When your vehicle starts exhibiting unusual behavior, such as the check engine light illuminating or a noticeable decrease in fuel efficiency, it’s often a sign that something is wrong with your oxygen (O2) sensor. This critical component plays a vital role in your car’s engine management system by monitoring the amount of oxygen in the exhaust gases. This information is crucial for regulating the air-fuel mixture and ensuring optimal engine performance. If the O2 sensor malfunctions, it can lead to various engine problems and increased emissions.

To effectively diagnose issues related to your O2 sensor, an OBD2 scanner is an indispensable tool. This guide will walk you through the process of Oxygen Sensor Testing Using Obd2, helping you understand how to use this technology to identify and address potential sensor problems.

Connecting and Diagnosing an O2 Sensor with an OBD-II Scanner

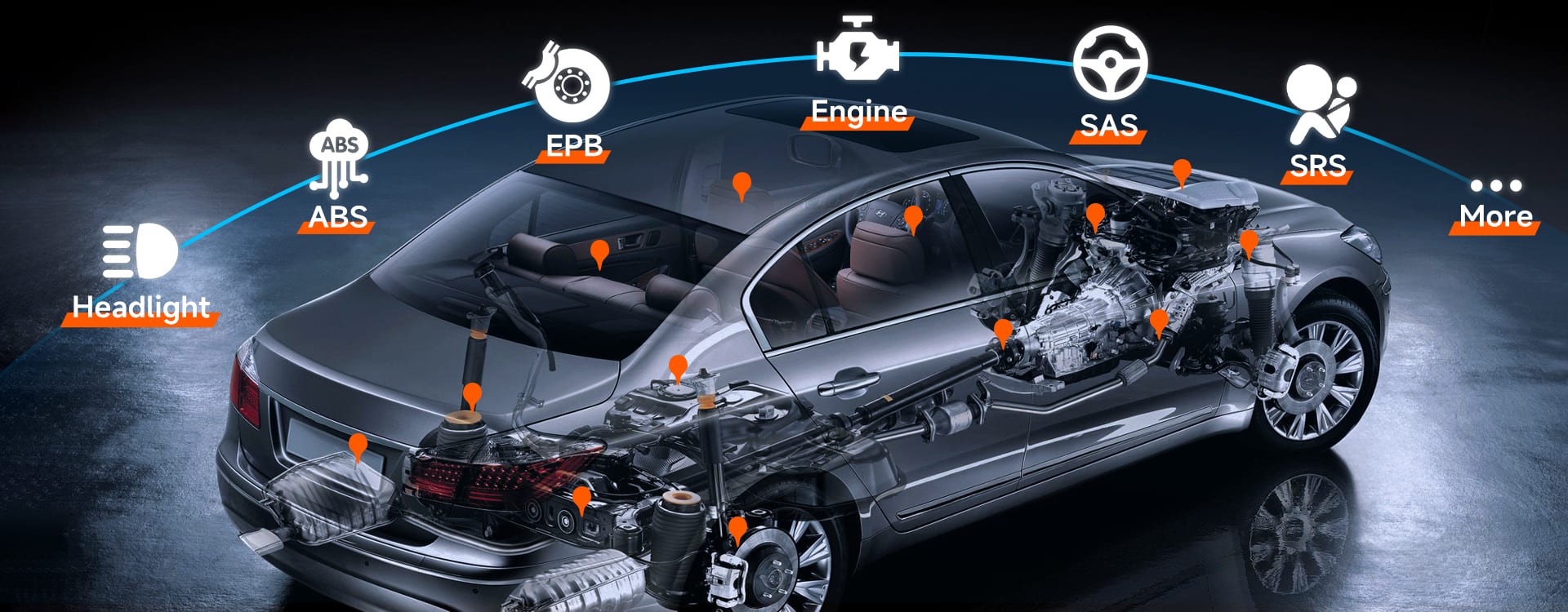

Alt text: Foxwell NT530 OBD2 scanner displaying full system diagnostic capabilities for comprehensive vehicle health checks.

Before diving into the specifics of oxygen sensor testing using OBD2, it’s important to understand the basic procedure for connecting and using an OBD-II scanner. Whether you’re using a sophisticated FOXWELL NT909 scanner or another model, the process is generally user-friendly, even for those with limited mechanical experience.

1. Locate the OBD-II Port: In all vehicles manufactured since 1996, the OBD-II port is a standard feature. You can typically find it located under the dashboard on the driver’s side, often near the steering column. Finding this port is the first step to accessing your vehicle’s diagnostic data.

2. Plug in Your OBD-II Scanner: Once you’ve located the OBD-II port, carefully plug in your scanner. Ensure a firm connection to establish proper communication between the scanner and your car’s computer system.

3. Start Your Car and Scanner: Turn on your vehicle’s ignition and then power on your OBD-II scanner. The scanner will usually guide you through a menu. Look for options like “Diagnostics,” “Live Data,” or specifically an “O2 Sensor Test” to begin the diagnostic process.

4. Navigating Your Scanner: Modern OBD2 scanners, such as the FOXWELL NT909, are designed with intuitive interfaces. This makes accessing live data from the O2 sensors straightforward. Typically, you can navigate through menus and select options using buttons or a touchscreen, following the on-screen prompts to reach the O2 sensor data.

Reading and Interpreting O2 Sensor Data for Effective Testing

This is where the real diagnostic work begins. Your O2 sensor generates a voltage signal that fluctuates based on the oxygen levels in the exhaust. Think of it as a vital sign of your engine’s health, similar to a heartbeat.

A properly functioning O2 sensor should exhibit a voltage range between 0.1V and 0.9V. The voltage should also fluctuate dynamically, indicating that the sensor is actively monitoring and responding to changes in the exhaust gases. A steady, unchanging voltage at either the high or low end of this range is a red flag, suggesting a potential sensor malfunction.

Pay close attention to the sensor’s response time. A healthy O2 sensor should switch rapidly between high and low voltage readings, ideally multiple times per second. A sluggish response or slow switching indicates that the sensor might be degrading or failing.

However, O2 sensor data alone isn’t the complete picture. To get a comprehensive understanding, you should also monitor Short-Term Fuel Trim (STFT) and Long-Term Fuel Trim (LTFT) values. These readings show how your car’s computer is adjusting the fuel mixture in response to the O2 sensor’s input. If the O2 sensor is providing inaccurate readings, these fuel trim values will often fluctuate erratically as the engine control unit (ECU) struggles to maintain the correct air-fuel ratio. It’s like the engine trying to balance on a seesaw that’s constantly being tilted.

Understanding O2 Sensor-Related Trouble Codes for Accurate Diagnosis

When performing oxygen sensor testing using OBD2, understanding Diagnostic Trouble Codes (DTCs) is crucial. These codes, retrieved by your OBD-II scanner, provide specific information about potential issues within your vehicle’s systems, including the O2 sensors. They are essential clues in determining if an O2 sensor is indeed the source of the problem.

Deciphering Common Trouble Codes

After connecting your OBD-II scanner and running a diagnostic scan, the device will retrieve DTCs from your vehicle’s computer. These codes typically begin with the letter “P” (for powertrain) followed by four numerical digits. Codes like P0130 or P0171 are commonly associated with oxygen sensor problems.

-

P0130 (O2 Sensor Circuit Malfunction (Bank 1, Sensor 1)): This code indicates a malfunction in the circuit of O2 Sensor 1 in Bank 1. “Bank 1” refers to the side of the engine that contains cylinder number 1, and “Sensor 1” denotes the upstream O2 sensor, located before the catalytic converter. This code often points to issues with the sensor itself, its wiring, or the heater circuit.

-

P0171 (System Too Lean (Bank 1)): This code signifies that the engine’s air-fuel mixture in Bank 1 is running too lean, meaning there’s too much air and not enough fuel. While this code can be triggered by a faulty O2 sensor providing incorrect data to the ECU, leading to improper air-fuel adjustments, it can also be caused by other problems such as vacuum leaks or malfunctioning fuel injectors.

Steps to Effectively Diagnose Trouble Codes

Once you have retrieved trouble codes using your scanner, the first step is to consult the code descriptions. Many advanced scanners, such as the FOXWELL NT909, offer built-in code explanations. If your scanner doesn’t provide descriptions, you can easily find this information online or in a vehicle repair manual.

-

Investigating Code P0130: When you encounter code P0130, your initial step should be a thorough visual inspection of the wiring and connectors associated with the affected O2 sensor. Look for any signs of damage, such as frayed wires, corrosion, or loose connections. Sometimes, simply re-securing a loose connector can resolve the issue.

-

Testing the O2 Sensor Heater Circuit: Many O2 sensors are equipped with an internal heater to help them reach operating temperature quickly. If you encounter a trouble code specifically related to the heater circuit (e.g., P0135), use a multimeter to test the heater circuit for continuity. A lack of continuity usually indicates a faulty heater, necessitating sensor replacement.

-

Verifying with Live Data: After identifying a trouble code, it’s crucial to use your OBD2 scanner to monitor live O2 sensor data in real-time. This allows you to confirm whether the sensor is indeed malfunctioning. Abnormal voltage readings, slow response times, or a lack of fluctuation can further indicate a faulty sensor.

Common Diagnostic Pitfalls to Avoid

It’s vital to remember that O2 sensor-related codes don’t always directly translate to a faulty sensor. Here are common misdiagnoses to be aware of:

-

Don’t Overlook Other Potential Causes: Codes like P0171, while often associated with O2 sensors, can also arise from vacuum leaks, clogged fuel injectors, or restrictions in the air intake system. Before automatically replacing the O2 sensor, conduct a comprehensive inspection to rule out these other possibilities.

-

Check for Exhaust Leaks: An exhaust leak near an O2 sensor can cause it to read incorrectly, generating false trouble codes. Listen for hissing sounds or visually inspect the exhaust system for damage, especially around the sensor location.

-

Don’t Skip Basic Checks: Sometimes, the solution is simpler than you think. Before proceeding with complex diagnostics, ensure that your air filter is clean, the fuel cap is properly tightened, and the fuel quality is good. These basic factors can sometimes trigger codes that appear sensor-related but are actually due to these simple issues.

By diligently following these diagnostic steps, you can effectively determine if your O2 sensor is genuinely at fault or if another underlying issue is causing the problem. This methodical approach will save you time and money by preventing unnecessary sensor replacements.

Key Indicators of a Properly Functioning O2 Sensor

How can you assess if your O2 sensor is performing as it should? Here are the key indicators of an effective O2 sensor:

-

Consistent Voltage Fluctuations: A functioning sensor should show a continuous fluctuation in voltage between 0.1V and 0.9V. A steady voltage reading at either extreme suggests a problem.

-

Rapid Response Time: A sensor in good condition should quickly switch between high and low voltage states, reflecting its ability to promptly detect changes in exhaust oxygen levels.

-

Stable Fuel Trim Values: If the Short-Term Fuel Trim (STFT) and Long-Term Fuel Trim (LTFT) values are relatively stable and within normal ranges, it’s a good indication that the O2 sensor is providing accurate data and the engine management system is functioning correctly.

Alt text: Foxwell NT710 car scanner showcasing full systems diagnostic capabilities for in-depth vehicle analysis.

Common O2 Sensor Failures and Associated Symptoms

O2 sensors can fail in various ways, impacting their performance. Contamination from oil or coolant can interfere with their readings, leading to inaccurate data. Over time, sensors can degrade due to age and exposure to exhaust gases, resulting in slower response times. In some cases, the heater circuit within the sensor can fail, leading to increased emissions and reduced fuel economy.

Symptoms of a failing O2 sensor can include:

- Decreased fuel economy

- Illuminated check engine light

- Rough idling or engine misfires

- Failed emissions test

- Hesitation or lack of power during acceleration

Conclusion: Empowering You with OBD2 Oxygen Sensor Testing

Using an OBD-II scanner for oxygen sensor testing is a powerful and efficient method for diagnosing potential engine issues early on. With a basic understanding of OBD2 scanners, O2 sensor function, and trouble code interpretation, you can proactively maintain your vehicle’s engine health and prevent more significant problems. Regularly checking your O2 sensor with an OBD2 scanner can save you money on fuel, reduce emissions, and avoid costly repairs at a mechanic. By taking a proactive approach to vehicle maintenance, you ensure your car remains in optimal condition, providing reliable and efficient performance.

FAQs About Oxygen Sensor Testing with OBD2

How do I read O2 sensor data on a scan tool?

To access O2 sensor data on a scan tool, connect the scanner to your vehicle’s OBD-II port. Navigate to the “Live Data” or “O2 Sensor Test” section in the scanner’s menu. Select the O2 sensor parameters you want to monitor, such as voltage readings. A healthy sensor will typically display fluctuating voltage between 0.1V and 0.9V.

What are the telltale signs of a failing O2 sensor?

Key signs of a bad O2 sensor include reduced fuel economy, a rough engine idle, the check engine light turning on, and failing emissions tests. You might also experience engine misfires or hesitation when accelerating.

Can I test an O2 sensor with just a multimeter?

Yes, you can test an O2 sensor using a multimeter, although it’s less comprehensive than using an OBD2 scanner for live data. Set your multimeter to DC voltage. Connect the probes to the sensor’s signal wire and ground. With the engine running, a functioning sensor should show a fluctuating voltage between 0.1V and 0.9V. However, this method doesn’t provide the detailed diagnostic information available through an OBD2 scanner, such as trouble codes and fuel trim data.