Just like the human body relies on various organs to function, a car motor, also known as an engine, depends on numerous intricate parts working in perfect harmony to power your vehicle. At its core, the engine is an energy conversion machine. It takes chemical energy from fuel and transforms it into mechanical energy, which ultimately propels your car forward. This process is achieved through internal combustion, essentially a series of controlled, miniature explosions within the engine.

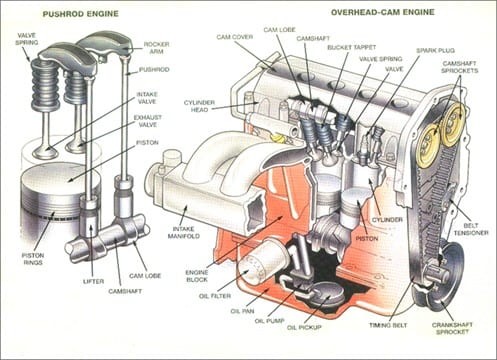

While we often refer to the engine as a single unit, it’s actually a complex assembly of individual components, each playing a vital role. Understanding the names and functions of these Parts Of A Car Motor is crucial for any car owner, not just for basic knowledge, but also for recognizing potential issues and ensuring proper maintenance. Let’s delve into the essential car engine parts and explore their functions, using the diagram below as a visual guide.

Diagram illustrating the main parts of a car motor, including the engine block, cylinders, pistons, crankshaft, camshaft, and cylinder head.

Diagram illustrating the main parts of a car motor, including the engine block, cylinders, pistons, crankshaft, camshaft, and cylinder head.

Key Components of Your Car Motor

Modern car engines are built around robust, sealed metal cylinders. Most cars today utilize engines with four to eight cylinders, although some high-performance vehicles can boast up to twelve or even sixteen. These cylinders are precisely engineered to open and close at specific moments, allowing fuel intake for combustion and the expulsion of exhaust gases. Here are some of the most critical parts of a car motor and their respective roles:

Engine Block: The Foundation

The engine block serves as the central structural element, the very heart of the car motor. Typically constructed from aluminum or cast iron, it’s designed with multiple cylindrical bores that house the cylinders. Beyond this, the engine block incorporates a network of internal passages for coolant and oil circulation. The coolant passages are wider, facilitating engine cooling, while narrower oil passages ensure crucial lubrication of moving parts. Furthermore, the engine block provides mounting points for essential components like the pistons, crankshaft, and camshaft. Depending on the vehicle and engine configuration, it can house four to twelve cylinders arranged in various configurations such as inline, flat, or V-shaped.

Pistons: Translating Combustion into Motion

Pistons are cylindrical components with a flat or slightly domed top surface. Their primary function is to convert the energy released during combustion into mechanical force that drives the crankshaft and, consequently, the wheels of your vehicle. Pistons operate within the cylinders, moving up and down in a reciprocating motion. For every two rotations of the crankshaft, each piston completes two full cycles within its cylinder. Imagine an engine running at 1250 RPM; the pistons in such an engine would travel up and down a staggering 2500 times every minute. To ensure optimal performance and longevity, piston rings are fitted around each piston. These rings are designed to create a tight seal, maximizing compression within the cylinder and minimizing friction caused by the piston’s constant movement against the cylinder walls.

Crankshaft: Converting Linear to Rotational Motion

Located in the lower section of the engine block, nestled within precisely machined crankshaft journals (bearing surfaces), is the crankshaft. This intricately designed and balanced component is connected to the pistons via connecting rods. The crankshaft’s ingenious design transforms the linear, up-and-down motion of the pistons into rotational motion, the kind needed to turn the wheels. Think of a jack-in-the-box mechanism – the crankshaft effectively converts the reciprocating piston movement into the rotation that powers your car, and it does so at engine speed.

Camshaft: Orchestrating Valve Timing

The camshaft’s location can vary depending on the vehicle and engine design. In some older vehicles, it might be found within the engine block, but in many modern cars, particularly those with overhead camshaft (OHC) designs like Dual Overhead Camshaft (DOHC) or Single Overhead Camshaft (SOHC) engines, it’s positioned in the cylinder head(s). The camshaft is supported by a series of bearings that are continuously lubricated by engine oil to ensure smooth operation and longevity. The camshaft’s crucial role is to regulate the precise timing of the intake and exhaust valves. It takes the rotational motion from the crankshaft and converts it into an up-and-down motion to control valve lifters. These lifters, in turn, actuate pushrods, rockers, and ultimately, the valves themselves.

Cylinder Head: The Control Center for Air and Exhaust

Attached securely to the engine block using cylinder head bolts and sealed with a head gasket to prevent leaks, the cylinder head is a complex component. It houses a multitude of parts essential for controlling the flow of air and exhaust gases into and out of the cylinders. These components include valve springs, intake and exhaust valves, lifters, pushrods, rockers, and often the camshaft(s). The cylinder head contains precisely engineered passageways that allow air to enter the cylinders during the intake stroke, where it mixes with fuel. It also features exhaust passages that efficiently remove combustion byproducts – exhaust gases – during the exhaust stroke.

Timing Belt/Chain: Synchronization is Key

For the engine to operate correctly, the camshaft and crankshaft must be precisely synchronized. This synchronization is achieved by either a timing belt or a timing chain. A timing belt is typically made from durable, reinforced rubber with teeth (cogs) that mesh with corresponding pulleys on the camshaft and crankshaft. A timing chain, similar in principle to a bicycle chain, is made of metal links and wraps around toothed pulleys or sprockets. Both the timing belt and timing chain ensure that the valves open and close at the exact right moments in relation to piston movement, which is critical for efficient combustion and engine performance.

Common Issues with Car Motor Parts

Given the high-speed, high-stress environment within a car motor, wear and tear on engine parts is inevitable over time. This wear can lead to various engine problems, often manifesting in noticeable symptoms. Here are some common engine issues related to parts of a car motor and their typical signs:

- Poor Compression: Often caused by worn piston rings, valve issues, or cylinder damage. Symptoms include reduced engine power, engine misfires, and difficulty starting the engine.

- Cracked Engine Block: Can result from overheating or freezing temperatures. Signs include engine overheating, white smoke from the exhaust (indicating coolant burning), and external coolant leaks, often visible on the side of the engine block.

- Damaged Pistons, Rings, and/or Cylinders: Caused by wear, overheating, or lubrication problems. Symptoms may include rattling or knocking noises from the engine, blue smoke emanating from the exhaust pipe (indicating oil burning), rough engine idling, and failure to pass emissions tests.

- Broken or Worn Rods, Bearings, & Pins: Often due to lack of lubrication or excessive engine stress. Symptoms include tapping or ticking sounds from the engine, low oil pressure readings, metal shavings found in the engine oil during an oil change, and rattling noises specifically upon acceleration.

While the internal workings of a car motor might seem complex, its fundamental purpose is straightforward: to generate the power needed to move your vehicle. With so many interconnected car engine parts working in concert to achieve this motion, regular and preventative maintenance is paramount to ensure engine longevity and reliability. Following your vehicle manufacturer’s recommended maintenance schedule, including regular oil changes, coolant and transmission fluid flushes, and timely replacement of belts and hoses, is a proactive approach to preventing serious engine problems and costly repairs down the road.

For expert engine maintenance and repair services, consider Sun Auto Service. Choosing a trustworthy and reputable repair center is essential for ensuring honest and high-quality work. Sun Auto Service prides itself on providing dependable service at affordable prices. They are a Better Business Bureau A+ rated business, employ ASE Certified Technicians, and offer a nationwide warranty, demonstrating their commitment to customer satisfaction. Experience dealership-level service without the premium price – that’s the Sun Auto Service promise.