You might think the car battery is solely responsible for powering your vehicle’s electrical components, but that’s not entirely accurate. While the battery provides the initial jolt needed to start the engine, once your car is running, the alternator takes over. This essential component generates the electricity to keep your car’s electrical systems running and simultaneously recharges the battery. Historically known as a generator, the alternator operates on a similar principle. The engine’s rotation spins pulleys under the hood, which in turn rotates the alternator’s pulley, initiating energy generation.

Working in tandem with the battery, the alternator ensures a constant power supply for all electrical components in your vehicle. The alternator’s output is direct current (DC). The process begins when the alternator pulley rotates, causing alternating current (AC) to flow through a magnetic field, thereby generating an electrical current. This AC current is then converted into DC current by the rectifier, making it usable by your car’s electrical system.

Over the past half-century, alternator technology has seen significant advancements. Early alternators primarily generated current regulated by an external component. The 1990s saw the integration of a built-in regulator, which utilized the warning light system to activate the alternator and start the charging process. Modern vehicles often employ sophisticated smart charge and CANBUS systems, managed by the Engine Control Unit (ECU). These systems are load-sensitive; as the vehicle’s electrical demands increase, the ECU signals the alternator to adjust its charging rate accordingly. This adaptability is crucial as alternators must handle varying electrical loads. However, the complexity of these systems can sometimes lead to misdiagnosis, where a charging issue might be incorrectly attributed to a faulty alternator when the problem lies elsewhere in the system.

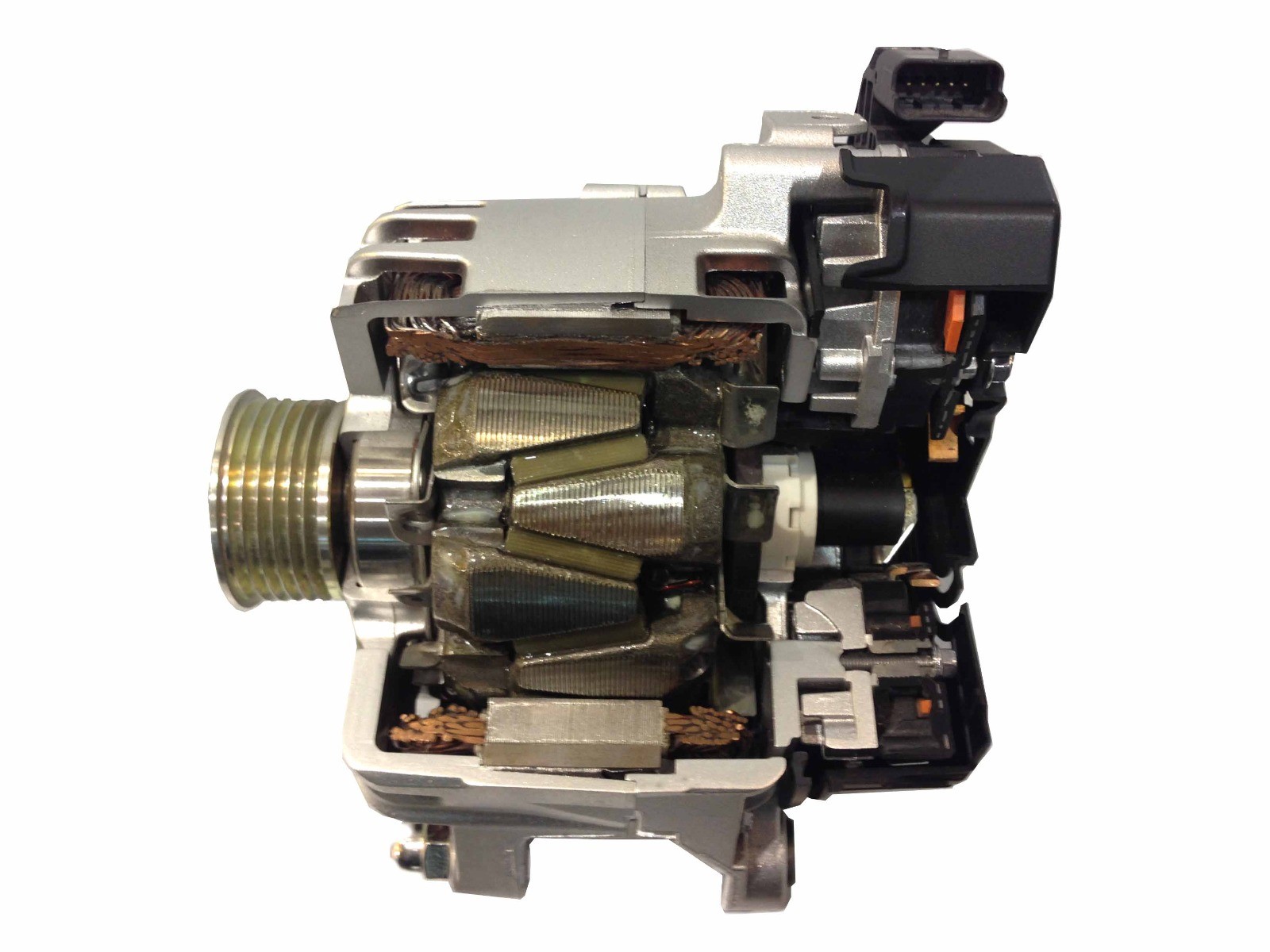

To understand how an alternator functions, it’s helpful to break down its key components. Each part plays a vital role in the electricity generation and regulation process. Below are the essential Parts Of A Car Alternator and their functions:

Key Components of a Car Alternator

Regulator

The regulator is a crucial part of a car alternator as it controls the voltage output. Its primary function is to manage the amount of power distributed from the alternator to the battery. By regulating the voltage, it ensures the battery is charged efficiently without being overcharged, which can damage the battery. Regulators are designed with varying specifications and functionalities depending on the vehicle’s electrical system requirements.

Rectifier

The rectifier is another essential part of a car alternator. It plays the critical role of converting the alternating current (AC) generated by the alternator into direct current (DC). Automotive electrical systems, including the battery, operate on DC power. The rectifier uses diodes to allow current to flow in only one direction, thus transforming AC into the usable DC power required for your vehicle’s electrical components and battery charging.

Rotor

The rotor is the rotating core inside the alternator. It is a key part of a car alternator that spins, driven by the pulley and drive belt system connected to the engine. The rotor functions as a spinning electromagnet. When energized, it creates a magnetic field that is crucial for inducing electrical current in the stator.

Slip Rings

Slip rings are used to conduct electrical current to the rotor. As a part of a car alternator, they provide a continuous electrical connection to the rotating rotor, enabling the flow of direct current to energize the rotor and create the necessary magnetic field for electricity generation.

Slip Ring End Bearing & Drive End Bearing

Bearings are critical for the smooth and efficient operation of the alternator. The slip ring end bearing and drive end bearing are designed to support the rotor shaft, allowing it to rotate freely with minimal friction. These bearings, as parts of a car alternator, ensure the rotor spins smoothly at high speeds, which is essential for efficient electricity generation and the longevity of the alternator.

Stator

The stator is a stationary component that surrounds the rotor. As a vital part of a car alternator, it is composed of multiple coils of wire wound through an iron ring. The stator is where the electrical current is generated. When the rotor’s magnetic field spins within the stator, it induces an alternating current in the stator windings. This AC current is then sent to the rectifier for conversion to DC.

Pulley

The pulley is located on the exterior of the alternator and is connected to the rotor shaft. It is the part of a car alternator that interfaces with the engine’s drive belt system. The engine’s rotation is transferred via the drive belt to the pulley, causing the rotor to spin. This rotation initiates the entire electricity generation process within the alternator.

Drive End Bracket & Slip Ring End Bracket

The drive end bracket and slip ring end bracket are structural parts of a car alternator. These brackets provide the housing and support for the internal components of the alternator, including the rotor, stator, and bearings. They ensure all parts are securely positioned and protected within the alternator assembly, contributing to the overall durability and functionality of the unit.

Understanding the parts of a car alternator and their individual roles highlights the complexity and ingenuity of this vital automotive component. Each part works in harmony to ensure your vehicle’s electrical systems are powered and your battery remains charged, keeping you on the road.