Experiencing engine trouble and seeing the check engine light illuminate on your dashboard? If your OBD2 scan tool is showing the error code P2135, you’ve come to the right place. This code, known as “Throttle/Pedal Position Sensor/Switch A/B Voltage Correlation,” indicates a problem within your vehicle’s throttle or pedal position sensor system. As expert mechanics at carparteu.com, we’re here to guide you through understanding, diagnosing, and resolving this issue.

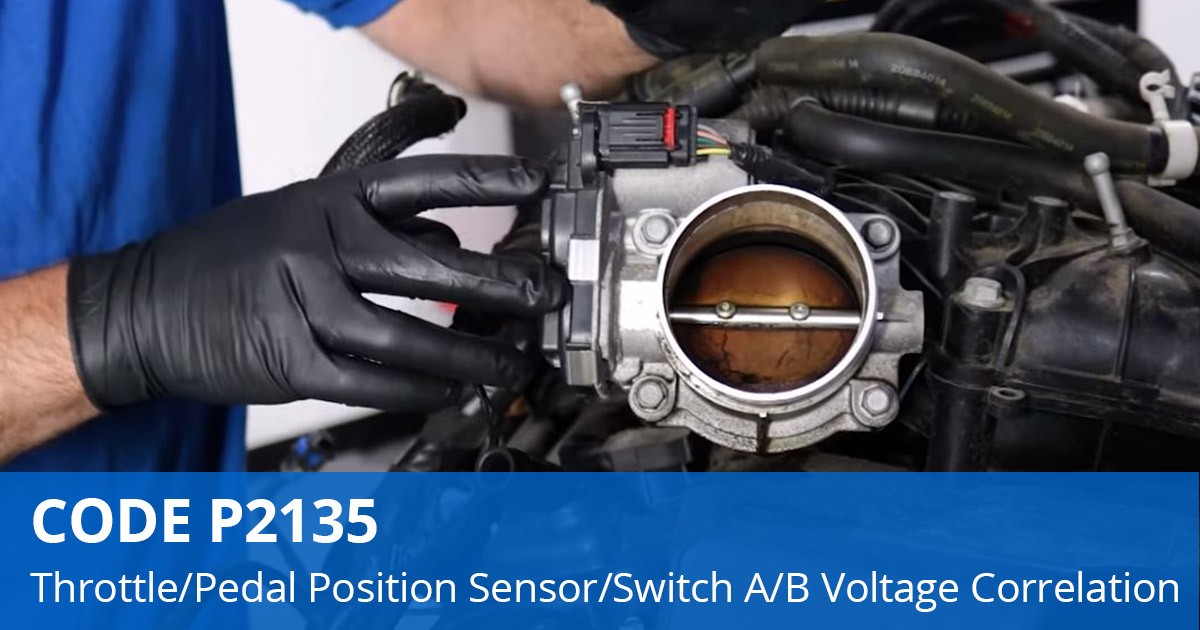

Throttle/Pedal position Sensor/Switch A/B Voltage Correlation for OBD2 P2135 Code

Throttle/Pedal position Sensor/Switch A/B Voltage Correlation for OBD2 P2135 Code

Decoding OBD2 Code P2135: Throttle/Pedal Position Sensor A/B Correlation Explained

The P2135 trouble code signifies that your car’s Powertrain Control Module (PCM), the central computer managing your engine and transmission, has detected a discrepancy in the voltage signals between the throttle position sensors (TPS) and/or the pedal position sensors (PPS). Modern vehicles use multiple sensors for redundancy and accuracy. Code P2135 specifically points to a voltage correlation problem between sensor ‘A’ and sensor ‘B’ within either the throttle position or pedal position sensor circuits.

To put it simply, the PCM expects consistent and related signals from these paired sensors. When the signals diverge beyond an acceptable threshold, the P2135 code is triggered, indicating a potential malfunction that needs your attention.

Understanding the Roles of Throttle and Pedal Position Sensors

To grasp the significance of the P2135 code, it’s crucial to understand the functions of the throttle position sensors and pedal position sensors within your vehicle’s engine management system.

Throttle Position Sensors (TPS)

Throttle position sensors are integral components of your engine’s air intake system. Located on the throttle body, these sensors monitor the position of the throttle blade. The throttle blade regulates the amount of air entering the engine. When you press the accelerator pedal, the throttle blade opens wider, allowing more air into the engine for increased power.

The TPS precisely measures the throttle blade’s angle and sends this data as voltage signals to the PCM. This information is vital for the PCM to calculate the correct air-fuel mixture and adjust engine performance accordingly. Modern vehicles often utilize two TPS units (sensor A and sensor B) for enhanced accuracy and fault detection.

Pedal Position Sensors (PPS)

Pedal position sensors, also known as accelerator pedal position sensors (APPS), are responsible for translating the driver’s foot input on the accelerator pedal into electronic signals. These sensors communicate to the PCM how much acceleration the driver is requesting.

Like TPS, PPS often come in pairs (sensor A and sensor B). They track the pedal’s movement and transmit voltage signals to the PCM, indicating the desired engine output. This input, combined with data from the TPS and other sensors, allows the PCM to control fuel injection and ignition timing for optimal engine performance.

Common Symptoms Associated with OBD2 Code P2135

When the PCM detects a voltage correlation issue between the throttle or pedal position sensors, it can manifest in various noticeable symptoms that affect your vehicle’s drivability. Recognizing these symptoms can help you quickly identify a potential P2135 code problem:

- Reduced Engine Power (Limp Mode): One of the most common symptoms is a significant decrease in engine power. The PCM may engage “limp mode” or “reduced power mode” to protect the engine from potential damage. In this mode, acceleration is severely limited, and the vehicle may struggle to reach higher speeds.

- Difficulty Accelerating: You might experience hesitation, sluggishness, or surging when pressing the accelerator pedal. The engine may not respond promptly to your input, making it difficult to accelerate smoothly.

- Engine Stalling: In some cases, the engine may stall, particularly after stopping or idling. This can be dangerous, especially in traffic.

- Unintended Engine Revving: Conversely, the engine RPMs might increase unexpectedly even when you are not pressing the gas pedal. This erratic behavior indicates a sensor malfunction.

- High Idle RPM: You may notice that the engine idles at a higher RPM than normal. This can contribute to increased fuel consumption and noise.

- Stuck Throttle: The throttle might become stuck at a certain RPM, meaning the engine speed remains constant regardless of pedal input.

- Check Engine Light: The most direct indicator is the illumination of the check engine light on your dashboard. This light signals that the PCM has detected a fault and stored a diagnostic trouble code, such as P2135.

If you observe any of these symptoms, especially in conjunction with a check engine light, it’s crucial to diagnose and address the issue promptly to avoid further complications and potential safety hazards.

Potential Causes of OBD2 Code P2135

Several factors can lead to the P2135 code. Pinpointing the exact cause is essential for effective repair. Here are the common culprits:

- Faulty Throttle Position Sensor (TPS) or Pedal Position Sensor (PPS): Sensor failure is the most frequent cause. Sensors can degrade over time, become contaminated, or suffer electrical malfunctions, leading to inaccurate voltage readings and triggering the P2135 code.

- Throttle Body Issues: Problems within the throttle body itself, such as carbon buildup, damage, or mechanical issues, can indirectly affect TPS readings and cause a P2135 code. A dirty throttle body can impede the smooth movement of the throttle plate.

- Wiring and Connector Problems: Electrical issues are common causes of sensor malfunctions. This includes:

- Disconnected Connectors: Loose or disconnected wiring connectors to the TPS or PPS can interrupt the signal flow.

- Corroded Terminals: Corrosion on the sensor or PCM connector terminals can increase resistance and disrupt signal integrity.

- Damaged Wiring: Faulty, frayed, shorted, or open wiring in the sensor circuits can lead to incorrect voltage readings.

- PCM Malfunction: Although less common, a faulty Powertrain Control Module (PCM) itself can misinterpret sensor signals or incorrectly trigger the P2135 code. PCM issues are usually diagnosed after ruling out other potential causes.

- Improper Dielectric Grease Application: While dielectric grease is used to protect electrical connections from corrosion, incorrect application, or using too much, can sometimes interfere with signal conductivity and contribute to sensor reading errors.

Diagnosing and Troubleshooting OBD2 Code P2135

Diagnosing the P2135 code requires a systematic approach. Here’s a step-by-step guide to help you pinpoint the root cause:

- OBD2 Scan and Code Verification: Use an OBD2 scan tool to confirm the presence of the P2135 code and check for any other related trouble codes. Record all codes present, as they can provide valuable clues.

- Visual Inspection: Carefully inspect the wiring and connectors associated with the TPS and PPS. Look for:

- Loose or disconnected connectors.

- Corrosion or damage on terminals.

- Frayed, cracked, or damaged wiring.

- Ensure the throttle body is clean and free from excessive carbon buildup.

- Sensor Testing (Multimeter): Use a multimeter to test the voltage, resistance, and continuity of the TPS and PPS circuits. Refer to your vehicle’s service manual for specific test procedures and expected values.

- Voltage Test: Check the sensor reference voltage and signal voltage. Compare readings between sensor A and sensor B to identify discrepancies.

- Resistance Test: Measure sensor resistance to check for internal sensor faults.

- Continuity Test: Verify wiring continuity to rule out open circuits or shorts.

- Throttle Body Inspection and Cleaning: Inspect the throttle body for carbon buildup or damage. Clean the throttle body using a throttle body cleaner and a soft brush, following the manufacturer’s recommendations.

- PCM Testing (Advanced): PCM testing is usually a last resort and often requires specialized equipment and expertise. If you suspect a PCM issue after ruling out other causes, consult a professional mechanic or automotive electronics specialist.

Resolving OBD2 Code P2135: Fixes and Solutions

The appropriate fix for a P2135 code depends on the underlying cause identified during diagnosis. Here are common solutions:

- Sensor Replacement: If testing reveals a faulty TPS or PPS, replacement is usually necessary. Replace the defective sensor with a high-quality replacement part. Ensure proper installation and connection.

- Wiring and Connector Repair: Address any wiring or connector issues identified during inspection. This may involve:

- Cleaning corroded terminals.

- Repairing or replacing damaged wiring.

- Securing loose connectors.

- Throttle Body Cleaning or Replacement: If the throttle body is excessively dirty, thorough cleaning may resolve the issue. In cases of damage or wear, throttle body replacement might be required.

- PCM Repair or Replacement (Rare): If a PCM malfunction is confirmed, repair or replacement by a qualified technician is necessary. PCM programming may be required after replacement.

Important Note: After performing any repairs, clear the P2135 code using an OBD2 scan tool and test drive the vehicle to ensure the code does not return and the symptoms are resolved.

Maintaining Your Vehicle to Prevent P2135 and Related Issues

Preventive maintenance plays a key role in minimizing the risk of OBD2 code P2135 and ensuring the longevity of your vehicle’s engine management system. Regular maintenance practices include:

- Regular Throttle Body Cleaning: Periodically clean the throttle body to prevent carbon buildup, which can affect TPS performance.

- Wiring Inspection: During routine maintenance, inspect engine wiring harnesses and connectors for any signs of damage, wear, or corrosion. Address any issues promptly.

- Professional Check-ups: Schedule regular professional vehicle inspections to identify potential problems early, including sensor issues or wiring concerns.

By understanding OBD2 code P2135, its symptoms, causes, and diagnostic procedures, you can effectively address this issue and maintain your vehicle’s optimal performance. If you’re not comfortable performing these repairs yourself, always seek assistance from a certified mechanic.

Related Resources

Explore our extensive library of how-to videos and articles for expert guidance on diagnosing and repairing various automotive issues. Learn more about throttle position sensors and pedal position sensors at 1A Auto.

Disclaimer: This article is for informational purposes only and should not be considered professional mechanical advice. Always consult a qualified mechanic for diagnosis and repair.