The OBD2 (On-Board Diagnostics II) connector, a seemingly simple 16-pin interface, is crucial for modern vehicle diagnostics and maintenance. Since 1996, every car manufactured has been equipped with one, designed to provide standardized access to vehicle data for emission control and diagnostics. This standardization is beneficial as it allows any generic OBD2 scanner to retrieve essential information from virtually any car, regardless of the manufacturer. However, it’s important to note that while the OBD2 standard mandates access to certain data points, automakers often incorporate a wealth of additional data beyond this standard, which might not be accessible with a basic scan tool.

Pin Layout of the OBD2 Connector

Understanding the pin layout is fundamental when dealing with Obd2 Connector Replacement. Here’s a breakdown of the standard pin assignments:

- Pin 1: Manufacturer Discretion

- Pins 2 & 10: SAE J1850 (Network Communication)

- Pin 3: Manufacturer Discretion

- Pin 4: Chassis Ground

- Pin 5: Signal Ground

- Pins 6 & 14: CAN Bus High and Low (Network Communication)

- Pins 7 & 15: ISO9140 K-Line (Network Communication)

- Pins 8, 9, 11, 12, 13: Manufacturer Discretion

- Pin 16: Battery Positive (Key Off Power)

Common Causes of OBD2 Connector Damage

Pin 16, the battery positive pin, is overwhelmingly the most frequently damaged component of the OBD2 connector. Several factors contribute to this vulnerability.

One common issue is a blown fuse associated with pin 16. This can occur due to poorly designed aftermarket accessories drawing excessive power from the port or an overload on a shared circuit. While a blown fuse itself won’t physically harm the connector, the subsequent troubleshooting attempts often do. Inexperienced individuals may resort to forceful probing of the connector with inappropriate tools, leading to terminal and connector damage. In fact, damage resulting from careless testing procedures is a leading cause necessitating OBD2 connector replacement.

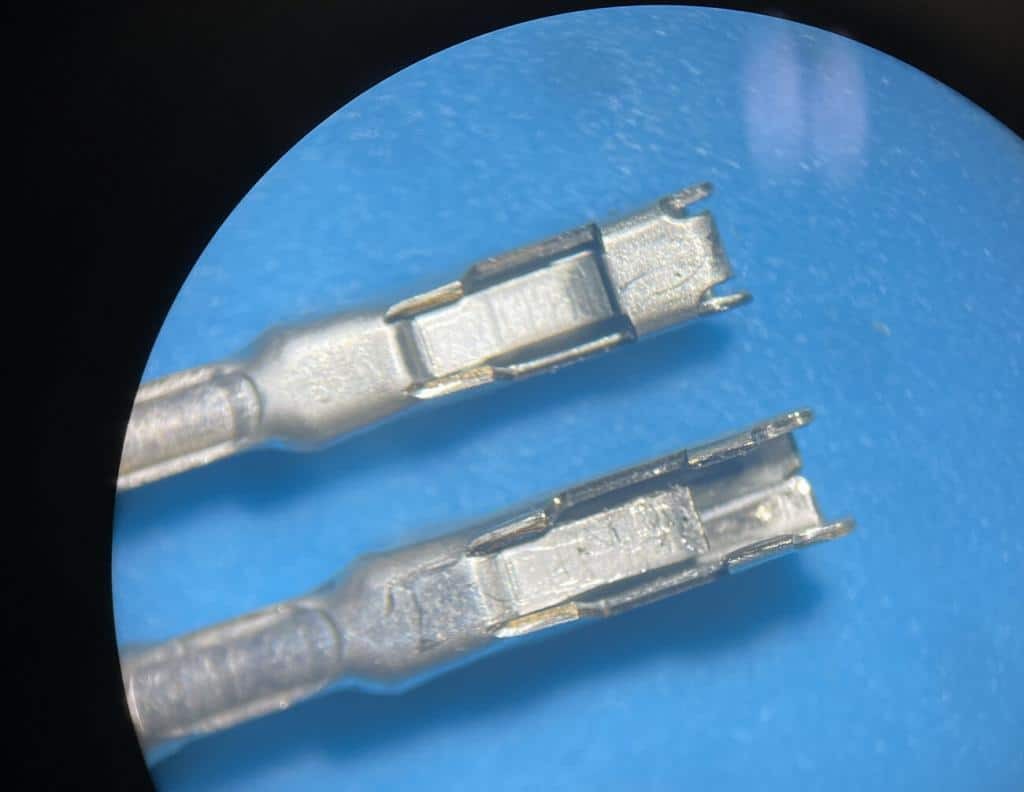

Another significant contributor is the growing popularity of aftermarket devices that utilize the OBD2 port. These include insurance telematics dongles, aftermarket gauges, and data logging devices. The issue here often stems from compromised engineering and quality control in some aftermarket products. Oversized male pins on these devices can stretch and distort the delicate female terminals within the OBD2 connector. Additionally, some devices may draw excessive and continuous current from pin 16, exceeding the connector’s intended design. The OBD2 port is designed to supply power intermittently to diagnostic tools, not to sustain high-current devices continuously while the vehicle is running.

The Myth of Universal OBD2 Connectors

Despite the OBD2 system being a standardized protocol, the connectors themselves are far from universally identical. While any standard male OBD2 connector will physically mate with any female OBD2 port in a vehicle, the similarities largely end there. The crucial differences lie in how the connector is mounted within the car’s interior and how the terminals are integrated into the connector housing. A quick consultation with any automotive connector supplier will reveal an extensive catalog of diverse connector bodies (the plastic housing) and terminals (the metal contacts), highlighting the lack of true standardization in the physical components.

The Pitfalls of Cheap Aftermarket OBD2 Connectors

The allure of inexpensive OBD2 connector replacements available online, often for as little as $12 on platforms like Amazon, can be strong. While these budget-friendly options might seem like a quick fix, they often present significant compromises. One immediate drawback is the mounting incompatibility. These universal connectors are rarely designed to fit the original vehicle’s mounting bracket. This necessitates resorting to makeshift mounting solutions, such as self-tapping screws directly into the lower dash, a solution that is both aesthetically unappealing and structurally questionable in terms of long-term durability.

However, mounting issues are secondary to the more critical problem of terminal quality. Low-cost aftermarket connectors frequently utilize inferior metals for their terminals. These metals often lack the necessary hardness and springiness of original equipment (OE) terminals. While installing such a connector might restore basic functionality, the longevity and reliability are severely compromised.

Consider the labor involved in an OBD2 connector replacement. Each terminal typically requires around 3 minutes for proper crimping and installation onto a pigtail wire. Accessing the vehicle’s wiring often necessitates removing lower dash panels, adding at least 15 minutes to the job, including reassembly. Soldering and heat-shrinking the typically 10 wires connected to an OBD2 connector will consume roughly 5 minutes per wire. Cumulatively, a seemingly simple OBD2 connector replacement can easily translate into 1.5 hours or more of labor. At prevailing labor rates, this can amount to over $200 in labor costs alone.

Given this significant labor investment, opting for substandard parts becomes a financially imprudent decision. The potential for premature failure and the associated warranty costs for repair shops, not to mention the inconvenience and repeat repair expenses for vehicle owners, far outweigh the marginal savings of using cheap components.

Sourcing OEM OBD2 Connector Parts from Dealerships

Opting for original equipment manufacturer (OEM) parts from a dealership represents the most reliable approach to OBD2 connector replacement. However, this path is often perceived as challenging due to parts availability and identification hurdles. Toyota serves as a representative example, given their significant market share.

If you were to inquire at a Toyota dealership for a “replacement OBDII connector,” you would likely be informed that it’s not sold as a standalone part. While technically true that a complete OBD2 connector assembly might not be listed in their parts catalog, the individual components – the connector housing and terminals – are indeed procurable, albeit in pieces. The key to identifying the correct part numbers lies within the vehicle’s electrical wiring diagrams, typically accessible through online service information systems like Toyota’s TIS (Technical Information System). By navigating to the OBD2 connector in the wiring diagram and clicking on the associated information icon (often an orange box), the part number for the plastic connector housing is usually revealed.

Interestingly, connector part number information is also present in older, pre-digital Toyota service manuals. Searching for “part number of connectors” within TIS can often lead to a document listing connector part numbers cross-referenced by wiring diagram codes.

However, obtaining the connector housing is only half the solution; the metal terminals are also essential. A real-world scenario involving a Gen3 Prius highlights the process. Upon contacting a Toyota dealership with the connector housing part number and vehicle application, determining the compatible terminal part number can still be a challenge, even for dealership personnel. In this instance, resourceful dealership staff, including a parts manager and a shop foreman, eventually identified the correct terminal part number, showcasing that persistence and internal dealership knowledge are crucial in sourcing these components.

Toyota OBD2 Repair Terminal Part Number

Through diligent effort, the correct Toyota OBD2 repair terminal part number for various models, including the Gen3 Prius, is often 82998-05010. It’s important to verify compatibility for specific vehicle models, but this part number serves as a valuable starting point for Toyota OBD2 connector terminal replacement.

The price of this individual terminal and pigtail assembly, often around $20 or more, might seem disproportionately high compared to the component’s apparent manufacturing cost. While factors like warehousing, distribution, and retail markup contribute to the price, it underscores the often-expensive nature of OEM automotive electrical components.

Exploring Connector Experts and Mouser for Alternatives

Beyond OEM dealerships, specialized suppliers like Connector Experts offer viable alternatives for OBD2 connector replacement parts. Connector Experts specializes in reproducing OE connectors and terminals. Their TERM86 terminal is reported to be a compatible and high-quality alternative for many applications, mirroring the quality of OE terminals in terms of metal hardness, springiness, and dimensions, but at a significantly lower cost. Notably, Connector Experts terminals are typically sold without pre-attached pigtail wires.

Mouser Electronics is another reputable source, carrying a broad inventory of automotive connectors and terminals. However, navigating Mouser’s extensive catalog to pinpoint the exact required part can be a more complex undertaking.

Essential Tools: Crimping OBD2 Terminals

Every automotive technician should possess a set of wire crimpers, although standard crimpers are often designed for larger, traditional automotive terminal sizes, typically starting at 18-gauge wire and larger. Successfully crimping the small, open-barrel terminals commonly found in OBD2 connectors necessitates specialized crimping tools. High-quality precision crimpers, such as those from Engineer, a Japanese manufacturer, are highly recommended. Despite their unassuming appearance, these crimpers are engineered to produce factory-quality crimps on delicate terminals, ensuring reliable electrical connections.

Related Resources for Automotive Electrical Repair Enthusiasts

For those interested in delving further into automotive electrical repairs, these related articles may be of interest:

Making Custom Battery Cables

Mice Short Circuit the High Voltage Battery on a Prius

Prius Combination Meter (Speedometer) Repair