input |

| P0125 | Insufficient Coolant Temperature for Closed Loop Fuel Control |

| P0131 | O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1) |

| P0132 | O2 Sensor Circuit High Voltage (Bank 1, Sensor 1) |

| P0133 | O2 Sensor Circuit Slow Response (Bank 1, Sensor 1) |

| P0134 | O2 Sensor Circuit No Activity Detected (Bank 1, Sensor 1) |

| P0135 | O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1) |

| P0137 | O2 Sensor Circuit Low Voltage (Bank 1, Sensor 2) |

| P0138 | O2 Sensor Circuit High Voltage (Bank 1, Sensor 2) |

| P0140 | O2 Sensor Circuit No Activity Detected (Bank 1, Sensor 2) |

| P0141 | O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 2) |

| P0171 | System Too Lean (Bank 1) |

| P0172 | System Too Rich (Bank 1) |

| P0300 | Random/Multiple Cylinder Misfire Detected |

| P0301 | Cylinder 1 Misfire Detected |

| P0302 | Cylinder 2 Misfire Detected |

| P0303 | Cylinder 3 Misfire Detected |

| P0304 | Cylinder 4 Misfire Detected |

| P0325 | Knock Sensor Circuit Malfunction |

| P0336 | Crankshaft Position Sensor Circuit Range/Performance |

| P0340 | Camshaft Position Sensor Circuit |

| P0401 | Exhaust Gas Recirculation (EGR) Insufficient Flow |

| P0420 | Catalyst System Efficiency Below Threshold (Bank 1) |

| P0440 | Evaporative Emission Control System Malfunction |

| P0500 | Vehicle Speed Sensor Circuit Malfunction |

| P0601 | Internal Control Module Memory Check Sum Error |

* Note: Not all codes are applicable to every vehicle model. Always refer to your vehicle’s service manual for specific diagnostic information.

By familiarizing yourself with the structure of OBD2 codes and using an OBD2 code chart, you can approach vehicle diagnostics with greater confidence. While this information is invaluable, remember that diagnosing and repairing modern vehicles can be complex. When in doubt, always consult a certified mechanic for professional assistance.