Every vehicle, from high-performance sports cars to everyday sedans, relies on a fundamental component for mobility: the wheel. It’s an ingenious invention, arguably as impactful as fire itself, allowing us to travel and transport goods with ease. Wheels, along with their tires, are indispensable; without them, our cars would be static displays rather than functional machines. While the core function remains consistent across all vehicles, variations in size, design, and construction cater to different needs and aesthetics.

To deepen your understanding of automotive mechanics and vehicle maintenance, let’s delve into the essential parts of a car wheel. Gaining this knowledge empowers you to better maintain your vehicle, ensuring its longevity and optimal performance.

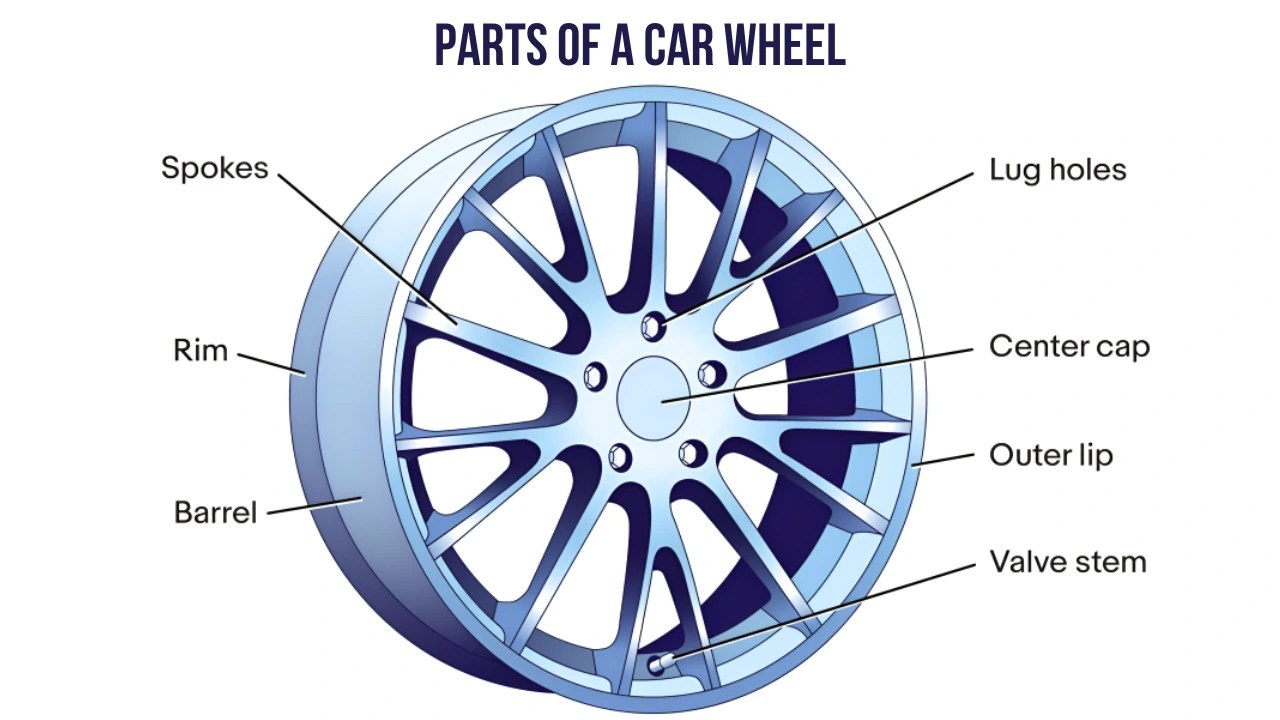

Exploring the Anatomy of a Car Wheel: Parts Diagram and Names

Parts of A Car Wheel Diagram

Parts of A Car Wheel Diagram

Essential Car Wheel Parts Names List:

- Wheel Rim

- Tire

- Valve Stem

- Hubcap / Wheel Cover

- Center Cap

- Lug Nuts

- Wheel Studs

- Wheel Spacers

- Wheel Bearings

- Wheel Seal

- Wheel Bolts

- Wheel Locks

- TPMS Sensor (Tire Pressure Monitoring System)

- Rim Flange

- Bead

- Wheel Balancing Weights

- Wheel Valve Cap

- Dust Cap

Understanding the Core Components of a Wheel

A car wheel assembly comprises several key parts, primarily categorized into three main components: the tire, the rim, and the hub. The tire, encompassing the wheel’s circumference, is mounted onto the rim and provides the crucial grip between the wheel and the road surface. The hub serves as the central point of connection, attaching the wheel to the vehicle’s axle.

#1. The Tire: Your Vehicle’s Contact Point

The tire is arguably the most recognized part of the wheel. Its function is straightforward yet critical: to provide cushioning and traction. Essentially, tires create a smooth ride by utilizing air pressure to absorb road imperfections.

Modern pneumatic tires, developed roughly 70 years ago, revolutionized driving comfort and safety compared to their solid rubber predecessors. Selecting the correct tire type for your vehicle and driving conditions is paramount for safety and performance.

Tires are engineered to maintain grip on various surfaces, including wet, icy, and snowy roads, thereby enhancing vehicle handling and control in challenging conditions.

Related Exploration: To further your knowledge, explore our detailed article on “Tire Parts: What are the Different Parts of a Tire?” for an in-depth look at tire construction.

#2. The Rim: The Wheel’s Structural Foundation

If the tire is the skin of the wheel assembly, the rim forms its skeletal structure. The tire encases the rim, which provides support, shape, and the airtight chamber necessary for inflation. Rims are typically manufactured from durable materials like steel or lightweight aluminum alloys and are available in a vast array of designs.

Rim aesthetics range from utilitarian steel wheels often concealed by plastic hubcaps or wheel covers to visually striking polished chrome rims. Design choices often reflect vehicle type; truck rims, for instance, prioritize strength and load-bearing capacity over purely decorative features. Rim diameter and width are crucial measurements that dictate compatible tire sizes and styles.

#3. The Hub: The Center of Wheel Mechanics

The hub is the central component of the wheel, serving as the attachment point for the rim. It’s also the housing for critical braking components, including brake pads, calipers, and rotors. The hub connects directly to the axle, enabling both vehicle movement and braking.

The tire and rim assembly are secured to the hub, typically using wheel studs and lug nuts. The hub is the core of the wheel’s mechanical function, ensuring secure attachment to the vehicle and facilitating controlled motion. Key features of the hub include the center bore, center disc, lug holes, and often a center cap for protection and aesthetics.

#4. Spokes: Structural and Stylish Elements

Spokes are structural members that bridge the hub and the rim, providing essential wheel integrity. They contribute significantly to the wheel’s overall strength and, along with the hub, form the visible face of the wheel.

In multi-piece wheel designs, the spoke section, often referred to as the “wheel face,” is manufactured separately and then bolted to the inner barrel.

Beyond their structural role, spokes are a major design element, contributing significantly to a wheel’s unique appearance. Custom wheels offer diverse spoke styles, varying in number, width, shape, and pattern for visual appeal. Some heavy-duty truck or trailer wheels may even feature solid faces without any spokes for maximum strength.

Five-spoke wheel designs are a common choice in automotive engineering due to their balanced structural properties. Each spoke is supported by two opposing spokes, effectively minimizing torsional vibration. While a lower spoke count can slightly reduce wheel weight, the materials and manufacturing processes employed have a more substantial impact on overall wheel weight and performance. Ultimately, personal preference often dictates spoke design choice.

#5. Outer Lip: Defining Wheel Depth

The outer lip is the forward-facing edge of the wheel, positioned in front of the spokes. The “dish” of a wheel, or its depth, becomes noticeable when the spokes are set significantly back from this outer edge, creating a “deep-dish” wheel.

Deep-dish designs are primarily for aesthetic purposes, enhancing the visual appeal of the wheel. However, a deeper dish can make the wheel face more susceptible to damage from impacts.

#6. Barrel: The Tire Mounting Structure

The barrel is the outermost section of the wheel, engineered to create the necessary structure for tire mounting. It incorporates several key features. The narrowest inner diameter of the barrel is known as the drop center.

The position of the drop center relative to the wheel face determines if it’s a front mount or reverse mount wheel. A drop center closer to the front face indicates a front mount, while a position closer to the back face signifies a reverse mount.

The barrel edges are flared outwards to form flanges. These flanges are crucial for retaining the tire, preventing it from slipping off the rim. The outer flanges also contribute to the wheel’s cosmetic appearance.

#7. Beads: Tire Seating Surfaces

Positioned just inside the flanges are flat surfaces called beads. These are the critical areas where the tire edges, or beads, seat firmly against the wheel, creating an airtight seal.

#8. Flanges: Tire Retention Edges

Flanges are the flared edges located along both the inboard and outboard sides of the rim. Their primary function is to securely hold the tire in place, preventing it from detaching from the wheel during operation.

#9. Mounting Humps: Bead Slip Prevention

Mounting humps are small ridges that run along the inner circumference of each bead seat. These subtle features play a vital role in preventing tire bead slippage and maintaining a secure tire position against the wheel, particularly under stress.

#10. Drop Center: Facilitating Tire Installation

The drop center, the narrowest section within the barrel, is specifically designed to simplify tire mounting. It allows technicians to install tires onto the wheel without excessively stretching the bead wires, making the process more manageable and reducing the risk of tire damage during mounting.

#11. Center Cap: Protective and Cosmetic Cover

The center cap is a removable component that covers the center bore on the wheel’s exterior. In modern vehicles, center caps often serve a dual purpose, protecting the lug nuts from dirt, debris, and potential damage, while also contributing to the wheel’s overall aesthetic finish.

#12. Valve Stem: Tire Inflation and Pressure Monitoring

The rim incorporates a dedicated hole for the valve stem, a crucial component during tire mounting. The valve stem is a specialized metal air valve used to inflate the tire to the correct pressure and allows for pressure monitoring. Many modern vehicles are equipped with TPMS (Tire Pressure Monitoring System) sensors integrated within the valve stem to alert drivers to pressure fluctuations.

With this comprehensive understanding of car wheel parts, you are now better equipped to appreciate the complexity and engineering behind this essential vehicle component. For further exploration into automotive systems, we encourage you to read our detailed articles on “car engine parts” and “car parts” for a broader perspective on vehicle mechanics.

Frequently Asked Questions (FAQs)

What Are The Main Parts Of A Car Wheel Assembly?

Key Wheel Components: The primary parts of a car wheel assembly are: 1. The Tire: Providing grip and cushioning. 2. The Rim: Structurally supporting the tire. 3. The Hub: Connecting the wheel to the axle and housing braking components. 4. The Barrel: Shaping the tire and providing mounting structures. 5. The Outer Lip: The wheel’s forward edge defining its depth.

What Is The Panel Above The Car Wheel Called?

The panel situated above the car wheel is typically referred to as the fender. In contemporary US automotive terminology, “fenders” often denote the panels specifically positioned above the front wheels. For vehicles with wide-body designs that fully enclose the tire, the fender forms the wheel well, encasing the tire and often not directly visible from above the vehicle’s body.

How Is A Wheel Held Onto A Car?

Wheels are typically secured to the vehicle using wheel studs and lug nuts. Wheel studs are threaded fasteners semi-permanently mounted to the vehicle’s hub, often through the brake drum or rotor. Lug nuts are then tightened onto the wheel studs, firmly clamping the wheel to the hub and ensuring secure attachment.

What Are The Basic Components Of A Car Wheel?

The fundamental components of a car wheel are: the tire, the rim, and the hub. The tire, which defines the wheel’s width, encircles the rim and provides essential road grip.

What Are The Components Of A 4-Wheel Drive System?

Key components of a 4-wheel drive system include: the clutch/torque converter, gearbox, propeller shaft, differential, and drive shafts. The driveline in a 4WD system serves multiple functions, including allowing the engine to operate even when the vehicle is stationary and distributing power to all four wheels for enhanced traction.

Related Post