The On-Board Diagnostics II (OBD2) port is an essential interface in modern vehicles, serving as the gateway for accessing crucial vehicle data. Located within reach from the driver’s seat, this standardized 16-pin connector allows mechanics and car owners to diagnose problems, monitor performance, and ensure their vehicles are running optimally. While OBD2 port repair might seem straightforward, finding the correct replacement parts and executing a reliable fix can be more complex than anticipated. This guide provides comprehensive information to navigate the intricacies of Obd2 Port Replacement, ensuring a durable and effective repair.

Understanding the OBD2 Connector

Since 1996, every car manufactured has been equipped with an OBD2 connector. This standardization is a boon, enabling any generic OBD2 scanner to retrieve a baseline set of diagnostic information, regardless of the vehicle manufacturer. However, it’s important to note that while the OBD2 standard mandates access to specific data points, automakers often include a wealth of proprietary data beyond this standard. Consequently, generic scan tools might not access the full spectrum of information available through the OBD2 port.

Pin Configuration of the OBD2 Port

The OBD2 port is defined by a standardized pinout, ensuring compatibility across vehicles. Here’s a breakdown of the function of each pin:

- Pin 1: Manufacturer Discretion

- Pins 2 & 10: SAE J1850 network (communication protocol)

- Pin 3: Manufacturer Discretion

- Pin 4: Chassis Ground

- Pin 5: Signal Ground

- Pins 6 & 14: CAN bus High and Low (Controller Area Network communication)

- Pins 7 & 15: ISO 9141-2 K-Line (International Organization for Standardization communication)

- Pins 8, 9, 11, 12, 13: Manufacturer Discretion

- Pin 16: Battery Positive Power (constant power supply)

Common Causes of OBD2 Port Damage

Pin 16, which provides battery power, is frequently the victim of damage. There are primary reasons for this vulnerability:

Firstly, the fuse protecting pin 16 can sometimes blow. This could be triggered by poorly designed aftermarket accessories drawing excessive power from the port or an overload in a shared circuit. While a blown fuse itself doesn’t harm the connector terminal, misguided attempts to test for power using inappropriate probes can physically damage the terminal and potentially the entire connector. In fact, damage from careless testing is a leading cause necessitating OBD2 connector repair.

Secondly, the increasing popularity of aftermarket devices that utilize the OBD2 port, such as insurance telematics dongles, performance gauges, and data loggers, contributes to port wear and tear. While these accessories offer appealing features, their quality control and engineering can sometimes fall short of OEM standards. Issues arise from oversized male pins on these devices, which can stretch and damage the female terminals within the OBD2 connector. Another problem is devices that draw excessive current continuously from pin 16. The OBD2 port is designed to supply power intermittently to scan tools, not to sustain high-current devices constantly while the vehicle is running.

The Myth of Universal OBD2 Connectors

Despite the OBD2 standard, connectors are not universally identical in terms of physical mounting and terminal installation. While any standard male OBD2 connector can physically plug into any female OBD2 port, the method of securing the connector to the vehicle and the specific terminals used vary significantly across manufacturers and models. A quick glance through a connector supplier catalog reveals a vast array of connector housings (the plastic component) and terminals (the metal contacts), highlighting the lack of true standardization beyond the pin configuration.

The Pitfalls of Cheap Aftermarket OBD2 Connectors

The allure of inexpensive OBD2 connectors available online, sometimes for as little as $12, can be strong. While these budget options might seem like a quick fix, they often come with significant drawbacks. One notable issue is the mounting mechanism. These universal connectors rarely fit the original vehicle’s mounting bracket, requiring makeshift solutions like self-tapping screws to attach them under the dashboard. This compromised installation is often flimsy and short-lived.

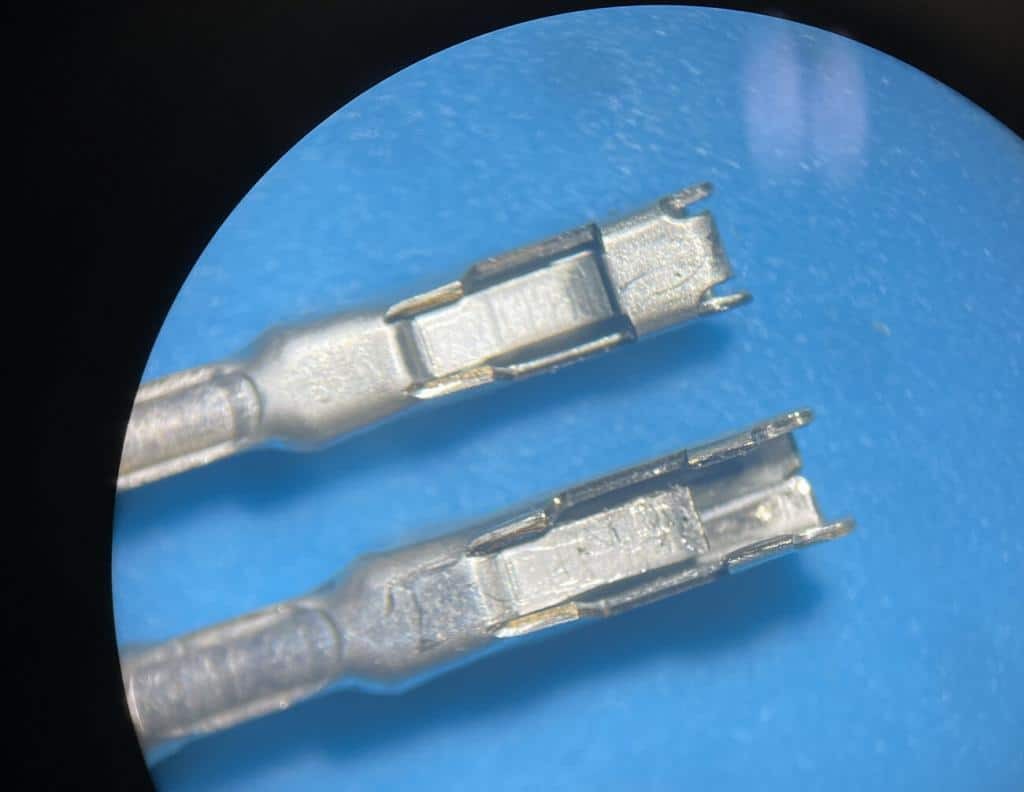

However, the more critical concern lies in the subpar quality of the terminals used in these cheap connectors. Typically made from soft metal with poor spring retention, these terminals may provide an initial connection but are prone to failure over time. While installing such a connector might temporarily “repair” the OBD2 port, the longevity and reliability of the fix are questionable.

Considering the labor involved in replacing an OBD2 connector – which includes terminal installation, dashboard disassembly for wiring access, soldering, and heat shrinking – using substandard parts becomes a false economy. The labor alone can easily exceed $200 at current rates. Investing in quality components is essential to avoid repeat repairs, warranty issues, and customer dissatisfaction.

The OEM Advantage for OBD2 Port Replacement

Opting for Original Equipment Manufacturer (OEM) parts is generally the best approach for OBD2 port replacement, though it can present its own set of challenges. Toyota, for example, while not explicitly listing complete OBD2 connectors in their parts catalogs, does offer the components individually. The key to sourcing these OEM parts lies in navigating the vehicle’s electrical wiring diagrams available through Toyota’s Technical Information System (TIS). By selecting the OBD2 connector in the wiring diagram and clicking the information box, the part number for the plastic connector housing is revealed.

Interestingly, this connector part number information is also accessible in older, pre-digital Toyota service manuals, often found in documents listing connector part numbers by wiring diagram codes within TIS.

However, obtaining the connector housing is only half the solution. The metal terminals are also necessary for a complete repair. A real-world example involves repairing the OBD2 connector on a Gen 3 Prius. Inquiring with a Toyota dealer, providing the connector number and vehicle application, may lead to identifying the correct terminals. Dealer parts departments may need to consult with their service managers or experienced technicians to pinpoint the right terminal part numbers, sometimes even relying on salvaged terminals from their workshop stock when official part numbers are elusive.

OEM OBD2 Repair Terminals: Cost Considerations

Through persistent effort, the correct OEM terminal part number for certain Toyota models, such as the Gen 3 Prius, may be identified as 82998-05010. While this ensures a perfect fit and quality, the cost per terminal and pigtail can be surprisingly high – around $21. While seemingly minor in the context of overall auto repair expenses, this price point is disproportionate to the actual production cost of the terminal. Factors like warehousing, distribution, and markup contribute to the elevated price, making it a less cost-effective option for multiple terminal replacements.

Exploring Connector Experts and Aftermarket Alternatives

Companies like Connector Experts offer a viable alternative by providing reproductions of OEM connectors and terminals. While initially untested, research suggests that their terminal part number TERM86 is a compatible replacement, mirroring the quality of OEM terminals. In direct comparison, Connector Experts’ terminals exhibit similar metal hardness, springiness, and dimensional accuracy to their OEM counterparts, often at a significantly lower price point – potentially ten times cheaper. While these terminals may not include a pigtail wire, the cost savings can be substantial.

Mouser Electronics is another potential source for automotive connectors and terminals, offering a vast inventory. However, navigating their extensive catalog to pinpoint the exact required part can be a complex and time-consuming task.

The Importance of Proper OBD2 Terminal Crimping

Every automotive technician understands the necessity of reliable wire crimping. While standard crimping tools often suffice for older, larger gauge automotive terminals, they typically fall short when working with the smaller, open-barrel terminals used in modern connectors like OBD2 ports. Finding crimping tools capable of producing factory-quality crimps on these delicate terminals is crucial for ensuring robust and lasting electrical connections. Specialized tools, such as those from Engineer (a Japanese manufacturer), are designed specifically for these precision crimping tasks. Despite their unassuming appearance, these tools are engineered to create crimps that are virtually indistinguishable from factory-original crimps, ensuring optimal conductivity and mechanical strength.

Further Reading on Automotive Electrical Repair

For those interested in expanding their knowledge of automotive electrical repairs, these related articles offer valuable insights:

- Custom Battery Cable Fabrication

- Rodent Damage to Prius High Voltage Batteries

- Prius Speedometer (Combination Meter) Repair