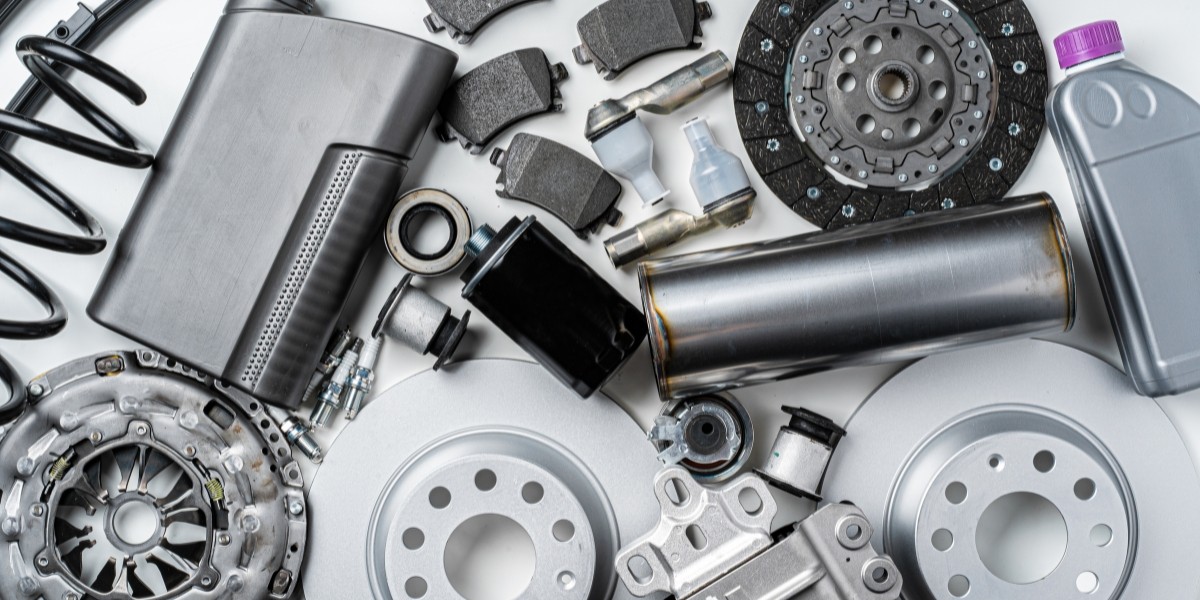

Excessive inventory of car parts can significantly hinder the financial health of automotive dealerships. Overstock Car Parts not only occupy valuable storage space but also tie up crucial capital, leading to potential financial losses and reduced profitability. Fortunately, dealerships can implement several effective strategies to manage and mitigate the challenges associated with overstock car parts, turning a potential liability into an opportunity for improved efficiency and revenue.

Automotive parts inventory management for dealerships

Automotive parts inventory management for dealerships

1. Diagnose the Root Causes of Your Overstock Car Parts

The first step towards resolving the issue of overstock car parts is to thoroughly understand its origins within your dealership. Begin by meticulously identifying the specific parts that consistently contribute to your surplus inventory. Compile a detailed list of items that are frequently overstocked, those often sold at discounted prices to move them, and parts that are particularly susceptible to becoming obsolete due to model year changes or technological advancements.

For each Stock Keeping Unit (SKU) identified as problematic, conduct a comprehensive analysis. Evaluate key metrics such as the part’s turnover rate – how quickly it sells – delivery lead times from suppliers, profit margins to understand its contribution to revenue, and the associated storage costs. This in-depth analysis will allow you to weigh the financial burden of holding the inventory against the potential risk of obsolescence, clearly highlighting the specific areas within your parts department that require immediate attention and strategic adjustments.

2. Implement Quick-Win Solutions for Immediate Relief from Overstock

When dealing with overstock car parts that have limited future sales prospects, decisive action is necessary. While complete disposal might seem like the only option, explore various avenues to recoup value from this surplus inventory before resorting to discarding it outright. Consider selling these overstock parts to your customer base at discounted rates, offering them as package deals, or promoting them to local auto repair shops and service providers who might utilize them.

Disassembly of certain overstock assemblies can also yield reusable components or raw materials. Engage with neighboring dealerships to explore potential exchanges or sales of parts that may be overstocked in your inventory but needed elsewhere. Investigate manufacturer return programs, which can provide a channel for returning slow-moving or obsolete parts for credit. Furthermore, consider donating suitable overstock parts to vocational schools or training programs for educational purposes, potentially benefiting from tax deductions while supporting automotive education.

3. Tackle Operational Inefficiencies Contributing to Overstock Car Parts

Effective management of overstock car parts goes beyond reactive measures. It requires a proactive approach to address the underlying operational inefficiencies within your inventory management system that contribute to the problem in the first place. Common culprits often include overly optimistic sales forecasts that lead to inflated orders, communication breakdowns between service, sales, and parts departments resulting in mismatched stock levels, and rapid technological shifts in the automotive industry that quickly render certain parts obsolete.

Vendor-related challenges, such as minimum order quantities or inflexible return policies, can also force dealerships to overstock. Inaccurate inventory record-keeping, whether due to manual errors or outdated systems, further exacerbates the issue. Finally, inadequate planning for seasonal demand fluctuations or model year transitions can lead to predictable cycles of overstock. Identifying and systematically rectifying these root operational issues is paramount for achieving long-term efficiency and preventing future accumulation of overstock car parts.

4. Develop Long-Term Strategies for Sustainable Inventory Control

While addressing immediate overstock is crucial, establishing robust long-term strategies for inventory control is essential for sustained success. Recognize that errors in inventory management are almost inevitable, particularly during peak sales periods or when dealing with complex parts catalogs. To minimize these errors and proactively manage both overstock and obsolescence, prioritize improvements in several key areas.

Focus on refining your standard operating procedures for inventory management, ensuring clarity and consistency across all departments. Evaluate your organizational structure to ensure accountability and efficient information flow within the parts department. Implement more frequent and rigorous physical inventory counts to maintain accurate stock records and identify discrepancies promptly. Invest in enhancing the accuracy of your demand forecasting methods, utilizing historical data and market trends to predict future parts needs more effectively. Finally, refine your parts ordering processes, basing order quantities on actual turnover rates, realistic delivery times, and optimized stock levels rather than relying on guesswork or outdated assumptions.

5. Harness Data Analytics for Smarter Overstock Management

In today’s data-driven environment, leveraging data analytics tools is no longer optional but a necessity for effective overstock car parts management. Implement or optimize your use of data analytics platforms to gain deeper, actionable insights into your inventory trends, customer purchasing preferences, and evolving market demand. By meticulously analyzing historical sales data, you can identify patterns, predict future demand with greater accuracy, and optimize your inventory levels accordingly.

Data analytics can reveal slow-moving parts, seasonal demand fluctuations, and the impact of promotions or marketing campaigns on parts sales. This intelligence empowers you to make data-backed decisions regarding ordering quantities, promotional strategies for overstock items, and overall inventory management, significantly minimizing the risk of accumulating excess and obsolete car parts.

6. Foster a Culture of Continuous Improvement in Parts Management

Effective management of overstock car parts is not a one-time fix but an ongoing process that requires a commitment to continuous improvement. Establish a dealership-wide culture that values and encourages feedback from all staff members involved in inventory handling, from parts counter personnel to warehouse staff and service technicians. Regularly review and refine your inventory management procedures based on key performance indicators, staff feedback, and evolving market dynamics.

Implement regular training programs to keep your parts department team updated on best practices in inventory management, new technologies, and efficient processes. By continuously seeking opportunities to enhance efficiency, adapt to changing market conditions, and learn from both successes and mistakes, your dealership can proactively reduce the risk of surplus auto parts inventory and achieve sustained improvements in overall operational effectiveness and profitability.

Remember, identifying the specific root causes of your overstock challenges is absolutely critical for implementing the most effective and tailored solutions. For dealerships seeking expert assistance in diagnosing and resolving complex inventory issues, providing specialized training for parts department teams, or requiring professional support in performing accurate inventory counts and valuations, our team of experienced automotive inventory professionals is readily available to provide support and guidance.

[