Since 1996, if you’re in the United States and own a car or light truck, it’s highly likely your vehicle is OBD-II compliant. While the mandate for OBD-II compliance in the US is relatively straightforward, the European Union’s OBD legislation presents a more complex landscape, as detailed in this article. But what exactly does OBD-II compliance mean, and how can you identify if your vehicle adheres to these standards? While a definitive “Obd2 Compliant Vehicles List Pdf” might not be readily available due to the vast number of compliant models, understanding the underlying protocols and standards is key to determining your vehicle’s status.

OBD-II compliance dictates that vehicles must support one of five communication protocols for diagnostic purposes. These protocols are:

- J1850 PWM (Pulse Width Modulation)

- J1850 VPW (Variable Pulse Width)

- ISO9141-2

- ISO14230-4 (Keyword Protocol 2000)

- ISO15765-4/SAE J2480 (CAN – Controller Area Network)

Notably, while US automakers were restricted from utilizing the CAN protocol until the 2003 model year, it became mandatory for all vehicles manufactured from 2008 onwards. This standardization of communication protocols is fundamental to OBD-II, enabling universal diagnostic tools to interface with a wide array of vehicles.

Diagnostic Link Connectors (DLCs): Type A and Type B

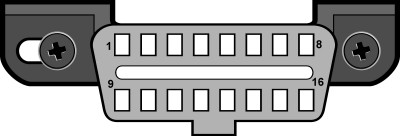

The physical interface for accessing the OBD-II system is the Diagnostic Link Connector (DLC). SAE J1962 standard defines two types of DLCs: Type A and Type B. The primary distinction between them lies in the alignment tab’s shape, ensuring proper connection.

Type A DLCs, as per J1962 specifications, are typically located within the passenger or driver’s compartment. The standard placement zone extends from the driver’s side of the instrument panel to approximately 300mm (1 foot) beyond the vehicle’s centerline. Ideally, it’s positioned between the steering column and the vehicle’s centerline for easy accessibility from the driver’s seat.

Figure 1 – J1962 Vehicle Connector, Type A

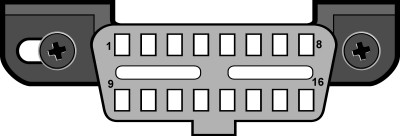

Type B DLCs offer more flexibility in location. They can be situated in the passenger or driver’s compartment, ranging from the driver’s instrument panel end, including the outer side, to an imagined line about 750mm (2.5 feet) beyond the vehicle centerline. These connectors are attached to the instrument panel and designed for easy access from the driver’s seat, co-driver’s seat, or even from outside the vehicle. The mounting of the vehicle connector is designed to facilitate both connection and disconnection.

Figure 2 – J1962 Vehicle Connector, Type B

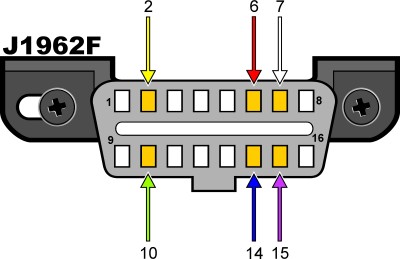

Decoding OBD2 Protocols Through Pinout

While the DLC type provides physical connection information, the pinout of the connector is crucial for determining the communication protocol your vehicle uses. By examining the pins present in your OBD-II connector, you can identify the protocol employed.

Figure 3 – J1962 OBDII Connector Pinout Diagram

The table below simplifies protocol identification based on pin presence:

| Pin 2 | Pin 6 | Pin 7 | Pin 10 | Pin 14 | Pin 15 | Standard |

|---|---|---|---|---|---|---|

| Must | – | – | Must | – | – | J1850 PWM |

| Must | – | – | – | – | – | J1850 VPW |

| – | – | Must | – | – | May* | ISO9141/14230 |

| – | Must | – | – | Must | – | ISO15765 (CAN) |

*Note: Pin 15 (L-line) may be optional in newer vehicles utilizing ISO9141-2 or ISO14230-4 protocols.

Irrespective of the protocol, every OBD-II compliant connector must include pins 4 (Chassis Ground), 5 (Signal Ground), and 16 (Battery Positive). This leads to the following pin configuration requirements for each protocol:

| Protocol | Required Pins |

|---|---|

| PWM | Pins 2, 4, 5, 10, and 16 |

| VPW | Pins 2, 4, 5, and 16, but not pin 10 |

| ISO | Pins 4, 5, 7, and 16 (Pin 15 may be present) |

| CAN | Pins 4, 5, 6, 14, and 16 |

While a direct “OBD2 compliant vehicles list pdf” may not be the most practical resource, understanding these protocols and connector specifications empowers you to determine OBD-II compliance for most vehicles manufactured for the US market post-1996. For further exploration into manufacturer-specific protocol implementation, resources like the OBDII Generic Communication Protocols by Manufacturer can provide additional insights. Remember to always consult your vehicle’s owner manual or manufacturer specifications for the most accurate information.