In today’s vehicles, Engine Control Units (ECUs) are sophisticated computers managing a multitude of engine functions. Key to their operation are sensors like the camshaft position sensor (CMP) and crankshaft position sensor (CKP). These sensors provide crucial data for precise fuel injection and ignition timing. When these sensors, or related engine components, are replaced or disturbed, a “relearn” procedure becomes essential. This guide will explore the importance of camshaft and crankshaft relearn using an OBD2 scanner, ensuring your engine runs smoothly and efficiently.

The Vital Role of Camshaft and Crankshaft Position Sensors

The crankshaft position sensor (CKP) and camshaft position sensor (CMP) are indispensable for modern engine management. The CKP sensor monitors the crankshaft’s position and rotational speed, providing the ECU with the primary timing reference. Simultaneously, the CMP sensor tracks the camshaft’s position, helping the ECU identify which cylinder is firing and optimize valve timing in engines with variable valve timing systems. Accurate readings from these sensors are paramount for:

- Precise Ignition Timing: Ensuring spark plugs fire at the optimal moment for efficient combustion.

- Optimized Fuel Injection: Delivering the correct amount of fuel at the right time, enhancing fuel economy and reducing emissions.

- Smooth Engine Performance: Preventing misfires, rough idling, and engine stalling.

- Diagnostic Accuracy: Aiding the ECU in identifying and reporting engine issues accurately.

When is a Camshaft or Crankshaft Relearn Necessary?

Performing a camshaft or crankshaft relearn procedure is crucial in various situations to synchronize the ECU with the sensor data. Here are key scenarios where relearn becomes necessary:

- Sensor Replacement: Whenever a CKP or CMP sensor is replaced, even with an OEM part, a relearn is vital. Manufacturing variations can lead to slight differences that the ECU needs to learn.

- ECU Replacement or Reset: Replacing or resetting the ECU to factory settings erases learned sensor data, necessitating a relearn.

- Engine Work Affecting Timing: Repairs involving timing chains, timing belts, crankshaft pulleys, or camshaft adjustments require a relearn to ensure timing accuracy.

- Flywheel or Harmonic Balancer Replacement: These components are directly related to crankshaft position sensing. Replacement impacts sensor readings and necessitates a relearn.

- Software Updates: ECU software updates can sometimes require sensor relearns to align new software parameters with existing sensor calibrations.

- Driveability Issues: Symptoms like engine hesitation, stalling, rough idle, or misfires, especially after sensor or engine work, can indicate a need for relearn.

Step-by-Step Guide to Performing a Crankshaft Relearn with an OBD2 Scanner

This section outlines the general steps for performing a crankshaft relearn. Specific procedures may vary slightly depending on your OBD2 scanner and vehicle make and model. Always consult your scanner’s manual and vehicle service information for precise instructions. For this example, we’ll reference the CGSULIT SC530, an OBD2 scanner equipped with camshaft and crankshaft relearn capabilities.

Step 1: Preliminary Checks and Preparations

- Battery Voltage Check: Ensure your vehicle’s battery is in good condition and fully charged (ideally above 12.6V). Low voltage can interrupt the relearn process.

- Engine Temperature: The engine should be at normal operating temperature for an accurate relearn.

- Scanner Compatibility: Verify that your OBD2 scanner supports crankshaft relearn for your specific vehicle make, model, and year. Check the scanner’s vehicle coverage list or manufacturer’s website.

- Software Updates: Ensure your OBD2 scanner has the latest software updates installed. Updates often include enhanced vehicle coverage and improved relearn procedures.

Step 2: Connecting Your OBD2 Scanner

- Locate the OBD2 Port: The OBD2 port is typically situated under the dashboard on the driver’s side. Refer to your vehicle’s owner’s manual if you are unsure of its location.

- Ignition ON, Engine OFF: Turn the vehicle’s ignition to the “ON” position (sometimes called “Key On, Engine Off” or KOEO). Do not start the engine.

- Connect the Scanner: Plug your OBD2 scanner securely into the OBD2 port.

- Power On Scanner and Vehicle Identification: Turn on your OBD2 scanner and allow it to power up. Follow the scanner’s prompts to identify your vehicle. This usually involves selecting the make, model, and year from menus on the scanner.

Step 3: Accessing the Crankshaft Relearn Function

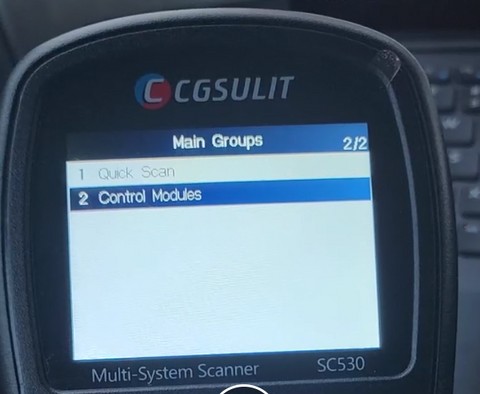

- Navigate to Diagnostics Menu: On your OBD2 scanner, navigate to the “Diagnostics” or “Service Functions” menu. The exact menu names can vary between scanners.

- Enter Control Module Diagnostics: Select “Control Module Diagnostics” or a similar option that allows you to access specific vehicle systems.

- Select Engine Control Module (ECM) or Powertrain Control Module (PCM): Choose the engine control module. This module is often labeled as “ECM,” “PCM,” or “Engine.”

- Find “Special Functions” or “Service Procedures”: Within the ECM/PCM menu, look for options like “Special Functions,” “Service Procedures,” “Adaptations,” or “Actuations.”

- Locate “Crankshaft Position (CKP) Variation Learn” or similar function: Scroll through the list of special functions until you find the “Crankshaft Position (CKP) Variation Learn,” “Crankshaft Relearn,” or a similarly named function. It might also be listed as “CKP System Variation Learn.”

Step 4: Executing the Relearn Procedure

- Follow On-Screen Instructions: Once you’ve selected the crankshaft relearn function, carefully read and follow the on-screen instructions provided by your OBD2 scanner. These instructions are critical and may include steps like:

- Ensuring the vehicle is in Park or Neutral with the parking brake engaged.

- Starting the engine (in some cases, the procedure might be engine-off).

- Maintaining a specific engine speed or throttle position for a duration.

- Waiting for the scanner to indicate completion.

- Initiate Relearn: Typically, you will need to press a button on the scanner to initiate the relearn process.

- Monitor Progress: Observe the scanner’s screen for progress updates and any prompts.

- Completion Confirmation: The scanner should display a message indicating whether the relearn procedure was successful or not. Note any error messages if the relearn fails.

Step 5: Post-Relearn Verification and Testing

- Clear Diagnostic Trouble Codes (DTCs): After a successful relearn, use your OBD2 scanner to clear any DTCs that may have been set during the process.

- Verify Relearn Completion: Some scanners allow you to verify if the relearn procedure was successfully stored in the ECU. Check your scanner’s capabilities.

- Road Test: Perform a road test to assess engine performance. Pay attention to idle quality, acceleration, and overall smoothness.

- Scan for DTCs Again: After the road test, rescan the vehicle for any new DTCs to ensure no issues persist.

Troubleshooting Common Relearn Issues

- Relearn Failure: If the relearn procedure fails, check the following:

- Battery Voltage: Ensure stable and sufficient battery voltage.

- Engine Temperature: Verify the engine is at operating temperature.

- Scanner Compatibility: Double-check your scanner’s compatibility with your vehicle.

- Sensor and Wiring Issues: Inspect the CKP and CMP sensors and their wiring for damage or poor connections.

- Underlying Mechanical Problems: In rare cases, mechanical issues like timing chain stretch or camshaft/crankshaft misalignment can prevent successful relearn.

- Persistent DTCs: If DTCs related to CKP or CMP sensors reappear after relearn, consider:

- Sensor Fault: The new sensor itself might be faulty (though rare).

- Wiring Problems: Thoroughly inspect sensor wiring and connectors.

- Timing Issues: Investigate potential timing chain or belt problems.

- Scanner Software Issues: Ensure your scanner’s software is up to date. Contact the scanner manufacturer’s support if you suspect a software glitch.

Camshaft Relearn Procedures

While this guide primarily focuses on crankshaft relearn, the process for camshaft relearn is often very similar. OBD2 scanners with relearn capabilities frequently offer both crankshaft and camshaft relearn functions within the “Special Functions” menu of the ECM/PCM. The steps for accessing and executing camshaft relearn are generally analogous to the crankshaft relearn process outlined above. Always refer to your scanner’s manual and vehicle-specific service information for detailed instructions on camshaft relearn if required.

Conclusion

Performing a camshaft or crankshaft relearn using an OBD2 scanner is a vital step in modern vehicle maintenance and repair. By understanding the importance of these procedures and following a systematic approach, you can ensure optimal engine performance, fuel efficiency, and diagnostic accuracy. While OBD2 scanners empower DIY enthusiasts and professional technicians alike, remember that complex diagnostic issues may require the expertise of a qualified mechanic. Always prioritize safety and consult professional help when needed.

FAQs

-

Q: Can I use any OBD2 scanner for crankshaft and camshaft relearn?

A: No. Standard basic OBD2 scanners typically only read and clear diagnostic codes. You need a professional-grade OBD2 scanner with “special functions” or “bi-directional control” capabilities to perform relearn procedures. Verify scanner specifications before purchase. -

Q: What happens if I don’t perform a crankshaft relearn after sensor replacement?

A: Failure to perform a relearn can lead to various engine performance issues, including rough idling, misfires, hesitation, reduced power, and potentially engine stalling. It can also trigger inaccurate diagnostic trouble codes. -

Q: How do I know if my crankshaft relearn was successful?

A: Your OBD2 scanner should display a “successful” or “completed” message after the procedure. Additionally, a smooth-running engine without DTCs related to CKP or CMP sensors after a road test indicates a successful relearn. -

Q: Is camshaft relearn always necessary when replacing a camshaft sensor?

A: Yes, in most modern vehicles, a camshaft relearn is recommended or required after camshaft position sensor replacement to ensure accurate synchronization between the sensor and the ECU. Consult your vehicle’s service information for specific requirements.