When your car starts acting up – maybe that check engine light flickers on, or you’re suddenly visiting the gas station more often – your car’s oxygen sensor (O2 sensor) could be the culprit. This small but mighty component plays a vital role in your engine’s management system. It constantly monitors the oxygen levels in your exhaust, ensuring your engine maintains the optimal air-fuel mixture for peak performance and efficiency. When an O2 sensor malfunctions, it can throw off this delicate balance, leading to a range of issues.

Luckily, diagnosing O2 sensor problems has become much easier thanks to the OBD2 scanner. This tool is indispensable for any car owner or DIY mechanic looking to understand their vehicle’s health.

Before we dive into using an OBD2 scanner for O2 sensor diagnosis, let’s briefly understand how these sensors operate and why they are so crucial.

Understanding the O2 Sensor and OBD2 Scanner Connection

The oxygen sensor, often referred to as the O2 sensor, is positioned in your car’s exhaust system. Its job is to measure the amount of oxygen in the exhaust gases after combustion. This information is then relayed to your car’s Engine Control Unit (ECU), which uses it to fine-tune the air-fuel mixture entering the engine. A precise air-fuel ratio is essential for optimal engine performance, fuel efficiency, and minimizing harmful emissions.

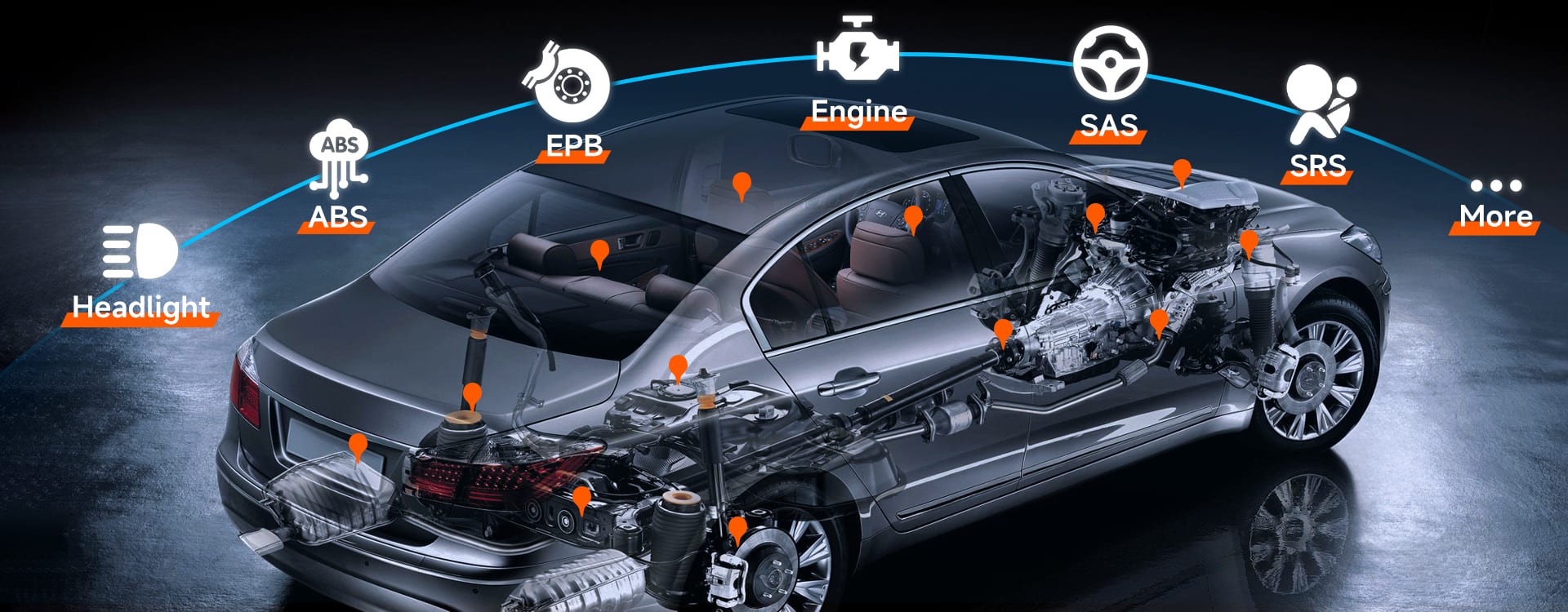

An OBD2 scanner acts as a bridge between you and your car’s computer system. It plugs into the OBD-II port, a standardized diagnostic port found in most vehicles manufactured after 1996. Once connected, the scanner can retrieve a wealth of data, including trouble codes, live sensor readings, and diagnostic test results, empowering you to understand what’s happening under the hood. For diagnosing O2 sensors, an OBD2 scanner is your best friend.

Step-by-Step Guide: Using an OBD2 Scanner to Check Your O2 Sensor

Using an OBD2 scanner to check your O2 sensor is a straightforward process, even for those with limited mechanical experience. Let’s break down the steps:

-

Locate the OBD-II Port: In most cars, the OBD-II port is located under the dashboard on the driver’s side, typically near the steering column. It’s often inconspicuous, but once you know where to look, it’s easy to find.

-

Plug in Your OBD-II Scanner: With the ignition off, plug your OBD2 scanner firmly into the OBD-II port. Ensure it’s securely connected to establish proper communication.

-

Start Your Car and Scanner: Turn the ignition key to the “ON” position (or start the engine, depending on your scanner’s instructions). Power on your OBD2 scanner. Most scanners will automatically connect to your vehicle’s computer.

-

Navigate to O2 Sensor Test or Live Data: Use your scanner’s menu to find the “O2 Sensor Test,” “Oxygen Sensor Test,” or “Live Data” options. The exact wording may vary depending on your scanner model, such as a FOXWELL NT909 or similar device. Selecting “Live Data” will allow you to monitor real-time readings from the O2 sensors.

-

Select O2 Sensor Parameters: Within the Live Data menu, you’ll likely need to select specific parameters to display. Choose parameters related to O2 sensors, such as “O2 Sensor Voltage (Bank 1 Sensor 1),” “O2 Sensor Voltage (Bank 1 Sensor 2),” etc.

Interpreting O2 Sensor Readings

Once you’re viewing live O2 sensor data on your OBD2 scanner, understanding what the readings mean is crucial. A healthy O2 sensor should exhibit certain characteristics:

-

Voltage Fluctuations: A properly functioning O2 sensor will show voltage readings that fluctuate between approximately 0.1 volts and 0.9 volts. These fluctuations indicate that the sensor is actively monitoring oxygen levels and responding to changes in the exhaust stream. Think of it like a heartbeat – consistent variation is a good sign.

-

Quick Response Time: The voltage readings should change relatively quickly in response to engine conditions. A sluggish response time can indicate a slow or degraded sensor. Ideally, the sensor should switch between rich (low voltage) and lean (high voltage) readings multiple times per second under normal operating conditions.

-

Fuel Trim Analysis: Beyond voltage readings, pay attention to Short-Term Fuel Trim (STFT) and Long-Term Fuel Trim (LTFT) values, also available in the Live Data section of your OBD2 scanner. These values represent the adjustments your car’s computer is making to the fuel mixture. If an O2 sensor is providing inaccurate data, the ECU will attempt to compensate, leading to significant fluctuations or deviations in STFT and LTFT values. Large positive or negative fuel trim values can point to an O2 sensor issue or other problems affecting the air-fuel mixture.

Decoding O2 Sensor Trouble Codes with an OBD2 Scanner

An OBD2 scanner is invaluable for retrieving Diagnostic Trouble Codes (DTCs) when your check engine light illuminates. These codes provide specific clues about potential problems, including O2 sensor malfunctions.

Understanding Common O2 Sensor Trouble Codes

When you run a scan, the OBD2 scanner will display any stored DTCs. Codes related to O2 sensors typically start with “P” (for Powertrain) followed by four digits. Here are a couple of common examples:

-

P0130 (O2 Sensor Circuit Malfunction Bank 1 Sensor 1): This code indicates a general problem with the O2 sensor circuit for Bank 1, Sensor 1. “Bank 1” refers to the side of the engine containing cylinder number 1, and “Sensor 1” designates the upstream sensor, located before the catalytic converter. Possible causes include a faulty sensor, wiring issues, or a problem with the sensor’s heater circuit.

-

P0171 (System Too Lean Bank 1): This code indicates that the engine is running lean on Bank 1, meaning there’s too much air and not enough fuel in the air-fuel mixture. While this code doesn’t directly point to an O2 sensor failure, a malfunctioning upstream O2 sensor (Sensor 1) can provide incorrect readings, causing the ECU to lean out the fuel mixture unnecessarily. However, other issues like vacuum leaks, fuel delivery problems, or intake manifold leaks can also trigger this code.

Steps to Diagnose Trouble Codes

Once you’ve retrieved trouble codes with your OBD2 scanner, follow these steps for effective diagnosis:

-

Read Code Descriptions: Your OBD2 scanner may provide brief descriptions of the codes. If not, you can easily search online for “OBD2 code Pxxxx description” to understand the meaning of each code.

-

Inspect Wiring and Connections (for P0130 and similar sensor circuit codes): For codes like P0130, visually inspect the wiring and connectors associated with the indicated O2 sensor. Look for frayed wires, loose connections, or corrosion. Sometimes, simply cleaning and reconnecting the sensor connector can resolve the issue.

-

Test the O2 Sensor Heater Circuit (if applicable): Many O2 sensors are equipped with a heater element to help them reach operating temperature quickly. If you have a code related to the heater circuit (e.g., P0135), you can use a multimeter to check the heater circuit for continuity. Lack of continuity suggests a faulty heater, requiring sensor replacement.

-

Verify with Live Data: After addressing potential wiring or heater issues, use your OBD2 scanner to monitor live O2 sensor data again. Observe if the voltage readings and response times have improved. If the sensor still exhibits erratic behavior or no voltage fluctuations, sensor replacement may be necessary.

Avoiding Common Misdiagnoses

It’s crucial to remember that O2 sensor codes don’t always definitively mean the sensor itself is bad. Here are common misdiagnoses to avoid when using an OBD2 scanner for O2 sensor issues:

-

Don’t Immediately Replace the Sensor: Codes like P0171 (lean condition) can be triggered by various factors unrelated to the O2 sensor. Before replacing the sensor, investigate other potential causes such as vacuum leaks, faulty fuel injectors, a clogged fuel filter, or even intake air leaks. A systematic approach to diagnosis is key.

-

Check for Exhaust Leaks: Exhaust leaks near the O2 sensor can introduce extra oxygen into the exhaust stream, causing the sensor to read lean and potentially trigger false codes. Inspect the exhaust system for any signs of leaks, such as hissing noises or visible damage, especially around the O2 sensor.

-

Don’t Overlook Basic Maintenance: Sometimes, seemingly complex sensor-related issues can stem from simple neglect. Ensure your air filter is clean, your fuel cap is properly tightened, and you’re using good quality fuel. These basic factors can influence the air-fuel mixture and potentially trigger codes that might mistakenly point to an O2 sensor problem.

By following a thorough diagnostic process and using your OBD2 scanner effectively, you can accurately determine if your O2 sensor is truly at fault or if another underlying issue is causing the problem. This approach saves time, money, and unnecessary parts replacements.

Key Indicators of a Healthy O2 Sensor

To summarize, here’s what to look for when assessing your O2 sensor’s health using an OBD2 scanner:

- Consistent Voltage Fluctuations: Readings should oscillate between 0.1V and 0.9V.

- Rapid Response Time: Voltage changes should be quick and responsive to engine changes.

- Stable Fuel Trim Values: STFT and LTFT should be within a reasonable range, indicating proper air-fuel mixture control.

Symptoms of a Failing O2 Sensor

Even without an OBD2 scanner, you might notice symptoms indicating a potential O2 sensor problem:

- Reduced Fuel Economy: A faulty O2 sensor can lead to an improperly rich fuel mixture, wasting fuel.

- Rough Idling: An incorrect air-fuel ratio can cause engine misfires and a rough idle.

- Check Engine Light: This is often the first sign of an O2 sensor issue, triggering related trouble codes.

- Failed Emissions Test: Malfunctioning O2 sensors can result in increased emissions, leading to failing an emissions test.

- Engine Hesitation or Misfires: Poor air-fuel control can cause hesitation during acceleration or engine misfires.

Conclusion

Using an OBD2 scanner to diagnose O2 sensor issues is an empowering way to take control of your car’s maintenance. With a bit of knowledge and the right tool, you can confidently assess your O2 sensor’s health, interpret trouble codes, and make informed decisions about repairs. Regular checks with an OBD2 scanner can help you catch potential problems early, keeping your engine running smoothly, efficiently, and saving you from costly repairs down the road.

FAQs

How to read O2 sensor data on a scan tool?

Connect your OBD2 scanner to the OBD-II port, navigate to “Live Data” or “O2 Sensor Test,” and select the relevant O2 sensor parameters (e.g., voltage). Monitor the voltage readings, looking for fluctuations between 0.1V and 0.9V for a healthy sensor.

What are signs of a bad O2 sensor?

Signs of a bad O2 sensor include decreased fuel economy, rough idle, check engine light illumination, failed emissions tests, engine misfires, and hesitation during acceleration.

How do you read an O2 sensor with a multimeter?

To read an O2 sensor with a multimeter, set the multimeter to DC voltage. With the engine running and warmed up, connect the multimeter probes to the sensor’s signal wire and ground wire. A functioning sensor should show fluctuating voltage between 0.1V and 0.9V.