Wheels are more than just aesthetic features on your car; they are crucial components that directly impact your vehicle’s performance, handling, and safety. Upgrading to aftermarket wheels can dramatically enhance your car’s appearance, but understanding the terminology and components of a wheel is essential before making any decisions.

Navigating the world of car wheels can be confusing. Terms like “wheel” and “rim” are often used interchangeably, and deciphering wheel specifications can feel like learning a new language. This comprehensive guide will break down the anatomy of a car wheel, explaining the names and functions of each part. Whether you’re a seasoned car enthusiast or a new driver, this knowledge will empower you when you’re considering wheel maintenance, repairs, or upgrades. We’ll delve into car wheel parts, explore how wheels are constructed, discuss the significance of wheel size and offset, and clarify the benefits of upsizing your wheels.

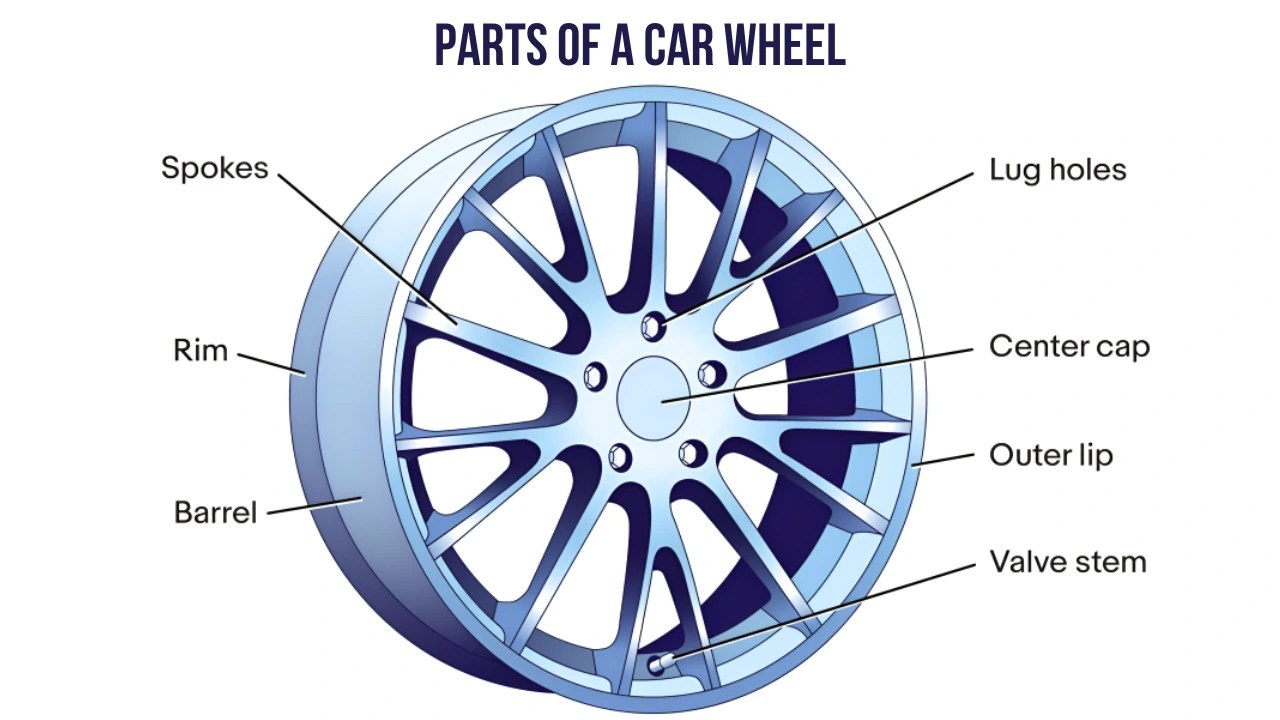

Car Wheel Parts Diagram with Names

Parts Of A Car Wheel Diagram

Parts Of A Car Wheel Diagram

Key Parts of a Car Wheel:

- Wheel Rim

- Tire

- Valve Stem

- Hubcap/Wheel Cover

- Center Cap

- Lug Nuts

- Wheel Studs

- Wheel Spacers

- Wheel Bearings

- Wheel Seal

- Wheel Bolts

- Wheel Locks

- TPMS Sensor

- Rim Flange

- Bead

- Wheel Balancing Weights

- Wheel Valve Cap

- Dust Cap

Exploring the Detailed Parts in a Car Wheel

A car wheel assembly is a complex system composed of several key parts working in harmony. While often simplified into three main components – the tire, the rim, and the hub – a deeper dive reveals a more intricate structure. Let’s examine each of these parts in detail to fully understand their function and importance.

#1. The Wheel Rim (or Disc): The Foundation

The rim, sometimes referred to as the wheel disc, serves as the foundational structure of the wheel. It’s the metallic base, typically constructed from steel or aluminum alloy, upon which all other wheel components are mounted. Imagine it as the skeleton of the wheel, providing the shape and structural integrity necessary to support the tire and withstand the stresses of driving.

For modern tubeless tires, the rim is engineered to create an airtight seal, crucial for maintaining tire pressure. The strength of the rim is paramount as it bears the entire load of the vehicle. Rim dimensions, including width and diameter, are dictated by the vehicle’s specifications to ensure proper tire fitment and handling characteristics. Beyond functionality, car wheel rims are available in a vast array of colors and styles, allowing for customization and aesthetic enhancement.

#2. The Hub: The Connection Point

The hub is the central part of the wheel, acting as the crucial link between the wheel and the vehicle. It’s the component that attaches to the car’s axle and houses vital braking and steering components like brake pads, calipers, and rotors. The hub’s robust design ensures the wheel is securely fastened to the vehicle, enabling movement and controlled stopping.

Often referred to as the wheel hub assembly or wheel bearing hub, this pre-assembled unit contains precision bearings, seals, and sometimes sensors for systems like ABS (Anti-lock Braking System). A properly functioning wheel hub assembly is essential for safe steering and handling. It’s positioned between the drive axle and the brake system (either drum brakes or disc brakes) on each wheel. The wheel itself is bolted to the wheel hub assembly, while the hub assembly is mounted to the steering knuckle.

A failing wheel hub assembly can manifest in several warning signs:

- Unusual Noises: Growling, humming, squeaking, chirping, or squealing sounds emanating from the tires, particularly noticeable at speeds between 30-45 mph.

- Steering Wheel Vibration: Shaking or wobbling of the steering wheel while driving, indicating instability in the wheel assembly.

- ABS Warning Light: Illumination of the ABS warning light on the dashboard, suggesting a potential issue with the hub sensor or signal.

#3. The Tire: The Contact with the Road

Tires are undeniably among the most critical Parts In A Car Wheel system. Without tires, the rim and other wheel components would be largely ineffective. Tires are the vehicle’s only point of contact with the road surface, playing a vital role in traction, handling, and ride comfort.

The primary function of car tires is to provide grip and absorb shocks from road irregularities, working in conjunction with the vehicle’s suspension and shock absorbers. Tires also act as a protective layer, preventing the rims from directly contacting the road.

The tire tread, the outermost layer with a patterned design, is engineered to optimize grip in various driving conditions. Regularly checking tire tread depth is crucial for safety, and tools like a coin can be used for a quick assessment. Car tires are primarily made of rubber, but their composition is complex, incorporating materials like carbon black, textile fibers, and mineral components to achieve specific performance characteristics.

#4. Spokes: Structural Support and Style

Spokes are the connecting structures between the central hub and the outer rim of the wheel. They are fundamental to the wheel’s structural integrity, distributing load and absorbing impacts. Together with the hub, spokes form the visible face of the wheel, contributing significantly to its overall design.

Custom wheels offer a wide variety of spoke styles, playing a major role in visual appeal. Spokes vary in number, width, shape, and pattern, allowing for diverse aesthetic expressions. While some heavy-duty wheels, especially those for trucks or trailers, might feature solid faces without spokes, most passenger car wheels incorporate spokes into their design.

Five-spoke wheels are a common design choice due to their structural efficiency. This configuration ensures each spoke is supported by two opposing spokes, effectively reducing torsional vibration. While a lower spoke count can theoretically contribute to slightly reduced wheel weight, the impact on overall performance is generally minimal compared to factors like wheel material and construction methods. Ultimately, choosing a wheel with a spoke design that appeals to your personal taste is perfectly acceptable.

#5. Valve Stem: Inflation and Pressure Control

The valve stem is a small but essential component responsible for inflating and deflating the tire. This valve allows air or nitrogen to be introduced into the tire chamber and released as needed to achieve the correct tire pressure.

When properly sealed, the valve stem prevents air or nitrogen leakage, maintaining optimal tire pressure for safe driving and fuel efficiency. It’s a critical element in ensuring consistent tire performance.

Many modern vehicles integrate the valve stem with a tire pressure monitoring system (TPMS). This system provides real-time tire pressure information to the driver, alerting them to any pressure fluctuations that could compromise safety or performance.

Key structural requirements for tire valves include:

- Easy Inflation/Deflation: Designed for convenient air or nitrogen adjustment.

- Leak-Proof Seal: Prevents pressure loss for consistent tire performance.

- Pressure Monitoring Compatibility: Often integrated with TPMS for pressure readings.

- Replaceability: Designed for easy replacement when necessary.

- Standardized Specifications: Manufactured to uniform standards for compatibility and interchangeability.

- Pressure Stabilization: Contributes to maintaining stable inner tube pressure (in tube-type tires).

#6. Hubcaps and Wheel Covers: Decorative and Protective

Hubcaps, also known as wheel covers, are decorative trims that are sometimes added to wheels. They primarily serve an aesthetic purpose, concealing the lug nuts or bolts and enhancing the wheel’s appearance. However, hubcaps also offer a degree of protection, helping to shield the rim from dirt, debris, and road grime.

Hubcaps are designed to fit securely onto the center of the wheel, enduring exposure to various environmental elements. Beyond aesthetics, they can contribute to extending the lifespan of wheel components by protecting lug nuts and bolts from corrosion.

The hub area, often covered by the hubcap, is crucial for wheel rotation and houses the wheel speed sensor, playing a significant role in braking, steering, and traction control systems.

#7. Counterweights (Wheel Balancing Weights): Ensuring Smooth Ride

Counterweights, or wheel balancing weights, are small weights typically made of lead or steel that are attached to the wheel rims. These seemingly insignificant components are essential for wheel balance and ensuring a smooth, vibration-free ride.

Their primary purpose is to counteract any imbalances in the wheel and tire assembly. Even slight imbalances can cause noticeable vibrations at higher speeds, leading to driver discomfort, premature wear on shock absorbers and tires, and reduced driving safety. Proper wheel balancing, achieved through the strategic placement of counterweights, is crucial for optimal vehicle performance and longevity.

#8. Center Bore: Mounting Precision

The center bore is the large hole located in the center of the wheel. It’s designed to precisely fit over the axle hub assembly on the vehicle. The center bore carries the vehicle’s load and ensures the wheel is properly centered on the axle.

The diameter of the center bore must be at least as large as the axle mount to ensure proper wheel fitment. If the center bore is larger than the axle mount, hub-centric rings can be used to fill the gap and guarantee precise centering. This ensures that the wheel’s weight is supported by the axle hub, reducing stress on the lug nuts or bolts.

#9. Center Disc (Plate): Load Distribution

The center disc, also called the “plate,” is the cylindrical section surrounding the center bore. It’s the area where the spokes connect to the hub. The center disc plays a critical role in distributing forces from the axle and braking systems across the wheel structure.

The back of the center disc, known as the mounting pad, rests flush against the axle seat when the wheel is installed. This interface is crucial for transferring load and braking forces effectively.

#10. Lug Holes: Secure Attachment

Lug holes are the precisely drilled holes around the center bore of the wheel. These holes are designed to align with threaded studs protruding from the axle seat. Lug nuts are then tightened onto these studs to securely fasten the wheel to the axle.

In some vehicles, particularly German-made cars, wheel bolts are used instead of lug nuts and studs. Wheel bolts thread directly into the hub, achieving the same secure wheel attachment.

#11. Center Cap: Finishing Touch and Protection

The center cap is a removable cover that fits over the center bore on the exterior face of the wheel. Primarily aesthetic, it provides a clean, finished look to the wheel’s center.

On many modern vehicles, the center cap also serves a practical purpose by protecting the lug nuts or bolts from damage, corrosion, and debris accumulation.

#12. Outer Lip: Style and Depth

The outer lip is the outermost edge of the rim, extending from the wheel face to the outboard edge. The depth of the outer lip is a significant styling element in wheel design. A deep outer lip can enhance the visual appeal of a wheel, but it can also make it more vulnerable to curb damage.

Wheels with deep outer lips may offer slightly less structural support from the spokes in the event of impacts, as the spokes are positioned further inward. On multi-piece wheels, the outer lip is often manufactured as a separate component and then assembled to the rest of the wheel.

#13. Bead Rests: Tire Seating Surface

Bead rests are the specific areas on the rim’s outer surface where the tire beads (the reinforced edges of the tire) seat against the wheel. These surfaces are crucial for creating an airtight seal between the tire and the rim.

Before mounting a tire, it’s essential to clean the bead rests thoroughly to remove any dirt, corrosion, or contaminants that could prevent the tire from sealing properly. A clean bead rest ensures optimal tire pressure retention and prevents air leaks.

#14. Drop Center: Tire Mounting Ease

The drop center is the area of the wheel barrel with the smallest inside diameter. Its design facilitates tire mounting and removal. The location of the drop center relative to the wheel face influences the wheel’s mounting style.

If the drop center is closer to the front face of the wheel, it’s classified as a front mount wheel. Conversely, if the drop center is closer to the back face, it’s considered a reverse mount wheel. These designations primarily affect tire mounting procedures.

#15. Flanges and Beads: Tire Retention

Flanges are the flared edges of the wheel barrel. These flared edges are crucial for preventing the tire from slipping off the rim, especially during cornering or under heavy loads. The outer-facing flanges also contribute to the cosmetic appearance of the wheel.

Just inside the flanges are flat areas called beads. These bead areas are where the tire edges firmly seat against the wheel rim, creating the airtight seal. Mounting humps, which are ridges circling the barrel on both sides of the wheel, further secure the tire beads and prevent them from slipping inward towards the drop center during operation.

FAQs about Car Wheel Parts

What Are The Main Parts In A Car Wheel?

The primary parts of a car wheel are:

- Tire: The rubber component that provides contact with the road.

- Rim: The metal structure that supports the tire.

- Hub: The central part that connects the wheel to the axle.

- Barrel: The inner part of the rim that gives shape to the tire.

- Outer Lip: The outermost edge of the wheel rim.

What Is The Part Of The Car Over The Wheel Called?

The part of the car body located above the wheel is called the fender. In some regions, particularly in the US automotive industry, the term “fender” often refers specifically to the panels over the front wheels. For vehicles with wide bodies that fully enclose the tire, the fender forms the wheel well, which may not be directly visible from above the car body.

What Holds A Wheel On A Car?

Wheels are typically held onto a car using wheel studs and lug nuts. Wheel studs are threaded fasteners permanently attached to the vehicle’s hub. The wheel is placed over the studs, and lug nuts are then screwed onto the studs to securely clamp the wheel against the hub. Some vehicles, especially European models, utilize wheel bolts instead of studs and nuts. Wheel bolts thread directly into the wheel hub to secure the wheel.

What are the Fundamental Parts of a Car Wheel?

The most fundamental components of a car wheel are the tire, the rim, and the hub. The tire wraps around the rim, providing grip and cushioning. The hub is the central mounting point connecting the wheel to the vehicle’s axle.

What are the Components of a 4-Wheel Drive System?

While not directly parts of a car wheel, the components that enable a 4-wheel drive system include: clutch/torque converter, gearbox, propeller shaft, differential, and drive shafts. These components work together to transmit power from the engine to all four wheels, providing enhanced traction and off-road capability.