On-Board Diagnostics (OBD2) systems are integral to modern vehicles, providing a standardized way to access vehicle data for diagnostics and monitoring. Parameter IDs (PIDs) are the key to unlocking this data, allowing you to request specific information from your car’s computer. Whether you’re a car enthusiast, a mechanic, or an engineer, understanding OBD2 PIDs is crucial. Resources like the Wikipedia OBD-II PIDs page offer a starting point, but this guide aims to provide a more in-depth and practical understanding.

Understanding OBD2 and PIDs

OBD2 is essentially your vehicle’s self-diagnostic system. It monitors various parameters within your car and can report issues through Diagnostic Trouble Codes (DTCs), often indicated by the check engine light. Beyond error codes, OBD2 also provides access to a wealth of real-time data through PIDs. These PIDs are standardized codes defined in the SAE J1979 standard, ensuring compatibility across different vehicle makes and models.

Think of PIDs as addresses for specific sensors and data points within your vehicle. Requesting a PID is like asking your car’s computer, “Hey, what’s the current engine speed?” or “What’s the coolant temperature?”. The beauty of OBD2 is its standardization. While manufacturers may have proprietary extensions, the core set of PIDs for basic vehicle parameters remains consistent, making tools and knowledge broadly applicable.

How OBD2 PIDs Work: Requests and Responses

To retrieve data using OBD2 PIDs, tools like OBD2 scanners, interfaces, or data loggers are used. These devices communicate with the vehicle’s computer via the OBD2 port, typically located under the dashboard. The communication happens over the Controller Area Network (CAN) bus, a robust communication protocol used in vehicles.

The process involves sending a request and receiving a response. Let’s take an example: requesting PID 0D, which represents Vehicle Speed.

An OBD2 tool sends a CAN frame with a specific format. A typical request frame to retrieve PID 0D might look like this:

CAN ID: 7DF

Data Payload: 02 01 0D AA AA AA AA AA7DFis the functional request ID in OBD2.02indicates the number of bytes following.01is the service ID for “Show current data”.0Dis the PID for Vehicle Speed.AA AA AA AA AAare padding bytes.

If the vehicle supports PID 0D, it will respond with a CAN frame. A typical response frame might be:

CAN ID: 7E8

Data Payload: 03 41 0D XX AA AA AA AA7E8is a typical response ID (request ID + 8).03indicates the number of bytes following.41is the positive response service ID (request service ID + 40).0Dis the PID being responded to.XXis the data byte(s) containing the vehicle speed in hexadecimal format.AA AA AA AAare padding bytes.

The crucial part is decoding XX to a physical value. For Vehicle Speed (PID 0D), the value XX is a single byte representing speed in km/h. If XX is 12 in hexadecimal (which is 18 in decimal), the vehicle speed is 18 km/h. Many PIDs involve scaling and offsets to convert the raw hexadecimal data into meaningful units.

OBD2 PID Table: A Practical Overview

Understanding the structure of OBD2 PID data is essential for effective data interpretation. While resources like the Wikipedia OBD-II PID list provide comprehensive lists, a more practical table format, similar to CAN database conventions, can be more user-friendly for implementation. This format typically includes:

- PID (dec/hex): The PID number in decimal and hexadecimal.

- Name: A descriptive name of the parameter.

- Bit start: The starting bit position of the data within the response.

- Bit length: The number of bits the data occupies.

- Scale: The factor to multiply the raw value by.

- Offset: The value to add to the scaled value.

- Min/Max: The valid range of the physical value.

- Unit: The physical unit of the parameter.

For example, consider Engine Speed (PID 0C). According to the table:

| PID dec | PID hex | Name | Bit start | Bit length | Scale | Offset | Min | Max | Unit |

|---|---|---|---|---|---|---|---|---|---|

| 12 | 0C | Engine speed | 31 | 16 | 0.25 | 0 | 0 | 16384 | rpm |

If the OBD2 response payload for PID 0C is 04 41 0C 0A 0C AA AA AA, the data bytes are 0A 0C. Converting the hexadecimal 0A0C to decimal gives 2572. Using the scale and offset:

Physical Value = Offset + (Scale * Raw Decimal Value)

Engine Speed = 0 + (0.25 * 2572) = 643 rpmThis calculation demonstrates how to extract the engine speed from the raw OBD2 response using the provided table parameters. This structured approach is often more intuitive than navigating the detailed descriptions on pages like the Wikipedia OBD-II PIDs list, especially when programmatically decoding multiple PIDs.

Programmatic Access to OBD2 PIDs

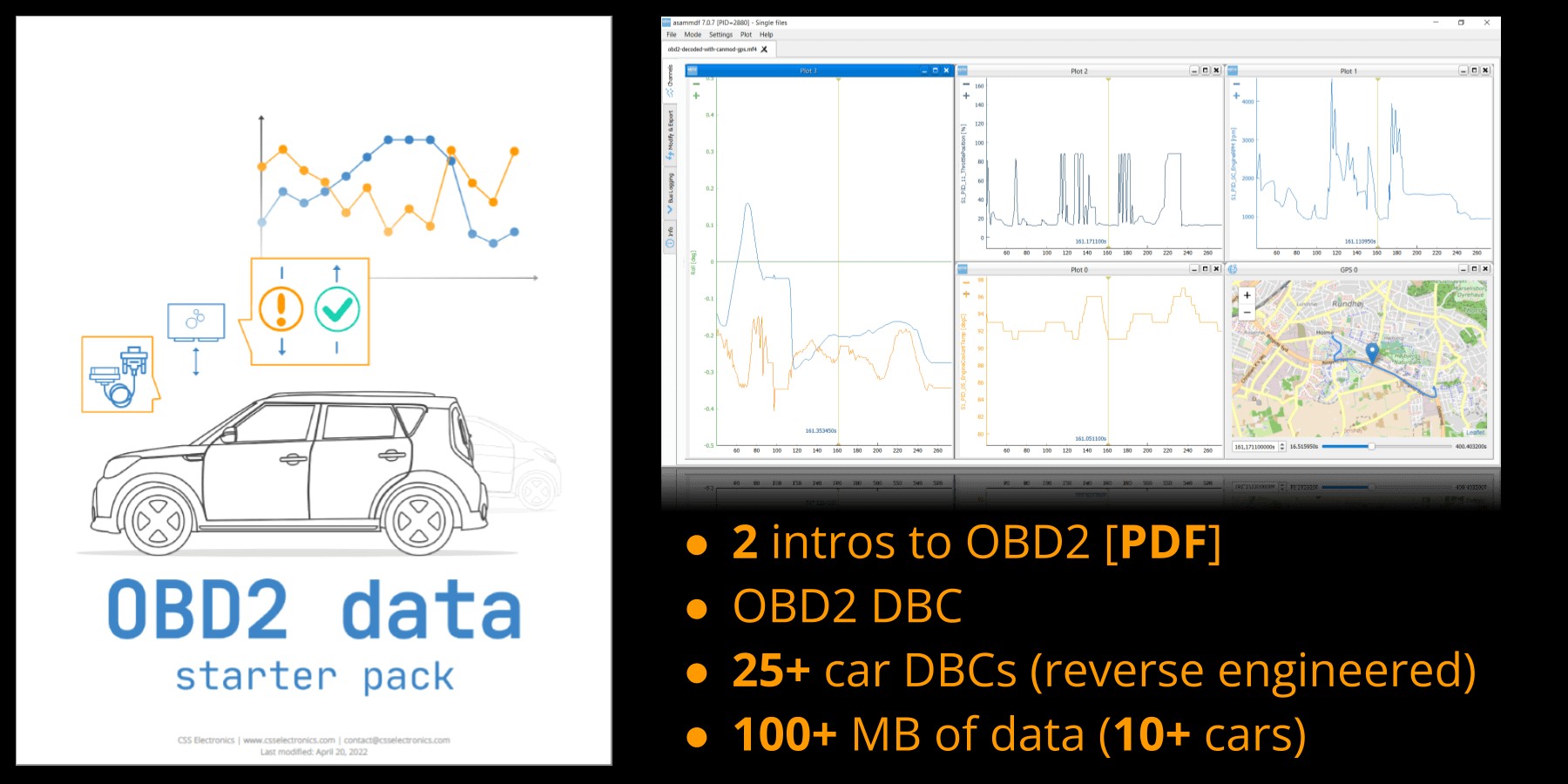

For developers and engineers, programmatic access to OBD2 data is often desired. To facilitate this, resources like DBC (CAN database) files and CSV tables are invaluable.

- DBC files: These files provide a structured way to define the decoding logic for OBD2 PIDs, including bit positions, scaling, and units. They are used with CAN bus software tools to automatically decode raw CAN data into human-readable values.

- CSV tables: CSV (Comma Separated Values) files offer a simpler, text-based format to store PID information. These are useful for scripting and custom implementations where you need to parse and decode OBD2 data in your own programs.

J1939 data pack

J1939 data pack

Tools and APIs are available to work with both DBC and CSV formats, allowing you to efficiently process OBD2 data from log files or live streams. Open-source Python APIs, for example, can be used to load and decode OBD2 data, making it easier to create custom dashboards or integrate OBD2 data into other systems.

Conclusion

OBD2 PIDs are the standardized language for accessing a wealth of data from your vehicle. While resources like the Wikipedia OBD-II PIDs page are valuable for understanding the breadth of available parameters, a deeper understanding of request/response mechanisms, data decoding, and practical table formats is essential for effective utilization. By leveraging tools, tables, and programmatic resources, you can unlock the power of OBD2 data for diagnostics, monitoring, and a deeper understanding of your vehicle’s operation.

For further exploration, consider downloading sample OBD2 data and DBC files to practice decoding PIDs yourself. This hands-on experience will solidify your understanding and enable you to effectively work with OBD2 data in your projects.